Why Chemical Pumps Are Essential for Efficient Water Treatment Solutions

In the modern context of water treatment, the efficiency and effectiveness of chemical dosing are paramount to ensuring water quality and safety. According to a report by the World Health Organization, an estimated 2 billion people worldwide lack access to safely managed drinking water services. To tackle such challenges, the use of chemical pumps for water treatment has become essential. These specialized pumps ensure precise chemical dosing, which is critical in processes such as disinfection, coagulation, and pH adjustment.

Recent industry studies indicate that the adoption of advanced chemical pump technologies can enhance operational efficiency by up to 25%, while also reducing chemical waste and operational costs. For instance, a report by MarketsandMarkets highlights that the global chemical pump market is projected to grow from USD 27.5 billion in 2020 to USD 35.3 billion by 2025, driven by increasing demand for efficient water treatment solutions. As municipalities and industries alike strive to meet stricter water quality regulations, the role of chemical pumps in optimizing treatment processes cannot be overstated.

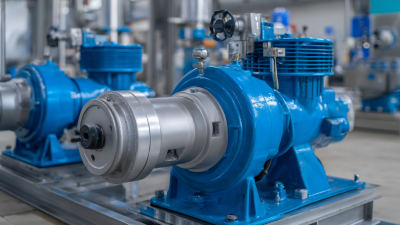

The Role of Chemical Pumps in Modern Water Treatment Facilities

Chemical pumps play a pivotal role in modern water treatment facilities by ensuring the accurate and efficient dosing of various chemicals essential for water purification. These pumps are designed to handle a range of liquids, from corrosive chemicals like chlorine to less hazardous ones like flocculants. Their ability to deliver precise flow rates is crucial for maintaining optimal chemical concentrations, which directly affects the effectiveness of the treatment process. Without reliable chemical pumps, fluctuations in chemical dosing could lead to inadequate treatment or excessive chemical use, both of which can compromise water quality.

In addition to accuracy, chemical pumps offer adaptability in treatment processes. They can be integrated with automated control systems that monitor water quality parameters in real time. This integration enables facilities to adjust chemical dosing dynamically based on changing conditions, such as fluctuations in water contaminants or variations in flow rates. Consequently, chemical pumps not only enhance the efficiency of water treatment but also contribute to cost savings by minimizing chemical usage and reducing waste. The versatility and reliability of these pumps make them indispensable in achieving the high standards required in modern water treatment facilities.

Water Treatment Chemical Pump Efficiency

Key Features of Chemical Pumps for Enhanced Efficiency

Chemical pumps play a pivotal role in enhancing the efficiency of water treatment solutions. One of the key features of highly efficient chemical pumps is their ability to maintain precise control over flow rates, which is crucial for dosing various chemicals with accuracy. According to a report by the Global Water Intelligence, optimizing chemical dosing can reduce chemical consumption by up to 30%, resulting in significant cost savings for water treatment facilities.

Another critical aspect is the materials used in the construction of chemical pumps. Advanced materials such as high-density polyethylene and fluoropolymers improve resistance to corrosive chemicals, extending the lifespan of the equipment. The Water Environment Federation indicates that using corrosion-resistant pumps not only lowers maintenance costs but also improves system reliability, with downtime reduced by an estimated 25% in some cases.

Additionally, the integration of smart technologies in chemical pumps enables real-time monitoring and remote operation, which further enhances operational efficiency. A study by the Association of Water Technologies highlights that automated systems can improve the response time to chemical imbalances, increasing overall treatment effectiveness. The implementation of these advanced features makes chemical pumps indispensable in the realm of water treatment, ensuring both efficiency and sustainability.

Selecting the Right Chemical Pump for Your Water Treatment Needs

Selecting the right chemical pump for your water treatment needs is crucial to ensure optimal performance and reliability. The first step in this process is to assess the specific requirements of your water treatment system, including flow rate, pressure, and the types of chemicals that will be handled. Different chemical pumps, such as diaphragm, peristaltic, or centrifugal pumps, offer various advantages depending on the application. For instance, if precision dosing of chemicals is essential, a diaphragm pump may be the best choice due to its ability to provide accurate flow control.

Additionally, factors like the compatibility of pump materials with the chemicals being transported, as well as the operational environment, must be considered. For corrosive or abrasive substances, robust materials and protective coatings are critical to ensure longevity and reduce maintenance costs. Evaluating the total cost of ownership, including installation and energy efficiency, can also guide you in making a cost-effective decision. Ultimately, the right chemical pump not only enhances the efficiency of your water treatment solutions but also contributes to a more sustainable operation.

Why Chemical Pumps Are Essential for Efficient Water Treatment Solutions

| Type of Chemical Pump | Flow Rate (GPH) | Pressure Range (PSI) | Common Applications | Material Compatibility |

|---|---|---|---|---|

| Diaphragm Pump | 0-100 | 0-60 | Acid and caustic dosing | PVC, PTFE |

| Peristaltic Pump | 0-200 | 0-30 | Chemicals and wastewater treatment | Silicone, Santoprene |

| Gear Pump | 0-150 | 0-100 | Flocculant dosing | Stainless steel, Cast iron |

| Centrifugal Pump | 0-500 | 0-150 | General water transfer | Noryl, Polypropylene |

| Magnetic Drive Pump | 0-100 | 0-50 | Hazardous chemicals | PP, PVDF |

Maintenance Best Practices for Longevity of Chemical Pumps

Maintaining the longevity of chemical pumps is crucial for ensuring optimal performance in water treatment solutions. Regular inspection and maintenance practices can significantly reduce the risk of unexpected failures. One important aspect is the routine checking of seals and gaskets, which are critical for preventing leaks. Operators should also monitor the pump's operating parameters—such as pressure and flow rates—frequently, as deviations could indicate underlying issues that need attention.

Another key maintenance practice involves cleaning the pump and its components. Accumulation of sediment or chemical residues can lead to reduced efficiency and potential damage. It is advisable to develop a cleaning schedule, tailored to the specific environmental conditions and chemicals handled, to prevent any build-up. Additionally, keeping a detailed maintenance log helps in identifying recurring issues and planning timely interventions, thus extending the lifespan of the pumps significantly.

Emerging Innovations in Chemical Pump Technology for Water Treatment

Emerging innovations in chemical pump technology are playing a pivotal role in enhancing water treatment solutions. As the industry faces increasing challenges from chemicals of emerging concern (CECs), the need for advanced pumping systems becomes critical. Modern chemical pumps are being designed with smart features that enable precise dosage and improved efficiency, which is essential for sustainable water purification processes.

The integration of AI-powered systems into pump technology marks a significant trend in water management. These innovations allow for operational intelligence that optimizes performance and minimizes waste. Additionally, niche markets, such as progressive cavity pumps, are projected to experience substantial growth, reflecting the rising demand for reliable and effective water management solutions. This growth aligns with global initiatives emphasizing the importance of water security and sustainable practices, ensuring that chemical pumps remain a cornerstone of modern water treatment strategies.

Related Posts

-

Maximizing Efficiency: The Role of Chemical Injection Pumps in Reducing Operational Costs by 20% in the Oil Industry

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.