The Ultimate Guide to Choosing the Right Chemical Pumps for Your Needs

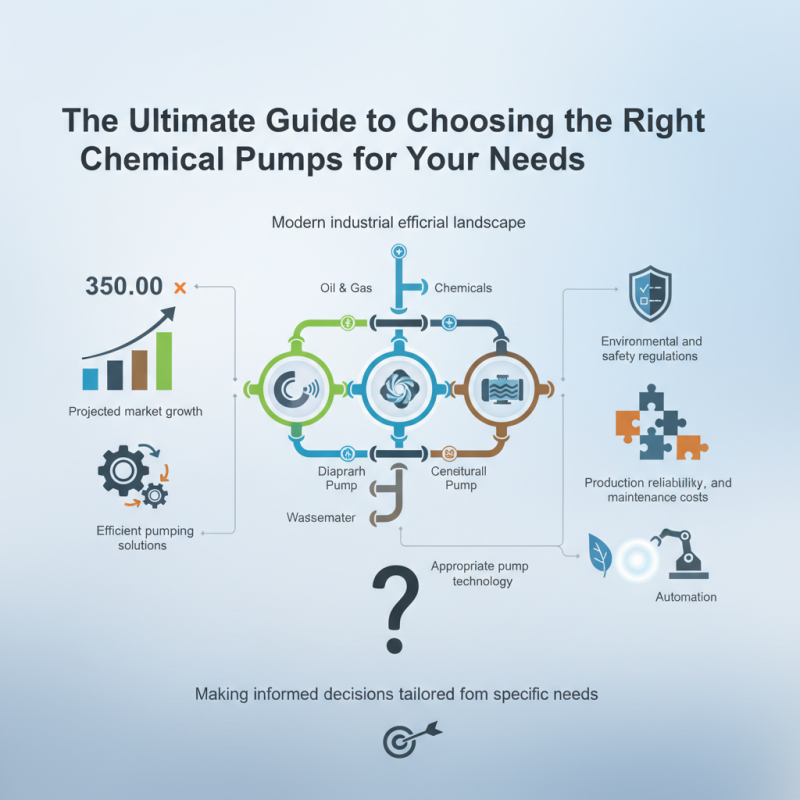

In the modern industrial landscape, the selection of proper chemical pumps is critical for optimizing operational efficiency and ensuring safety in a variety of applications. According to a recent industry report by MarketsandMarkets, the global chemical pump market is projected to reach $5.9 billion by 2026, indicating a steady growth driven by advancements in technology and the increasing demand for efficient pumping solutions across sectors such as oil and gas, chemicals, and wastewater treatment.

Understanding the myriad types of chemical pumps, including diaphragm, centrifugal, and peristaltic pumps, is essential for industries to not only meet operational demands but also to comply with stringent environmental and safety regulations. The right choice of chemical pumps can enhance production reliability, reduce downtime, and minimize maintenance costs. Furthermore, as industries adapt to new challenges such as sustainability initiatives and the push towards automation, selecting the appropriate pump technology becomes increasingly vital. Thus, this guide aims to provide comprehensive insights into the critical factors necessary for making informed decisions in the selection of chemical pumps tailored to specific needs.

Understanding the Different Types of Chemical Pumps Available in the Market

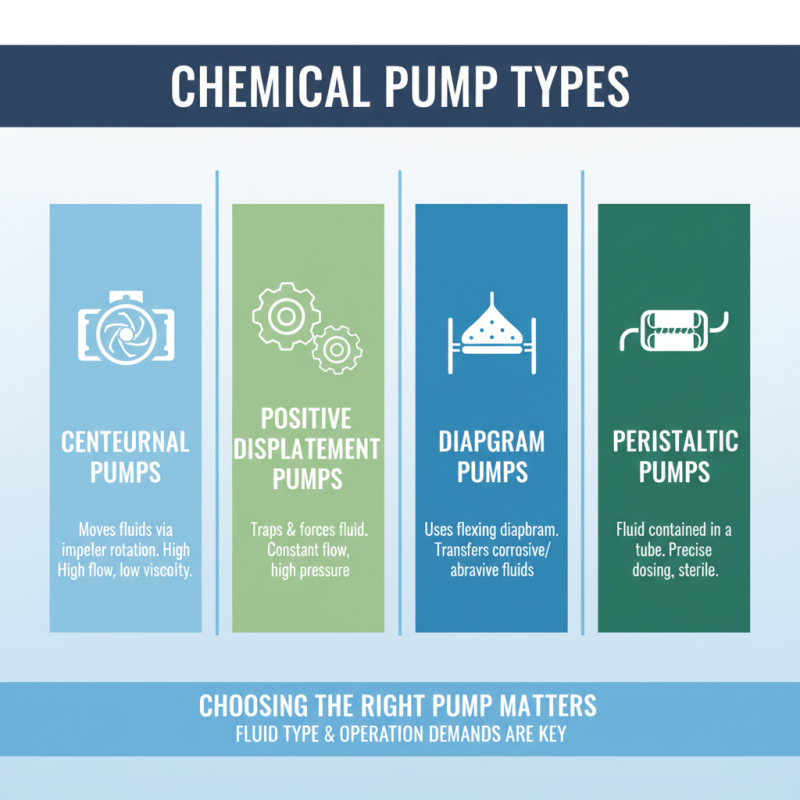

When it comes to selecting chemical pumps, understanding the various types available on the market is crucial for making an informed decision. Chemical pumps can be broadly categorized into four main types: centrifugal, positive displacement, diaphragm, and peristaltic pumps. Each type has its unique features tailored to specific applications, which makes it essential to choose the right one based on the characteristics of the fluid being handled and the demands of the operation.

Centrifugal pumps, commonly used in many industrial applications, operate by converting rotational energy into kinetic energy, providing a steady flow of fluid. They are ideal for low-viscosity liquids and are known for their efficiency in transferring fluids over longer distances. On the other hand, positive displacement pumps are more suitable for high-viscosity fluids, as they operate by trapping a fixed amount of fluid and forcing it through the discharge. This makes them a popular choice for applications that require precise flow control.

Diaphragm pumps utilize a flexible membrane to separate the pumping chamber from the fluid, making them excellent for handling hazardous materials without contamination. Lastly, peristaltic pumps are ideal for gentle, precise transfer of shear-sensitive fluids, such as pharmaceuticals or food products. By understanding these different types of chemical pumps and their specific applications, you can effectively identify the best option for your needs while ensuring optimal performance and safety in handling chemicals.

Key Parameters to Consider When Selecting Chemical Pumps for Your Application

When selecting chemical pumps for specific applications, several key parameters must be considered to ensure optimal performance and reliability. One of the fundamental attributes is the pump's material compatibility. According to a report by the Chemical Engineering Magazine, about 70% of pump failures in chemical processing are due to material incompatibility. Materials such as stainless steel, polypropylene, or PTFE should be evaluated based on the type of chemicals being handled, temperature ranges, and pressure conditions. Ensuring that the pump construction material can withstand the corrosive nature of chemicals used is critical for longevity and operational safety.

Another essential factor is the pump's capacity and flow rate. The Hydraulic Institute suggests that accurately sizing your pump to meet the required flow rate can increase efficiency by up to 20%. Understanding the specific flow needs of your application—whether consistent or variable—is vital. Additionally, the total dynamic head (TDH) that the pump must overcome is significant, as it largely influences the energy consumption and operational costs. By carefully assessing these parameters, you can enhance both the performance and lifespan of your chemical pumping systems, ultimately leading to more efficient processes in chemical operations.

Evaluating Pump Materials: Corrosive Resistance and Durability Factors

When selecting chemical pumps, one of the most critical factors to consider is the materials used in their construction, particularly their resistance to corrosion and overall durability. Chemicals can be aggressive and may cause rapid degradation of standard materials, leading to system failures and costly downtime. Therefore, understanding the nature of the substances being pumped is essential. For instance, while some pumps may be suitable for less aggressive fluids, others require specialized materials such as high-grade stainless steel, PTFE, or specialized alloys that can withstand harsh environments.

In addition to chemical compatibility, evaluating the durability of pump materials is vital for ensuring longevity and reliability. Factors such as temperature variations, pressure conditions, and mechanical stresses can significantly impact a pump's lifespan. Materials that exhibit excellent corrosion resistance may still be vulnerable to wear under certain operational conditions. Therefore, it is crucial to assess the specific application requirements and environmental factors before making a decision. By focusing on both corrosive resistance and durability, users can ensure they choose the right pump materials, ultimately leading to more efficient operations and reduced maintenance costs.

The Ultimate Guide to Choosing the Right Chemical Pumps for Your Needs

| Pump Type | Material | Corrosion Resistance | Durability | Ideal Applications |

|---|---|---|---|---|

| Centrifugal Pump | Stainless Steel | High | Good | Water Treatment |

| Diaphragm Pump | PTFE | Excellent | Very Good | Chemical Processing |

| Peristaltic Pump | PVC | Moderate | Good | Food Processing |

| Gear Pump | Aluminum | Low to Moderate | Good | Oil Transfer |

| Magnetic Drive Pump | Polypropylene | High | Very Good | Hazardous Chemicals |

Industry Standards and Regulations Impacting Chemical Pump Selection

When selecting chemical pumps, understanding the industry standards and regulations that govern their use is crucial. Various standards, such as those established by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), provide benchmarks for safety, performance, and quality assurance in chemical pumping applications. Adhering to these standards not only ensures compliance but also helps in choosing pumps that are reliable and suited for specific chemical handling needs. Each industry may have its own set of regulatory requirements that dictate the materials, designs, and operational parameters of pumps, influencing the decision-making process.

Additionally, environmental regulations play a significant role in the selection of chemical pumps. Regulations aimed at reducing emissions and ensuring safe disposal of hazardous materials require pumps that minimize leaks and facilitate safe transfer of corrosive or toxic substances. For example, standards pertaining to containment and spill prevention must be considered, emphasizing the need for double-sealed designs or secondary containment systems. By staying informed on both industry-specific and environmental regulations, businesses can select pumps that not only meet operational needs but also align with legal requirements, ultimately enhancing operational efficiency and safeguarding public health.

The Impact of Industry Standards on Chemical Pump Selection

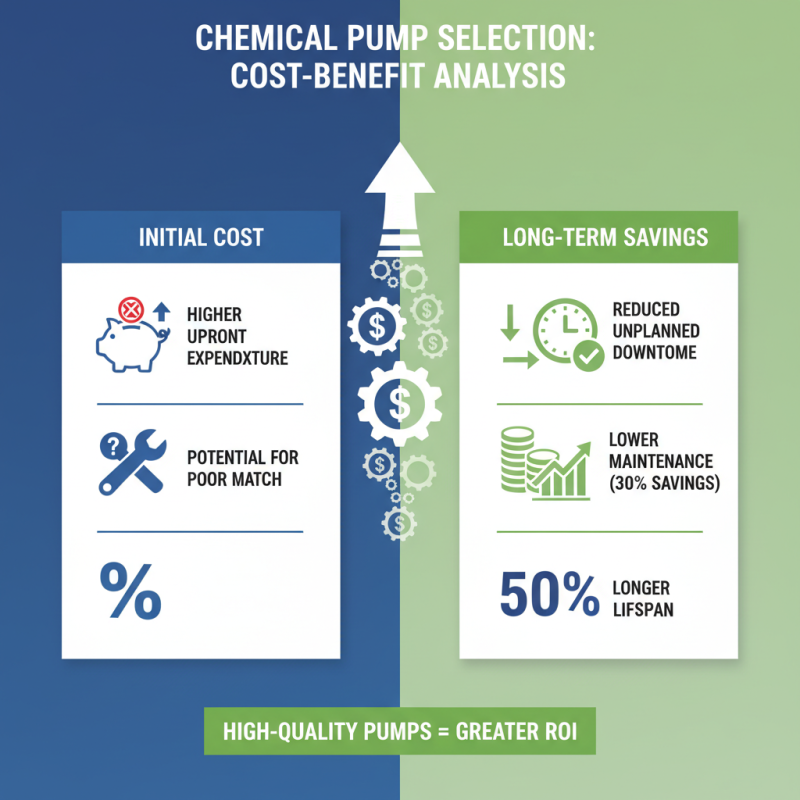

Cost-Benefit Analysis: Balancing Initial Costs with Long-Term Performance

When selecting chemical pumps, a key consideration is the cost-benefit analysis, which involves comparing initial purchase costs with long-term operational efficiency and performance. According to a report from the Global Chemical Pump Market, approximately 30% of maintenance costs can be attributed to poorly matched pumps. Investing in a high-quality pump may require a higher upfront expenditure, but the reduction in unplanned downtime and maintenance can lead to significant savings over time. Studies show that a reliable pump with a longer lifespan can outperform cheaper alternatives by up to 50%, yielding substantial cost benefits in operational environments.

Additionally, energy consumption plays a critical role in the total cost of ownership for chemical pumps. Research indicates that energy costs can account for up to 60% of the lifetime cost of pump operation. Hydraulic efficiency is essential, as pumps that are designed for specific applications can minimize energy wastage. The U.S. Department of Energy’s Industrial Technologies Program suggests that optimizing pump systems can reduce energy consumption by 20-50%, translating into considerable savings. Therefore, while the initial investment may be considerable, the long-term benefits of efficiency, reliability, and lower lifetime costs make it crucial for companies to carefully evaluate their choices in chemical pumps.

Related Posts

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

-

Understanding the Role of Chemical Pumps in Modern Industrial Applications

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

The Ultimate Guide to Choosing the Right Fluid Pumps for Your Industrial Needs

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.