Top 5 Electric Diaphragm Pumps: Key Features and Benefits Explained

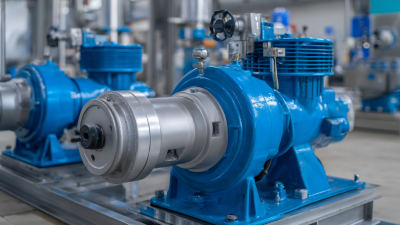

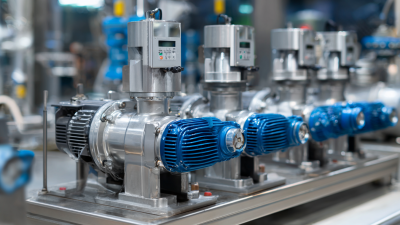

In recent years, the demand for efficient and reliable fluid transfer solutions has led to the rise of the electric diaphragm pump. These innovative pumps are designed to handle a wide range of liquids, making them ideal for various applications across industries such as agriculture, chemical processing, and wastewater management. With their unique diaphragm mechanism and electric drive, electric diaphragm pumps offer significant advantages over traditional pumping systems, including improved energy efficiency, reduced maintenance needs, and superior chemical compatibility.

This article explores the top five electric diaphragm pumps currently available in the market, highlighting their key features and benefits. Each pump represents a unique solution that caters to specific requirements, whether it be for high-flow capabilities, precision dosing, or enhanced durability. By understanding the strengths of these electric diaphragm pumps, users can make informed decisions to optimize their operational processes, ensuring that they choose the right equipment for their specific needs. As we delve into the details of these pumps, we will uncover how electric diaphragm pumps can enhance efficiency and reliability in fluid transfer applications.

Top 5 Electric Diaphragm Pumps: An Overview of Essential Features

Electric diaphragm pumps are increasingly recognized for their efficiency and versatility in various industrial applications. These pumps are designed to handle a wide range of fluids, including corrosive and abrasive liquids, which makes them suitable for chemical processing, water treatment, and food and beverage industries. According to a recent industry report, the market for electric diaphragm pumps is projected to grow at a CAGR of 6.5% over the next five years, driven by advancements in technology and the growing demand for reliable fluid transfer solutions.

One of the essential features of electric diaphragm pumps is their ability to operate dry without causing damage to the pump itself. This is particularly important in applications where fluid availability can be inconsistent. Additionally, their self-priming capability ensures that they can be easily installed and maintained, making them user-friendly. Energy efficiency is another significant benefit; these pumps consume up to 50% less energy compared to traditional pumps, resulting in reduced operational costs. Furthermore, electric diaphragm pumps often come with built-in safety features that prevent leaks and spills, aligning with industry standards for safety and environmental responsibility.

The versatility of electric diaphragm pumps is further enhanced by their compatibility with various control systems, allowing for automated operations in advanced manufacturing environments. They can accommodate various flow rates and pressures, catering to the specific requirements of different applications. As industries continue to innovate and prioritize sustainability, the demand for these pumps is expected to rise, highlighting their crucial role in modern fluid management systems.

Understanding the Working Mechanism of Electric Diaphragm Pumps

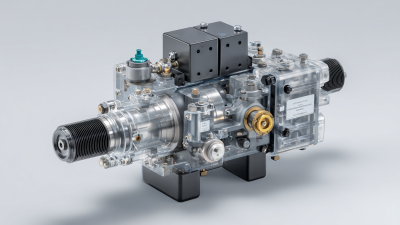

Electric diaphragm pumps are widely recognized for their efficiency in handling a variety of liquids, and understanding their working mechanism is crucial for optimal usage. These pumps operate through a diaphragm that flexes to create a vacuum, which allows the liquid to be drawn into the chamber. When the diaphragm moves back, the liquid is expelled through the outlet. This back-and-forth motion is typically powered by an electric motor, which ensures a steady and controlled flow, making electric diaphragm pumps suitable for sensitive applications.

When selecting an electric diaphragm pump, consider the viscosity of the liquid you’ll be pumping, as this affects the pump's performance. Additionally, check the pump's flow rate and pressure capabilities to ensure it meets your systems' requirements.

Tips: Regular maintenance is vital for ensuring the longevity of your diaphragm pump. Inspect the diaphragm and seals periodically for wear and tear, and replace them as necessary to prevent leaks. Lastly, using the appropriate fluid compatibilities will help maintain pump efficiency and prevent chemical damage.

Analysis of Key Benefits of Electric Diaphragm Pumps in Various Applications

Electric diaphragm pumps are increasingly recognized for their versatility and efficiency across various applications. One of their primary advantages is their ability to handle a wide range of liquids, including viscous and abrasive fluids, without the risk of contamination. This makes them particularly suitable for industries such as food and beverage, pharmaceuticals, and chemicals, where maintaining product purity is crucial. Additionally, these pumps can operate dry without damage, which significantly reduces the downtime often associated with pump failure.

Another key benefit of electric diaphragm pumps is their low maintenance requirements. Unlike traditional mechanical pumps, which may require frequent servicing due to wear and tear, diaphragm pumps are designed with fewer moving parts. This not only enhances their reliability but also minimizes operational costs. Furthermore, their compact design allows for installation in tight spaces, making them ideal for both new projects and retrofitting existing systems. With the capability to maintain precise flow rates and pressures, electric diaphragm pumps are an excellent choice for applications that demand consistent performance and efficiency.

Top 5 Electric Diaphragm Pumps: Key Features and Benefits Explained

| Pump Model | Key Features | Benefits | Typical Applications |

|---|---|---|---|

| Model A | Corrosion-resistant materials, Adjustable flow rate | Durability in harsh environments | Chemical processing |

| Model B | Low noise operation, Compact design | Ideal for indoor applications | Food and beverage |

| Model C | Self-priming, Quick maintenance access | Efficiency and reduced downtime | Wastewater treatment |

| Model D | High chemical compatibility, Versatile mounting options | Flexibility for different applications | Pharmaceuticals |

| Model E | Smart control features, Real-time monitoring | Enhanced safety and efficiency | Oil and gas |

Comparison of Performance Metrics: Flow Rates and Pressure Capabilities

When selecting an electric diaphragm pump, it's essential to consider performance metrics such as flow rates and pressure capabilities. Flow rate is a crucial factor, as it determines how quickly a pump can transfer fluids. High flow rates are advantageous for applications that require rapid fluid movement, while lower flow rates may suffice for more controlled environments. Many pumps can achieve varying flow rates depending on the application and the pump design, so understanding your specific needs is critical.

Pressure capabilities are equally important, as they influence the pump’s ability to handle different fluids and overcome system resistance. Higher pressure ratings allow pumps to operate effectively in tougher conditions and with thicker fluids. When comparing electric diaphragm pumps, examine the specifications carefully to ensure the pump can deliver the necessary pressure for your application, whether it's for gentle dispensing or high-pressure transfer.

Tips: Always refer to the manufacturer’s guidelines for the recommended applications and limitations of each model. Consider conducting a test run with your specific fluid to gauge the pump’s performance under real conditions. Additionally, keep in mind that regular maintenance can significantly enhance the longevity and efficiency of your diaphragm pump, regardless of its specifications.

Top 5 Electric Diaphragm Pumps: Flow Rates and Pressure Capabilities

Industry Insights: Market Trends and Innovations in Diaphragm Pump Technology

The diaphragm pump market is witnessing significant advancements driven by the growing demand for sustainable and efficient solutions across various industries. According to a recent report by Research and Markets, the global diaphragm pump market is projected to grow at a CAGR of 5.8% from 2023 to 2028, indicating a robust trend towards the adoption of electric diaphragm pumps. This growth is fueled by the increasing need for precise fluid handling in applications such as water treatment, pharmaceuticals, and food processing, where efficiency and hygiene are paramount.

Innovations in diaphragm pump technology focus on enhancing durability and operational efficiency while minimizing maintenance requirements. Key features include advanced materials that resist corrosion and wear, as well as improved sealing technologies that ensure leak-free operation. Industry experts note that the integration of smart technologies, such as IoT-enabled monitoring systems, provides real-time data for performance optimization and predictive maintenance, significantly reducing downtime and operational costs.

Tips: When selecting an electric diaphragm pump, consider factors like the fluid type and viscosity, operating temperature, and flow rate requirements. Additionally, investing in a pump with a robust warranty and customer support can provide peace of mind and safeguard your venture against unexpected challenges. Regular maintenance checks can also enhance the longevity and reliability of your pump system.

Related Posts

-

Understanding the Benefits of Electric Diaphragm Pumps in Modern Industrial Applications

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.