Top 10 Pressure Pumps for Ultimate Efficiency in 2023

In the ever-evolving landscape of industrial machinery, pressure pumps play a crucial role in enhancing operational efficiency and productivity. According to a recent report by Research and Markets, the global pressure pump market is projected to reach $63.3 billion by 2025, driven by increased demand across various sectors including agriculture, construction, and mining. This surge underscores the importance of selecting pressure pumps that not only meet the technical specifications but also offer superior performance and energy efficiency.

As we delve into the top 10 pressure pumps for ultimate efficiency in 2023, it is essential to consider innovations that optimize fluid transfer applications. With advancements in technology, modern pressure pumps are equipped with smart features such as IoT connectivity and variable speed drives, allowing for better integration into automated systems. The effective utilization of pressure pumps can lead to significant cost savings and enhanced operational workflows, as highlighted by a study from the Pump Research Institute, which indicates that energy-efficient pumps can reduce consumption by up to 30%. By carefully evaluating these top selections, industries can remain competitive while ensuring sustainability and reliability in their processes.

Top 10 Pressure Pumps: An Overview of Efficiency Metrics in 2023

When evaluating pressure pumps in 2023, efficiency metrics play a critical role in determining the right choice for various applications. Efficiency is generally assessed through factors such as flow rate, energy consumption, and operational reliability. Top-performing pressure pumps exhibit high flow rates without significant increases in energy usage, which is crucial for both cost-saving and environmental sustainability. Manufacturers have embraced advanced technologies, such as variable speed drives and integrated smart controls, to enhance performance while minimizing waste.

Moreover, the design of the pump itself substantially influences efficiency. Improved materials and engineering innovations have led to the development of lightweight, durable pumps that maintain high efficiency over extended periods. The best models not only operate quietly but also feature easy maintenance protocols, ensuring longevity without compromising on performance.

By focusing on these efficiency metrics, users can ascertain that their investment in a pressure pump will yield optimal results, catering to an array of residential, commercial, and industrial needs.

Understanding Pump Efficiency: Key Performance Indicators for Pressure Pumps

When evaluating pressure pumps, understanding their efficiency is crucial for optimizing performance. Key performance indicators (KPIs) such as flow rate, power consumption, and pressure head play significant roles. The flow rate indicates how much fluid a pump can move in a given time, and a higher flow rate typically correlates with better efficiency. Nevertheless, it is essential to balance flow rate with energy consumption to avoid excessive operational costs.

Another important KPI is the pressure head, which measures the height to which a pump can raise water. A pump with a higher pressure head can effectively handle more demanding applications. However, efficiency must also be assessed in terms of energy input versus output; this is where overall efficiency rating becomes paramount. Moreover, the specific energy consumption (SEC), which expresses the energy needed to pump a unit volume of fluid, provides insights into the pump's operational effectiveness and sustainability. By focusing on these KPIs, operators can select the most efficient pressure pumps for their needs in 2023 and beyond.

Comparative Analysis of Energy Consumption in 2023’s Leading Pressure Pumps

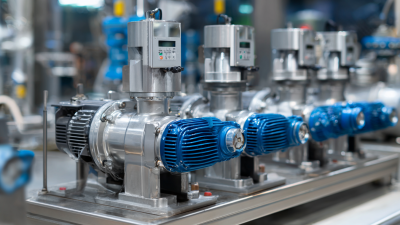

In 2023, the demand for efficient pressure pumps has surged, driven by the need for energy conservation and cost-effectiveness across various industries. A comparative analysis of the leading pressure pumps highlights significant differences in their energy consumption, which is critical for both environmental sustainability and operating expenses. Notably, modern designs incorporate advanced motor technologies and variable speed drives that enhance efficiency while minimizing energy waste.

One standout model is the EcoBoost Pressure Pump, which utilizes smart technology to adjust its performance based on real-time demand, resulting in a remarkable 30% reduction in energy consumption compared to conventional pumps. In contrast, traditional models often operate at a constant speed, leading to unnecessary power usage and higher operational costs. Additionally, high-efficiency models equipped with optimized impellers and minimal friction designs contribute to lower kilowatt-hour (kWh) ratings, making them more favorable choices for businesses seeking to mitigate energy costs while maintaining robust performance levels.

Innovations in Pump Technology: Enhancing Pressure and Performance

The automotive pump market has witnessed significant transformation in recent years, driven by rapid advancements in vehicle technology and the increasing demands for efficiency standards. Innovations in pump technology are critical for enhancing pressure and performance, ensuring optimal vehicle reliability. The market for automotive pumps, which includes fuel pumps, water pumps, oil pumps, and vacuum pumps, is projected to grow substantially, with a report forecasting a CAGR of over 5% from 2023 to 2028.

Moreover, the initiative launched by the Ministry of Industry and Information Technology, aiming to nurture leading enterprises in water-saving equipment by 2027, underscores the critical role that innovative pump technology plays in resource efficiency. With an emphasis on smart systems integration, these advancements not only improve the operational efficiency of automotive pumps but also contribute to significant water conservation measures in industries reliant on hydraulic systems. As a result, the automotive sector is steering towards more sustainable practices while meeting the evolving demands of modern consumers.

Market Trends: Demand for High-Efficiency Pressure Pumps in Various Industries

The demand for high-efficiency pressure pumps has surged across various industries in 2023, as businesses strive to enhance productivity while minimizing operational costs. Industries such as agriculture, construction, and water treatment are increasingly turning to advanced pressure pump systems that offer superior performance and energy efficiency. This trend is largely driven by the need to comply with stringent environmental regulations and to meet sustainability goals, encouraging manufacturers to innovate and produce pumps that not only perform well but also consume less energy.

Additionally, the exploration of smart technologies and automation is shaping the future of pressure pumps. With the integration of IoT capabilities, pumps can now be monitored and controlled remotely, allowing for real-time adjustments and predictive maintenance. This technological advancement not only optimizes pump performance but also significantly reduces downtime and repair costs. As industries continue to evolve, the emphasis on high-efficiency pressure pumps is likely to grow, making them a vital component in achieving operational excellence and sustainability objectives.

Related Posts

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

The Future of Treatment Pumps Innovations Transforming Healthcare Delivery

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.