5 Best Advantages of Diaphragm Pumps in Industrial Applications

In the realm of industrial applications, diaphragm pumps have emerged as a critical element due to their unique design and operational benefits. According to a report by MarketsandMarkets, the diaphragm pump market is projected to reach USD 4.4 billion by 2025, expanding at a CAGR of 5.8% from 2020. This growth is driven by their capability to handle abrasive and viscous fluids while ensuring efficient and reliable operation. Diaphragm pumps are particularly favored in industries such as chemical processing, wastewater treatment, and food & beverage, where precision and safety are paramount. By employing a diaphragm mechanism, these pumps not only minimize the risk of contamination but also provide superior performance in varying pressure conditions. As industrial operations continue to seek cost-effective and versatile pumping solutions, the advantages of diaphragm pumps reaffirm their vital role in enhancing productivity and operational reliability.

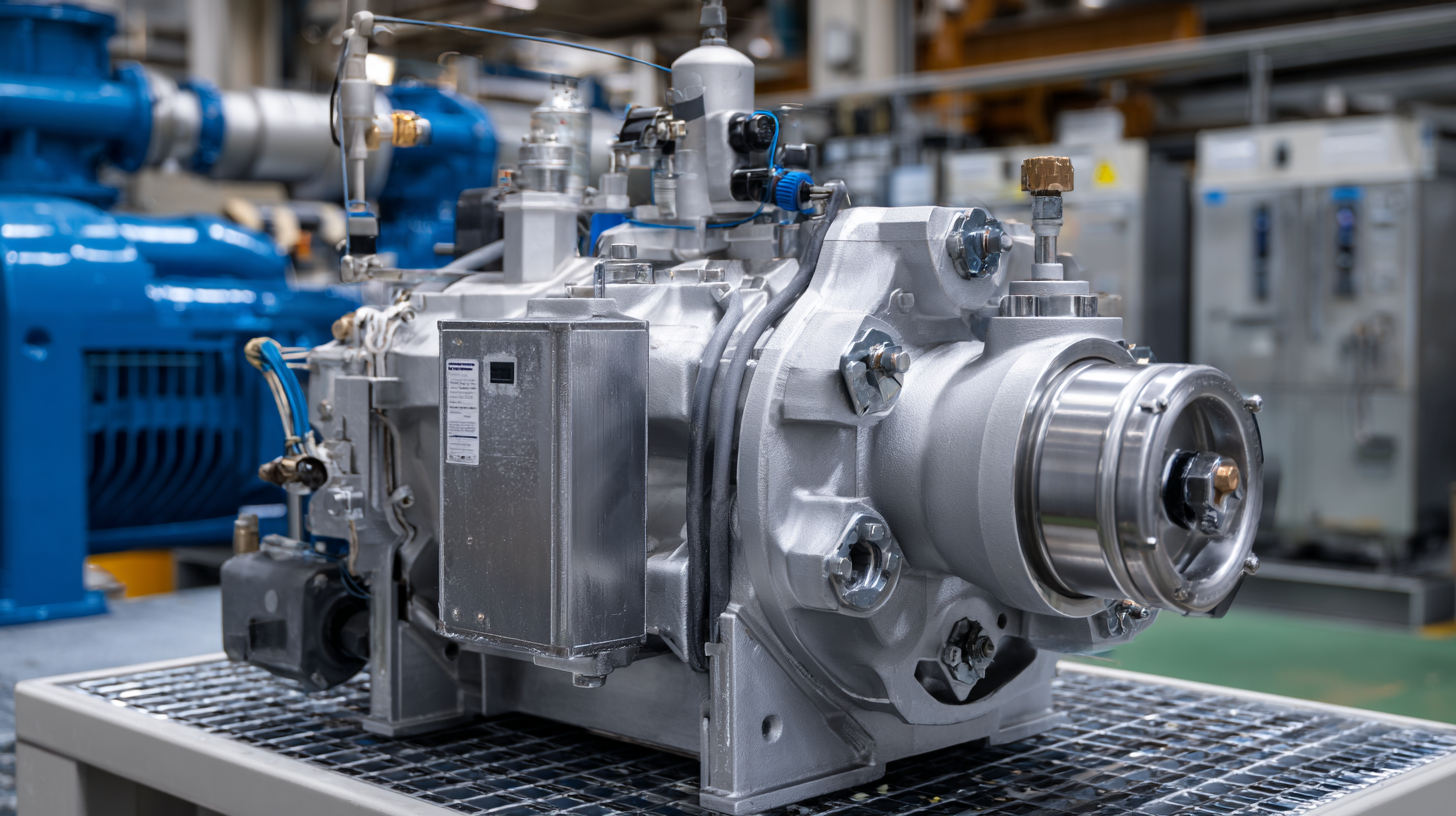

Understanding the Unique Mechanism of Diaphragm Pumps in Industry

Diaphragm pumps play a crucial role in various industrial applications, primarily due to their unique mechanism of operation which offers several advantages over traditional pumping methods. The Air-Operated Double Diaphragm (AODD) pumps, in particular, are recognized for their efficiency and reliability in handling a wide range of fluids, including those that are viscous, abrasive, or contaminated. Their ability to operate without electricity makes them particularly advantageous in hazardous environments where electric pumps may pose safety risks.

The diaphragm pump market is experiencing significant growth, with the global market size expected to increase from USD 6.27 billion in 2023 to nearly USD 9.97 billion by 2032. This growth reflects the increasing demand for high-performance and versatile pumping solutions across industries such as chemical processing, food and beverage, and wastewater treatment.

The unique mechanism of diaphragm pumps, involving the use of flexible membranes to create a pumping action, ensures minimal leakage and allows for precise fluid handling, which is essential in maintaining product quality and safety in industrial applications. As industries continue to seek more efficient and reliable solutions, diaphragm pumps are likely to remain at the forefront of fluid handling technology.

Enhanced Fluid Compatibility: The Versatility of Diaphragm Pump Materials

Diaphragm pumps have become increasingly popular in various industrial applications due to their enhanced fluid compatibility. The versatility of the materials used in diaphragm pumps allows them to handle a wide range of fluids, including corrosive chemicals, viscous liquids, and even shear-sensitive substances. This capability is crucial in industries such as chemical processing, pharmaceuticals, and food production, where the nature of the fluids requires pumps that can maintain integrity and performance under varying conditions.

One of the key advantages of diaphragm pump materials is their ability to resist chemical degradation. For instance, pumps made from PTFE (polytetrafluoroethylene) or other specialized elastomers can effectively manage harsh substances without deteriorating. This ensures not only longevity but also reliability in operations, mitigating the risks of leaks and contamination. Moreover, the diaphragm design itself minimizes the risk of fluid mixing, making these pumps ideal for applications requiring strict adherence to purity standards. The adaptability of diaphragm pumps to different fluids and environments solidifies their role as essential tools in modern industrial settings.

5 Best Advantages of Diaphragm Pumps in Industrial Applications - Enhanced Fluid Compatibility: The Versatility of Diaphragm Pump Materials

| Advantage | Description | Material Types | Typical Applications |

|---|---|---|---|

| Fluid Compatibility | Can handle a wide range of fluids including corrosive and viscous materials. | PTFE, EPDM, NBR | Chemical processing, food and beverage |

| Self-Priming | Can draw fluid without the need for additional priming equipment. | Polypropylene, Aluminum | Water treatment, waste management |

| Dry Run Capability | Can operate without fluid without damage, reducing downtime. | Stainless Steel, HDPE | Mining, agricultural chemicals |

| Low Shear Rate | Gentle pumping action preserves the integrity of shear-sensitive fluids. | Silicone, Hytrel | Pharmaceuticals, cosmetics |

| Versatility | Configurability for various flow rates and pressures. | Various plastics, metals | Industrial manufacturing, laboratories |

Low Maintenance Needs: Saving Time and Costs in Industrial Operations

Diaphragm pumps have emerged as a key player in industrial applications, particularly due to their low maintenance needs, which translate into significant savings in time and costs. According to a report by Research and Markets, globally, the diaphragm pump market is expected to grow at a CAGR of approximately 6% from 2021 to 2026, driven by the increasing focus on operational efficiency and cost reduction in various industries. The mechanism of diaphragm pumps minimizes wear and tear, leading to fewer breakdowns, which is particularly advantageous in sectors such as chemical processing and wastewater management.

Furthermore, the reduced maintenance requirements directly impact operational productivity. With conventional pumps often facing wear-related replacements every few months, diaphragm pumps can function effectively for years with minimal interventions. The Hydraulic Institute states that maintenance costs can constitute up to 30% of the total operating costs of industrial pumps, and by adopting diaphragm pumps, facilities can potentially reduce these expenses significantly. This efficiency is crucial for industries aiming to optimize their supply chains and enhance overall performance without sacrificing reliability, ensuring a smoother flow of operations.

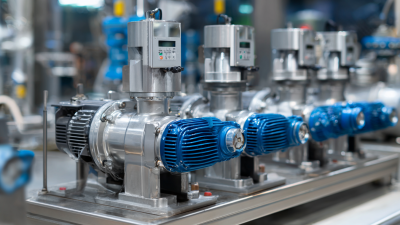

Self-Priming Capabilities: Simplifying Pumping Processes

Diaphragm pumps have gained significant traction in industrial applications, particularly due to their self-priming capabilities. This feature allows the pumps to draw fluid from below their level without needing external priming. According to a report from Global Market Insights, the diaphragm pump market is anticipated to reach USD 3 billion by 2026, largely driven by industries that require efficient, reliable pumping solutions. This self-priming attribute not only simplifies operations but also enhances productivity, reducing downtime associated with manual priming processes.

In addition to their self-priming advantages, diaphragm pumps can handle a wide range of fluid viscosities and are adept at managing abrasive and corrosive media. The versatility provided by self-priming capability makes these pumps an essential choice in sectors like chemical processing, wastewater treatment, and food and beverage manufacturing. Research from the Hydraulic Institute suggests that the ability to self-prime can reduce installation costs and complexities, enabling facilities to optimize their workflows while maintaining high standards of safety and efficiency. Consequently, diaphragm pumps are becoming an industry standard where reliability and ease of use are paramount.

Safe Handling of Hazardous Materials with Diaphragm Pumps

Diaphragm pumps are increasingly recognized for their essential role in the safe handling of hazardous materials across various industrial sectors. One of the significant advantages of diaphragm pumps is their ability to operate without the need for direct mechanical seals, which minimizes the risk of leaks and spills. According to a report by the American Society of Mechanical Engineers (ASME), spills resulting from leaking pumps can lead to environmental hazards and costly cleanup operations, potentially exceeding millions in expenses. Diaphragm pumps mitigate these risks by providing a sealed pumping mechanism, ensuring that harmful substances are contained efficiently throughout the process.

Moreover, diaphragm pumps are known for their versatility in handling a wide range of fluids, including corrosive chemicals and abrasive slurries. A study published by the Chemical Engineering Journal highlights that diaphragm pumps can handle fluid viscosities from 1 to over 1,000 centipoise, making them suitable for diverse applications, from wastewater treatment to the pharmaceutical industry. Their robust design also allows for the accommodation of solid particles, which is crucial when dealing with materials like paints and coatings that often contain abrasive components. By utilizing diaphragm pumps, industries can ensure compliance with safety regulations while enhancing operational efficiency, further solidifying their importance in the safe management of hazardous materials.

5 Best Advantages of Diaphragm Pumps in Industrial Applications

This chart illustrates the key advantages of diaphragm pumps in industrial applications, highlighting their effectiveness in safe handling of hazardous materials.

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

How to Choose the Right Electric Pump for Your Specific Needs

-

What is the Functionality Behind Liquid Pumps in Modern Industries

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.