Best Chemical Injection Pumps for Industrial Applications?

In the realm of industrial applications, choosing the right chemical injection pumps is crucial. According to Dr. Emily Carter, a renowned expert in fluid dynamics, "The right pump can significantly enhance operational efficiency." This statement encapsulates the importance of selecting suitable equipment in any chemical process.

Chemical injection pumps serve a vital role in industries such as water treatment and oil refining. They ensure precise chemical dosages, thus improving system performance. However, not all pumps are created equal. Each application has unique requirements, and failure to match the pump correctly can lead to inefficiencies.

In an industry where precision is paramount, understanding the nuances of chemical injection pumps is essential. Factors like flow rate, pressure, and material compatibility must be evaluated. Yet, many companies overlook these details, leading to costly operational downtime. Reflecting on past mistakes can drive better choices in pump selection and enhance productivity.

Types of Chemical Injection Pumps Used in Industrial Settings

Chemical injection pumps play a crucial role in various industrial applications. These pumps are essential for transporting chemicals efficiently and safely. They help maintain the desired chemical balance in processes. Several types of chemical injection pumps are widely used in these settings.

The most common type is the diaphragm pump. It uses a flexible diaphragm to create suction and displace liquids. This design allows for precise control of chemical flow rates. Another popular option is the gear pump. It relies on rotating gears to move fluids. This type can handle viscous chemicals effectively. Progressive cavity pumps are also significant, ideal for multiple types of fluids, including slurries.

When selecting a pump, consider the chemical properties. Corrosive substances may require special materials. It’s easy to overlook this detail. Operators must also think about the accuracy and control of the flow rates. Ensuring these factors can be challenging. Regular maintenance is required to prevent issues. Understanding the limitations of each pump type helps in making better choices. Not all setups are perfect, and adjustments may be necessary over time.

Best Chemical Injection Pumps for Industrial Applications

| Pump Type | Flow Rate (GPH) | Pressure Rating (PSI) | Material Compatibility | Control Type |

|---|---|---|---|---|

| Diaphragm Pump | 0.5 - 50 GPH | 100 - 1500 PSI | Acids, Bases, Solvents | Manual, Electric |

| Peristaltic Pump | 1 - 100 GPH | 80 - 200 PSI | Corrosive Fluids, Clean Liquids | Manual, Electric, Digital |

| Gear Pump | 5 - 200 GPH | 50 - 3000 PSI | Water, Oil, Chemicals | Electric, Pneumatic |

| Progressive Cavity Pump | 3 - 30 GPH | 100 - 800 PSI | Viscous Fluids, Slurries | Manual, Electric |

Key Features to Consider When Selecting a Chemical Injection Pump

Selecting the right chemical injection pump is crucial for efficient industrial operations. It requires careful consideration of key features. One important factor is the pump type. Different pumps have unique applications. Some are better for low-viscosity fluids, while others excel with thicker substances. Users must analyze their specific needs before making a decision.

Another aspect worth pondering is the pump's capacity. Understanding flow rate requirements can significantly affect operational efficiency. A pump that is too small can lead to under-delivery, which might disrupt processes. On the other hand, an oversized pump could waste resources and energy. Therefore, a proper assessment of needed output is essential.

Durability plays a pivotal role in pump selection. Industries often expose pumps to harsh conditions. Pumps must withstand varying temperatures and corrosive chemicals. Users should evaluate materials used in construction, ensuring they match the operational environment. Quality can sometimes be overlooked, leading to frequent replacements. This is an oversight that can affect productivity and costs over time.

Top Brands and Models of Chemical Injection Pumps in the Market

When selecting chemical injection pumps for industrial applications, various top models stand out. These pumps play a crucial role in efficiently delivering chemicals into processes. Fluids like acids, bases, or solvents require reliability. The right pump ensures safety and precision in operations.

Several brands offer innovative technology and durable designs. Positive displacement pumps are often favored for their consistent flow rates. These pumps can handle varying pressures. They are common in water treatment and oil industries. Some designs feature advanced control systems that enhance performance. Users should look for ease of maintenance; it contributes to lower operating costs.

However, not all models are without flaws. Some units may encounter issues like cavitation or leakage. These problems can disrupt production. It’s vital to regularly assess pump performance. Owners should maintain a proactive approach. Proper training for staff can mitigate risks and errors. Ultimately, investing in a quality chemical injection pump pays off in efficiency and safety.

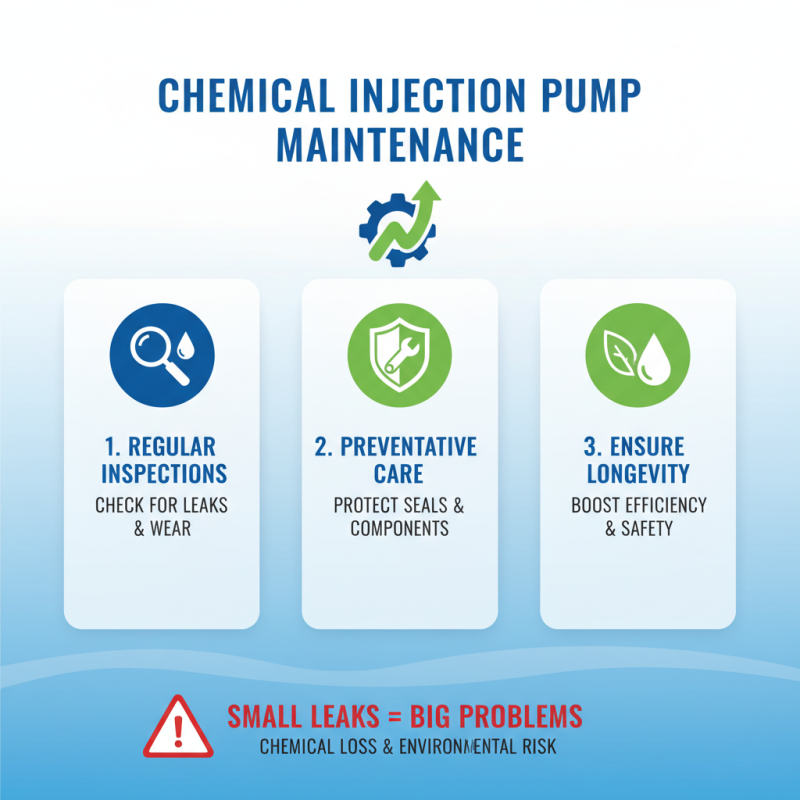

Maintenance and Troubleshooting Tips for Chemical Injection Pumps

When it comes to chemical injection pumps, proper maintenance is key to ensuring efficiency and longevity. Regular inspections for leaks and wear on seals can prevent significant issues down the line. A small leak can escalate quickly, causing chemical loss and potential environmental hazards.

Troubleshooting is often required when performance declines. Look out for unusual noises or inconsistent flow rates. These indicators shouldn't be ignored. Sometimes, simply checking the calibration can reveal overlooked problems. Ensure all monitoring equipment is functioning correctly to provide accurate feedback on pump performance.

Don't forget to keep a maintenance log. Documenting each service activity helps identify patterns and recurring issues. Reflecting on these logs can aid in making informed decisions for future maintenance schedules. It can be frustrating when things go wrong, but being proactive is essential. Regular attention can save time and avoid costly downtimes.

Applications and Industries Utilizing Chemical Injection Pumps Efficiently

Chemical injection pumps are widely used in various industries to manage vital processes. These pumps ensure precise dosing of chemicals, which is crucial in sectors like water treatment and oil and gas. According to a recent market report, the global chemical injection pump market is projected to grow by 5.2% annually. This growth reflects the rising demand for enhanced efficiency in chemical handling.

In water treatment facilities, chemical injection pumps inject coagulants and disinfectants. These substances help maintain water quality and prevent contamination. A study found that optimizing chemical dosing can reduce costs by up to 15%. However, improper pump selection can lead to inefficiencies. Pumps that are not suited for specific chemicals can malfunction, leading to waste.

The oil and gas industry also utilizes these pumps for various applications, including enhanced oil recovery. A report indicated that nearly 30% of oil production facilities employ chemical injection systems. Yet, challenges remain. Many systems face issues with wear and tear, affecting reliability. Regular maintenance is essential to minimize downtime and ensure consistent performance.

Best Chemical Injection Pumps for Industrial Applications

Related Posts

-

Understanding the Role of Chemical Pumps in Enhancing Water Treatment Efficiency

-

Maximizing Efficiency: The Role of Chemical Injection Pumps in Reducing Operational Costs by 20% in the Oil Industry

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

2025 Top Chemical Injection Pumps: The Ultimate Guide to Choosing the Best Options

-

Why Chemical Pumps Are Essential for Efficient Water Treatment Solutions

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.