How to Choose the Right Electric Pumps for Your Business Needs

In today's rapidly evolving industrial landscape, selecting the appropriate electric pumps for your business needs has become a critical decision that can significantly impact operational efficiency and cost-effectiveness. According to a report by Research and Markets, the global electric pump market is expected to grow from $49.87 billion in 2020 to $66.10 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.05%. This surge is driven by advancements in pump technology and increasing demand across various sectors, including water and wastewater management, agriculture, and oil and gas. As businesses strive to optimize their processes and reduce energy consumption, understanding the diverse range of electric pumps available and their specific applications is essential. This guide aims to equip you with the necessary insights to make informed decisions, ensuring you select the electric pumps that best meet your operational requirements.

Understanding the Different Types of Electric Pumps and Their Applications

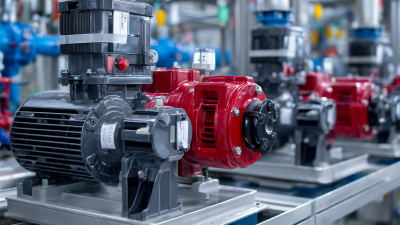

When selecting electric pumps for your business, it's essential to understand the various types available and their specific applications. Electric pumps are broadly classified into two main categories: Centrifugal Pumps and Positive Displacement Pumps.

Centrifugal pumps are ideal for moving large volumes of fluids at low pressures, making them suitable for applications like water supply and irrigation systems. They operate by converting rotational energy into fluid movement, ensuring efficiency in handling non-viscous fluids.

On the other hand, Positive Displacement Pumps excel in scenarios where precise flow rates and higher pressures are required.

These pumps work by trapping a fixed amount of fluid and then forcing it out, which is particularly beneficial for transferring viscous fluids, such as oils or slurries. Choosing the right type depends greatly on the specific needs of your business, including the fluid characteristics and required flow rate. By evaluating these factors and understanding the applications of each pump type, you can make an informed decision that enhances operational efficiency.

Key Factors Influencing Electric Pump Selection for Businesses

When selecting electric pumps for your business, several key factors come into play that can significantly influence your choice. Firstly, understanding the specific application requirements is crucial. According to a report by the Hydraulic Institute, approximately 80% of electric pump inefficiencies are attributable to mismatched operational conditions. Therefore, assessing parameters such as flow rate, pressure, and the liquid properties (viscosity, temperature, and chemical compatibility) is vital for optimal performance.

Another critical aspect involves evaluating the pump's energy efficiency. The U.S. Department of Energy states that pumps can account for nearly 20% of a facility's energy consumption. Choosing pumps with energy-efficient motors can not only reduce operating costs but also align with sustainability initiatives. Look for pumps that meet the latest efficiency standards and consider advanced technologies like variable frequency drives (VFDs), which can optimize energy use and reduce wear on pump components, extending their lifespan and decreasing maintenance costs.

Lastly, considering the total cost of ownership (TCO) is essential. A study by the American Society of Mechanical Engineers (ASME) highlights that initial purchase cost often pales in comparison to operational and maintenance costs over a pump's lifetime. For businesses, a thorough analysis of TCO will facilitate smarter investment decisions and long-term savings, ensuring that the selected electric pumps meet both current and future business needs effectively.

Electric Pumps Selection Criteria

Industry Growth Trends Impacting Electric Pump Demand and Innovations

The electric pump industry is witnessing significant growth driven by evolving market demands and technological innovations. As industries increasingly prioritize efficiency and sustainability, the need for high-performance electric pumps has surged. For instance, sectors such as agriculture and wastewater management are embracing electric pumps for their ability to minimize operational costs while maximizing performance. The push towards greener solutions is steering investments in electric pump technologies that reduce energy consumption and environmental impact.

Moreover, recent innovations in smart pumping systems are reshaping the landscape. By integrating IoT and automation, businesses can now monitor and control pump operations remotely, enhancing efficiency and reducing downtime. These advancements not only streamline maintenance schedules but also provide real-time data analytics, enabling companies to make informed decisions on pump selection based on their specific operational needs. As market dynamics continue to evolve, understanding these trends will be crucial for businesses looking to adopt the most suitable electric pumps for their applications.

Comparative Analysis of Electric Pump Efficiency and Energy Consumption

When selecting electric pumps for your business, it's crucial to consider their efficiency and energy consumption. Recent studies indicate that electric pumps can vary significantly in their energy usage, with some models consuming up to 30% more power than others for the same output. For instance, a report from the U.S. Department of Energy highlights that more efficient pumps, such as those with variable frequency drives (VFDs), can reduce energy consumption by as much as 50% compared to traditional fixed-speed pumps.

Furthermore, the efficiency of electric pumps is often expressed in terms of their hydraulic efficiency, which measures how effectively a pump converts electrical energy into hydraulic energy. According to the Hydraulic Institute’s recent findings, the average hydraulic efficiency of domestic pumps stands at around 60-70%. However, advanced models can achieve efficiencies exceeding 85%, which not only lowers operational costs but also contributes to a smaller environmental footprint. By choosing pumps with higher energy efficiency ratings, businesses can further optimize their energy consumption, leading to significant long-term savings and sustainability benefits.

How to Choose the Right Electric Pumps for Your Business Needs - Comparative Analysis of Electric Pump Efficiency and Energy Consumption

| Pump Type | Max Flow Rate (GPM) | Power Consumption (kW) | Efficiency (%) | Operating Cost ($/hour) |

|---|---|---|---|---|

| Submersible Pump | 25 | 4.5 | 85 | 0.40 |

| Centrifugal Pump | 45 | 6.0 | 80 | 0.54 |

| Diaphragm Pump | 30 | 3.0 | 75 | 0.27 |

| Positive Displacement Pump | 20 | 5.0 | 82 | 0.45 |

Case Studies: Successful Implementation of Electric Pumps in Various Industries

Electric pumps play a vital role in various industries, enhancing operational efficiency and sustainability. For instance, in the agricultural sector, a report by the International Water Management Institute highlights that implementing electric pumps can increase irrigation efficiency by up to 30%. This not only optimizes water usage but also boosts crop yields significantly, providing a clear advantage for farmers who adopt such technology. One case study from a leading agricultural cooperative demonstrated a 20% reduction in energy costs through the use of electric pumps, allowing farmers to reinvest their savings into other critical areas.

In the manufacturing sector, electric pumps have been instrumental in streamlining processes. According to the Chemical Engineering Journal, companies that switched from diesel to electric pumps reported a 15% improvement in production speed and a 25% decrease in maintenance expenses. A notable case involved a chemical manufacturer that implemented electric pumps in their operations, resulting in not only cost savings but also a reduction in greenhouse gas emissions by 40%. Such successful implementations underline the importance of selecting the right electric pump, tailored to the specific needs of the industry, ensuring both economic and environmental benefits.

Related Posts

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

What is the Functionality Behind Liquid Pumps in Modern Industries

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

Understanding the Different Types of Motor Pumps and Their Applications in Various Industries

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.