How to Choose the Best Pump Solutions for Your Needs?

In the dynamic world of pump solutions, choosing the right system is essential for efficiency and performance. According to John Mitchell, a renowned expert in the pump industry, “Selecting the right pump can save time, energy, and resources.” This statement emphasizes the critical role of thoughtful decision-making when it comes to pump solutions.

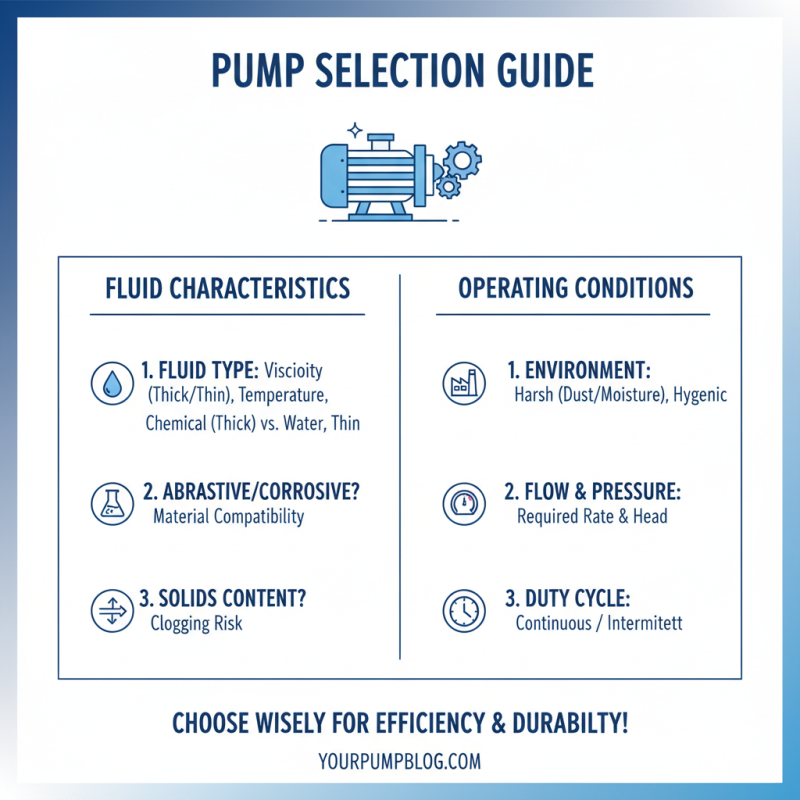

Identifying your specific needs is the first step. Different applications demand different pump types. Whether it's for water transfer, chemical handling, or industrial processes, the nuances matter. You should consider factors like flow rate, viscosity, and pressure requirements. This is where expertise can guide you. Rushing into a choice might lead to inefficiencies.

Another consideration is the long-term implications. The initial cost may not reflect the complete picture. Maintenance, energy consumption, and durability must also be weighed. Reflecting on the sustainability of your choices can lead to better overall results. Remember, in the realm of pump solutions, a well-informed decision today will serve you well tomorrow.

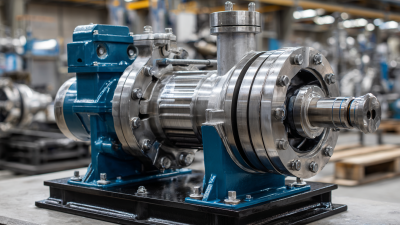

Understanding Different Types of Pumps Available in the Market

When selecting a pump, understanding the various types available is essential. There are centrifugal pumps, positive displacement pumps, submersible pumps, and diaphragm pumps. Each type serves specific applications and has unique benefits. Centrifugal pumps are great for moving large volumes of liquid quickly. They are often used in water supply and irrigation systems. However, they may not be efficient for thick fluids.

Positive displacement pumps, on the other hand, are better for high-viscosity fluids. They move a fixed amount of liquid with each cycle. It’s crucial to consider the nature of the fluid you’re handling. Submersible pumps are ideal for situations where the pump needs to be submerged in the liquid. They work efficiently in wells and sewage systems. But, installation can be challenging, requiring careful planning.

Tips: Always evaluate your fluid characteristics first. Understanding viscosity and temperature can save you money. Don’t forget to account for the pump's power source, as it affects performance. Consider the installation space. A poorly chosen pump may lead to inefficiency and higher costs. Remember, it’s okay to revisit your choice after some use. Pumps can often underperform or break. Reflecting on your needs is the key to long-term satisfaction.

How to Choose the Best Pump Solutions for Your Needs? - Understanding Different Types of Pumps Available in the Market

| Pump Type | Application | Fluid Type | Flow Rate (GPM) | Max Pressure (PSI) |

|---|---|---|---|---|

| Centrifugal Pump | Water Supply | Water | 10 - 100 | 50 - 150 |

| Positive Displacement Pump | Chemical Transfer | Viscous Fluids | 5 - 75 | 30 - 100 |

| Submersible Pump | Drainage | Sewage | 20 - 300 | 20 - 50 |

| Diaphragm Pump | Filling and Seeding | Chemicals, Slurries | 1 - 50 | 10 - 80 |

| Gear Pump | Oil Transfer | Oils | 5 - 100 | 50 - 300 |

Evaluating Your Specific Pumping Requirements and Applications

When evaluating your specific pumping needs, start by identifying the fluid to be pumped. The viscosity, temperature, and chemical composition of the fluid can greatly influence your choices. For example, thick fluids like sludge require different pumps compared to thin liquids like water. Consider the environmental conditions as well. In harsh settings, durability becomes essential.

Next, think about your desired flow rate. Do you need a constant flow or variable rates? This will help narrow your options. Some applications might require precise control, adding another layer of complexity. Also, think about installation space. Compact designs might be necessary for tight locations.

It’s easy to get lost in specifications and features. Sometimes, the optimal pump for your situation may not be the most advanced one. Reflect on the simplicity of your requirements. Too many features can complicate maintenance and operation. Balancing complexity with practicality can save you headaches down the line. Ask yourself if all those advanced options truly serve your needs.

Comparing Performance Factors: Flow Rate, Pressure, and Efficiency

When choosing pump solutions, understanding performance factors is essential. Flow rate, pressure, and efficiency are key metrics. A pump’s flow rate defines how much fluid it can move in a specific timeframe. Industrial standards often measure flow rates in gallons per minute (GPM) or liters per minute (LPM). Data from the Fluid Power Journal suggests that systems with higher flow rates improve productivity but may require more energy.

Pressure is another critical factor. It determines how effectively a pump can push fluid through a system. Higher pressure typically means better performance in challenging conditions. According to the Hydraulic Institute, pressure ratings should align with system requirements. A mismatch can lead to operational issues and increased wear.

Efficiency cannot be overlooked. It indicates how well a pump converts input energy into hydraulic energy. The U.S. Department of Energy found that a 10% improvement in pump efficiency can save significant energy costs over time.

**Tips:** Always check manufacturer specifications. Measure your system’s actual needs carefully. Assess long-term costs, not just initial prices. Regular maintenance can boost efficiency and prolong pump life. An imperfect understanding of these factors may lead to costly mistakes. Always reflect on your specific applications.

Analyzing Cost vs. Quality: Budgeting for Pump Solutions

When selecting pump solutions, cost versus quality becomes a pivotal point of analysis. Recent studies indicate that 70% of organizations prioritize initial costs when purchasing equipment, often overlooking the long-term implications. Cheaper pumps may seem appealing, but they often lead to increased maintenance expenses. This can negate any initial savings, leading to higher overall costs.

Additionally, high-quality pumps are generally more energy-efficient. According to a report from the Energy Efficiency Alliance, better-quality pumps can save around 20% to 50% on energy costs over their lifespan. This difference can significantly impact a budget, especially for industries relying on continuous operations. However, investing in quality upfront is a challenge. Many decision-makers struggle to justify this expense, sometimes opting for lower-tier solutions that require frequent repairs.

Ultimately, finding the right balance between cost and quality is crucial for sustainable operations. Organizations may reflect on their past choices — did a lower initial cost lead to unexpected costs? Smart budgeting considers both immediate and future needs. Though saving money is important, quality shouldn't be sacrificed.

Analyzing Cost vs. Quality for Pump Solutions

Identifying Reliable Manufacturers and Service Providers for Pumps

When choosing pump solutions, identifying reliable manufacturers and service providers is crucial. Look for companies with a solid track record. Research online reviews and ratings. Consider customer feedback as a key factor. A seasoned provider is likely to offer better support and solutions.

Contact potential suppliers for more information. Ask them about their experience in the industry. Understand their warranty policies. Check if they provide installation and maintenance services. Sometimes, manufacturers may overpromise. Don't hesitate to ask tough questions. This can help reveal their true capabilities.

In addition, evaluate their response times. Quick responses are a good sign of reliability. Ensure they have a dedicated customer service team. It’s also wise to visit their facilities, if possible. Observing their operations can provide insights. Remember, invested time in research now can save headaches later. The right choice begins with knowing who to trust.

Related Posts

-

Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

-

Top 10 Pump Solutions Tips You Need for Efficient Performance

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

What Makes a Plunger Pump Different from Other Pump Types

-

Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

-

Best Chemical Injection Pumps for Industrial Applications?

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.