How to Choose the Right Electric Pump for Your Specific Needs

Choosing the right electric pump for your specific needs is a crucial decision that can significantly impact

efficiency, cost-effectiveness, and overall performance in various applications. According to a market research report by Grand View Research,

the global electric pump market is expected to reach USD 64.56 billion by 2025, driven by the growing demand for energy-efficient systems across multiple

industries, including agriculture, water and waste management, and industrial applications.

The right electric pump not only enhances operational efficiency but also contributes to sustainability goals by

reducing energy consumption and operational costs. With the diverse range of electric pumps available, understanding the specific requirements of your application—such as flow rate, power, and durability—is essential for making an informed choice.

This guide aims to simplify the selection process by providing key insights into how to choose the ideal electric pump tailored to your unique operational needs.

The right electric pump not only enhances operational efficiency but also contributes to sustainability goals by

reducing energy consumption and operational costs. With the diverse range of electric pumps available, understanding the specific requirements of your application—such as flow rate, power, and durability—is essential for making an informed choice.

This guide aims to simplify the selection process by providing key insights into how to choose the ideal electric pump tailored to your unique operational needs.

Understanding Your Pumping Requirements: Assessing Flow Rate and Pressure Needs

When selecting the right electric pump, understanding your specific pumping requirements is crucial. An essential factor to consider is the flow rate, which measures how much fluid the pump can move in a given time, typically expressed in gallons per minute (GPM). According to the Hydraulic Institute, a proper flow rate is vital; over 25% of businesses with pumping needs report inefficiencies due to inappropriate pump sizing. Assessing your application’s flow requirements against available pump specifications will ensure optimal performance and energy efficiency.

Pressure needs are equally significant in the selection process. Measured in pounds per square inch (PSI), the pressure requirement will determine the pump type and design necessary for your application. A study by the American Society of Mechanical Engineers revealed that inadequate pressure management can lead to equipment failures, affecting operational productivity. It’s essential to thoroughly evaluate whether a centrifugal or positive displacement pump is suitable for your needs based on the required pressure range.

**Tips:** Always consider a safety margin in both flow rate and pressure to accommodate unforeseen variations in demand. Additionally, consult manufacturer datasheets and industry reports to obtain performance curves that help visualize how different pumps will perform under various conditions. This data is invaluable for making an informed choice that aligns with both short-term and long-term operational goals.

How to Choose the Right Electric Pump for Your Specific Needs - Understanding Your Pumping Requirements: Assessing Flow Rate and Pressure Needs

| Pump Type | Flow Rate (GPM) | Pressure (PSI) | Power Source | Application |

|---|---|---|---|---|

| Submersible Pump | 30 | 25 | Electric | Water Removal |

| Centrifugal Pump | 50 | 40 | Electric | Irrigation |

| Diaphragm Pump | 20 | 60 | Pneumatic | Chemical Transfer |

| Gear Pump | 15 | 80 | Electric | Fuel Transfer |

| Rotary Vane Pump | 25 | 75 | Electric | Vacuum Applications |

Types of Electric Pumps: Differences Between Submersible, Surface, and Diaphragm Pumps

When selecting the right electric pump, understanding the types available is critical. Submersible pumps are ideal for transferring water from deep wells or flooded areas as they are designed to operate underwater. Their sealed design makes them efficient and less susceptible to damage from environmental factors. According to a report by the International Water Association, submersible pumps account for approximately 30% of the global pump market due to their versatility in various applications, from agricultural irrigation to municipal water supply.

In contrast, surface pumps function above the fluid they are pumping, making them suited for applications where the water source is accessible. Typically used for irrigation and draining, surface pumps are easier to maintain due to their orientation. The Global Market Insights report indicates that the surface pump segment is projected to achieve significant growth, driven by increasing agricultural activities and advancements in technology. Lastly, diaphragm pumps, known for their ability to handle viscous fluids and slurries, offer reliability in industries ranging from food processing to pharmaceuticals. Their unique design allows for excellent containment and minimal leakage, making them a preferred choice for sensitive applications.

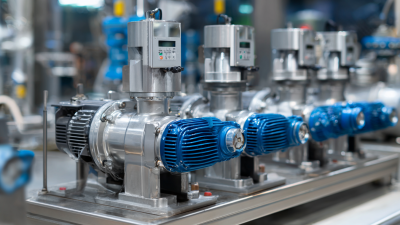

Evaluating Power Sources: Choosing Between Electric, Battery, and Solar-Powered Pumps

When selecting the right electric pump, one of the most critical decisions entails choosing the appropriate power source. A recent report by the U.S. Department of Energy (DOE) indicates that electric pumps account for approximately 20% of energy consumption in the pumping sector. Understanding the differences between electric, battery, and solar-powered pumps can greatly enhance efficiency and cost-effectiveness for specific applications.

Electric-powered pumps are renowned for their reliability and high efficiency. They are typically used in industrial and residential settings where the power supply is consistent. However, for remote locations without access to electrical lines, battery-powered pumps serve as a practical alternative. A study from the American Society of Mechanical Engineers (ASME) shows that while battery pumps offer mobility and ease of use, they may require frequent recharging and have limitations in runtime, especially for demanding tasks.

Solar-powered pumps present an innovative eco-friendly solution, capitalizing on renewable energy. According to a report by the International Renewable Energy Agency (IRENA), the adoption of solar-powered pumps has surged by over 35% in recent years due to decreasing costs of solar technology. These pumps are ideal for agricultural applications in remote locations where electricity is unavailable, providing a sustainable solution while minimizing operational costs. Careful evaluation of these power sources, based on individual needs and operational environments, is essential for optimal performance and efficiency.

Key Features to Consider: Size, Portability, and Durability of Electric Pumps

When selecting an electric pump, three critical features come into play: size, portability, and durability. According to a recent industry report by Grand View Research, the global electric pump market is expected to reach $66.77 billion by 2025, driven in part by the growing demand for pumps that can fit various operational spaces. A compact and appropriately sized pump ensures that it can efficiently handle the required flow rate without occupying excessive space, making it ideal for both residential and commercial applications.

Portability is another essential aspect, especially for users who require pumps for multiple locations or remote areas. A survey by the Pump Industry Institute revealed that 58% of users prioritize weight and ease of transport when choosing a pump. Electric pumps designed for portability often feature lightweight materials, integrated handles, and mobility-enhancing designs. Lastly, durability cannot be overlooked, as pumps are often exposed to challenging environments. A report from Transparency Market Research indicates that pumps with corrosion-resistant materials and robust construction have a longer lifespan, reducing maintenance costs and downtime. Prioritizing these features will help you find an electric pump that meets your specific needs effectively.

Electric Pump Comparison: Key Features

Budgeting for Your Pump: Balancing Initial Costs with Long-Term Maintenance Expenses

When selecting an electric pump, it's essential to consider not only the initial purchase price but also the long-term maintenance expenses. Often, a higher upfront cost can result in savings over time if the pump is more efficient and reliable. Cheaper models may seem appealing, but they often lead to frequent repairs and increased energy consumption, ultimately inflating your costs.

Tips: Always research the pump’s energy efficiency ratings. Investing in a model with a high-efficiency rating can significantly lower your electricity bills. Furthermore, check user reviews and the reputation of the manufacturer regarding reliability and support. A pump that requires less maintenance will reduce the need for spare parts and service over time.

Additionally, budgeting for maintenance is crucial. Factors such as the pump's environment, the frequency of use, and annual service requirements can all impact long-term costs. Understand your specific use case and consult with professionals if necessary to ensure your selection aligns with your needs.

Tips: Consider purchasing a warranty plan that covers common repairs, which can provide peace of mind and safeguard against unexpected expenses. Investing in preventive maintenance can also help extend the pump’s lifespan and reduce overall costs.

Related Posts

-

How to Choose the Right Electric Pumps for Your Business Needs

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

Evaluating Cost-Effectiveness: A Comparative Analysis of Pump Rentals vs. Purchasing Equipment

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.