How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

In today's industrial landscape, the efficiency and reliability of fluid transfer systems are paramount, making the selection of the right pressure pumps crucial for maximizing operational performance. According to a recent market analysis by Global Market Insights, the global pressure pump market is projected to reach $17 billion by 2026, growing at a compound annual growth rate (CAGR) of over 6%. This growth underscores the increasing importance of these pumps across various sectors, including oil and gas, water treatment, and manufacturing. Choosing the appropriate pressure pumps can significantly enhance energy efficiency, reduce operational costs, and ensure consistent fluid delivery, ultimately impacting a company's bottom line. With diverse types of pressure pumps available, understanding their specific functionalities and applications is essential for optimizing their performance in existing systems.

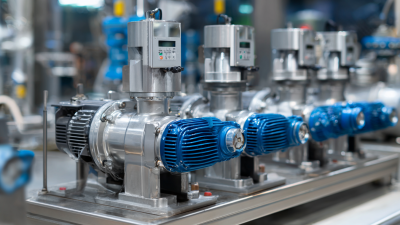

Understanding Different Types of Pressure Pumps and Their Applications

When selecting the right pressure pump for your specific applications, understanding the various types of pumps available is crucial. Pressure pumps can generally be categorized into several types, including positive displacement pumps, centrifugal pumps, and peristaltic pumps, each designed for unique operational demands. For instance, a report by the American Society of Mechanical Engineers (ASME) indicates that positive displacement pumps excel in scenarios requiring high pressure and low flow rates, making them ideal for applications like hydraulic systems or chemical processing where precise fluid handling is key.

On the other hand, centrifugal pumps are widely used in applications involving large volumes of fluids at lower pressures. According to the Hydraulic Institute, these pumps account for around 80% of the industrial pumps sold globally due to their efficiency in moving water, wastewater, and various chemicals. Furthermore, peristaltic pumps offer significant advantages in applications that require sterile fluid transfer, such as in the pharmaceutical industry, with recent studies suggesting that their ability to prevent contamination can enhance product safety by up to 95%.

Understanding your application requirements, coupled with insights from industry reports, can help guide you toward the most efficient pump choice for your needs.

Key Factors to Consider When Selecting Pressure Pumps for Efficiency

When selecting pressure pumps for maximum efficiency in various applications, several key factors must be considered. First, the required flow rate and pressure range significantly impact pump performance. According to a 2022 report by the Hydraulic Institute, selecting a pump that operates within 70-80% of its Best Efficiency Point (BEP) can lead to energy savings of up to 30%. This ensures the pump runs more efficiently with less risk of cavitation or overheating.

Moreover, compatibility with the fluid being pumped is crucial. Fluids differ in viscosity, temperature, and corrosiveness, and selecting a pump material that withstands these properties can prevent failures and maintenance costs. For instance, a study from the American Society of Mechanical Engineers (ASME) highlights that incorrect material choice can increase downtime by 40%, emphasizing the importance of thorough application analysis.

**Tips:** Always evaluate energy consumption ratings of potential pumps; opting for energy-efficient models can lead to significant cost reductions over time. Additionally, consider integrating variable frequency drives (VFDs) with your pump system to optimize performance dynamically based on demand, which can enhance overall system efficiency by 20-50%. Keep in mind that regular maintenance checks can also help maintain optimal performance and longevity.

Pressure Pumps Efficiency Comparison

Evaluating Performance Metrics: Flow Rate, Pressure, and Energy Consumption

When selecting pressure pumps for maximum efficiency, it's essential to evaluate key performance metrics such as flow rate, pressure, and energy consumption. The flow rate, measured in liters per minute, dictates the capacity of the pump to deliver water or other fluids. For instance, pumps with higher flow rates are critical in applications involving large-scale industrial processes, where delays can lead to substantial productivity losses.

According to industry reports, optimizing flow rates in systems like air gap membrane distillation can enhance overall performance, particularly when integrating heat recovery configurations that significantly reduce operational costs.

According to industry reports, optimizing flow rates in systems like air gap membrane distillation can enhance overall performance, particularly when integrating heat recovery configurations that significantly reduce operational costs.

Pressure is another crucial factor; it directly influences the effectiveness of the pump in delivering fluids against system resistance. High-pressure pumps are essential in applications such as brackish water desalination, where maintaining optimal pressure conditions can improve water recovery rates while minimizing energy consumption.

Recent studies indicate that integrated desalination processes utilizing advanced energy-efficient technologies can reduce energy usage by up to 30%. Furthermore, energy consumption should not be overlooked. Selecting pumps that achieve energy efficiency standards not only reduces operational costs but also aligns with sustainable practices outlined in performance evaluations for water utilities and HVAC systems. By conducting a thorough analysis of these metrics, organizations can ensure they choose the right pressure pumps for their specific applications, potentially improving both efficiency and environmental impact.

Maintenance Tips for Enhancing the Longevity and Efficiency of Pressure Pumps

When it comes to pressure pumps, regular maintenance is key to ensuring not only their longevity but also their efficiency. One essential tip is to schedule routine inspections. Checking for wear and tear, leaks, and unusual vibrations can help identify issues before they escalate. Additionally, maintaining proper fluid levels and ensuring the system is free from contaminants will keep your pump operating smoothly.

Another vital aspect of pump maintenance is implementing predictive technologies. Utilizing sensors and IoT technology can transform your maintenance approach from reactive to proactive. These advancements allow for real-time monitoring of pressure and flow rates, providing insights that help in early detection of potential failures. Such measures facilitate timely interventions, reducing downtime and maintenance costs.

Lastly, ensure that your pumps are appropriately chosen for the specific application. Using pressure pumps optimized for your operational needs, such as those designed for mining or dairy production, can greatly enhance performance. When your equipment is tailored to its task, not only will it run more efficiently, but you'll also extend the lifespan of your investment.

Common Mistakes to Avoid When Choosing Pressure Pumps for Your Needs

Choosing the right pressure pump can greatly enhance efficiency in various applications, but many make critical mistakes in the selection process. One common pitfall is failing to accurately assess the required flow rate and pressure. Without understanding the specific demands of your application, you risk selecting a pump that either underperforms or operates inefficiently, leading to increased energy costs and potential damage to the system.

**Tip:** Always conduct a thorough analysis of your system requirements before making a decision. Measure the necessary flow rate and pressure, as well as consider factors like viscosity and temperature of the fluid being pumped.

Another frequent error is ignoring the compatibility of materials. Not all pumps are suitable for every type of fluid, and choosing a pump made from incompatible materials can lead to premature wear or failure. This not only affects efficiency but could also lead to costly repairs or replacements.

**Tip:** Check the materials of construction for both the pump and the components within your system. Ensure that they are compatible with the fluids and conditions in your specific application to maximize longevity and efficiency.

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications - Common Mistakes to Avoid When Choosing Pressure Pumps for Your Needs

| Application | Pump Type | Flow Rate (GPM) | Pressure (PSI) | Efficiency Rating |

|---|---|---|---|---|

| Irrigation | Centrifugal | 20 | 40 | 85% |

| Industrial Cleaning | Positive Displacement | 15 | 300 | 90% |

| Water Transfer | Submersible | 30 | 50 | 80% |

| Aquarium | Inline | 10 | 20 | 75% |

| Heating Systems | Gear Pump | 25 | 60 | 88% |

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

Evaluating Cost-Effectiveness: A Comparative Analysis of Pump Rentals vs. Purchasing Equipment

-

What is the Functionality Behind Liquid Pumps in Modern Industries

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.