Addressing Common Issues with Top Vacuum Pump Components for Optimal Performance

In today's industrial landscape, the efficiency and reliability of vacuum systems are paramount for optimal performance across various applications, from semiconductor manufacturing to pharmaceuticals. According to a recent market report by Grand View Research, the global vacuum pump market is projected to reach $4.18 billion by 2028, driven by increasing demand for vacuum pump parts that enhance system performance and durability. However, despite technological advancements, common issues with vacuum pump components persist, potentially compromising operational efficiency. This blog explores these prevalent challenges and provides insights into best practices for maintaining vacuum pump parts, ensuring that businesses can maximize their investment and maintain the high standards required in critical manufacturing processes.

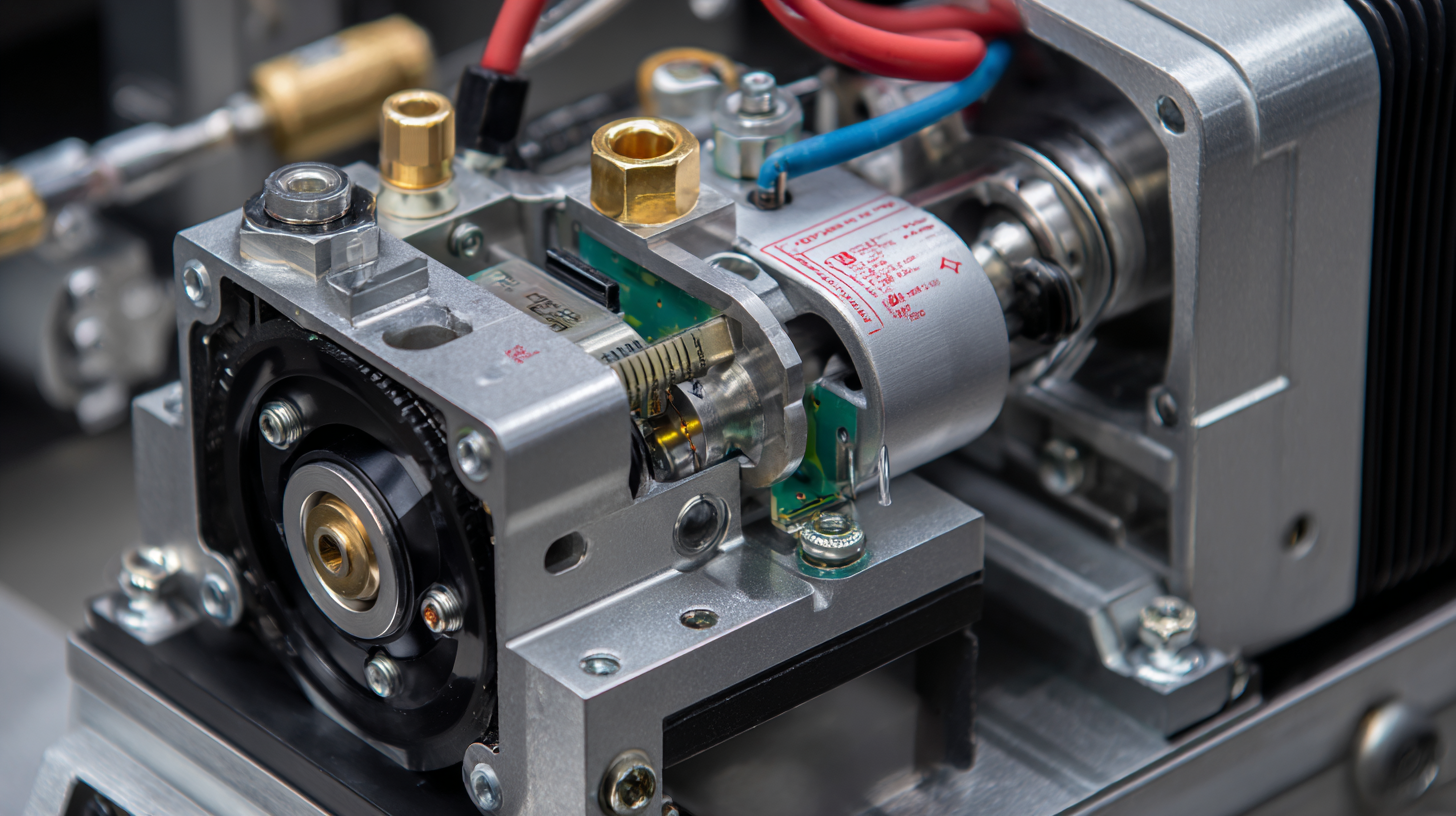

Understanding the Key Components of Vacuum Pumps for Enhanced Efficiency

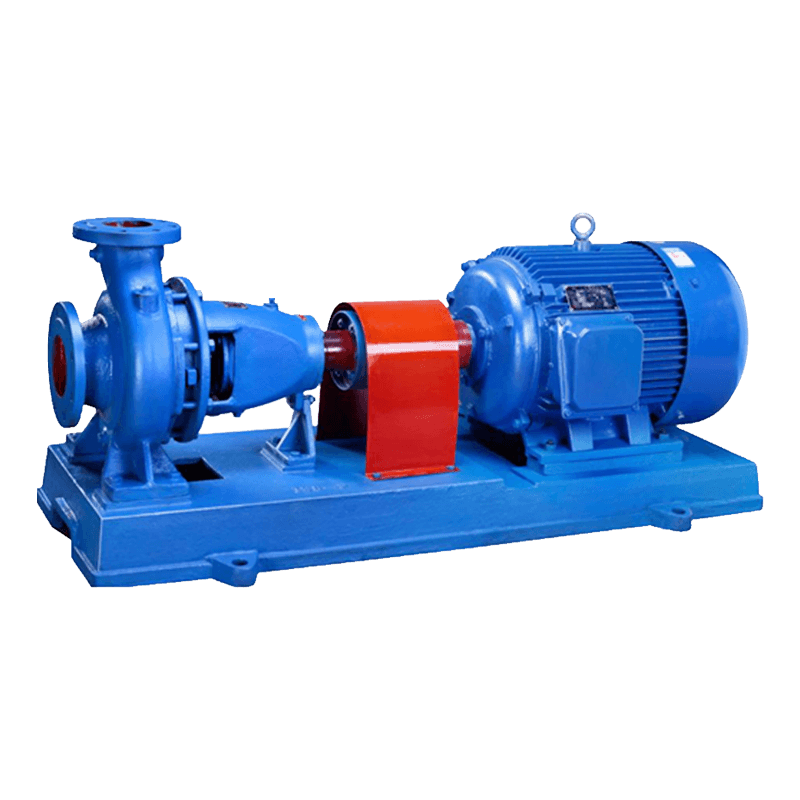

Understanding the key components of vacuum pumps is crucial for enhancing their efficiency and ensuring optimal performance. Vacuum pumps, whether in industrial, automotive, or household applications, rely on several critical parts, including motors, seals, and flow paths to function effectively. Recent innovations, such as gas-bearing motors in hybrid systems, highlight the importance of advanced technology in improving the design and efficiency of vacuum pumps.

These components not only contribute to the overall functionality but also impact their energy consumption and lifespan.

As the demand for vacuum pumps continues to grow across various sectors, including automotive and industrial markets, understanding these components becomes ever more essential. For instance, automotive vacuum pumps play a vital role in enhancing brake performance and achieving reduced emissions, showcasing their importance in modern vehicles. Additionally, continuous advancements in vacuum technology signify a trend towards more efficient systems that are better equipped to meet the increasing global demand.

By focusing on optimizing these essential components, users can significantly enhance the performance and reliability of vacuum pumps in their respective applications.

Common Problems in Vacuum Pump Components and Their Impact on Performance

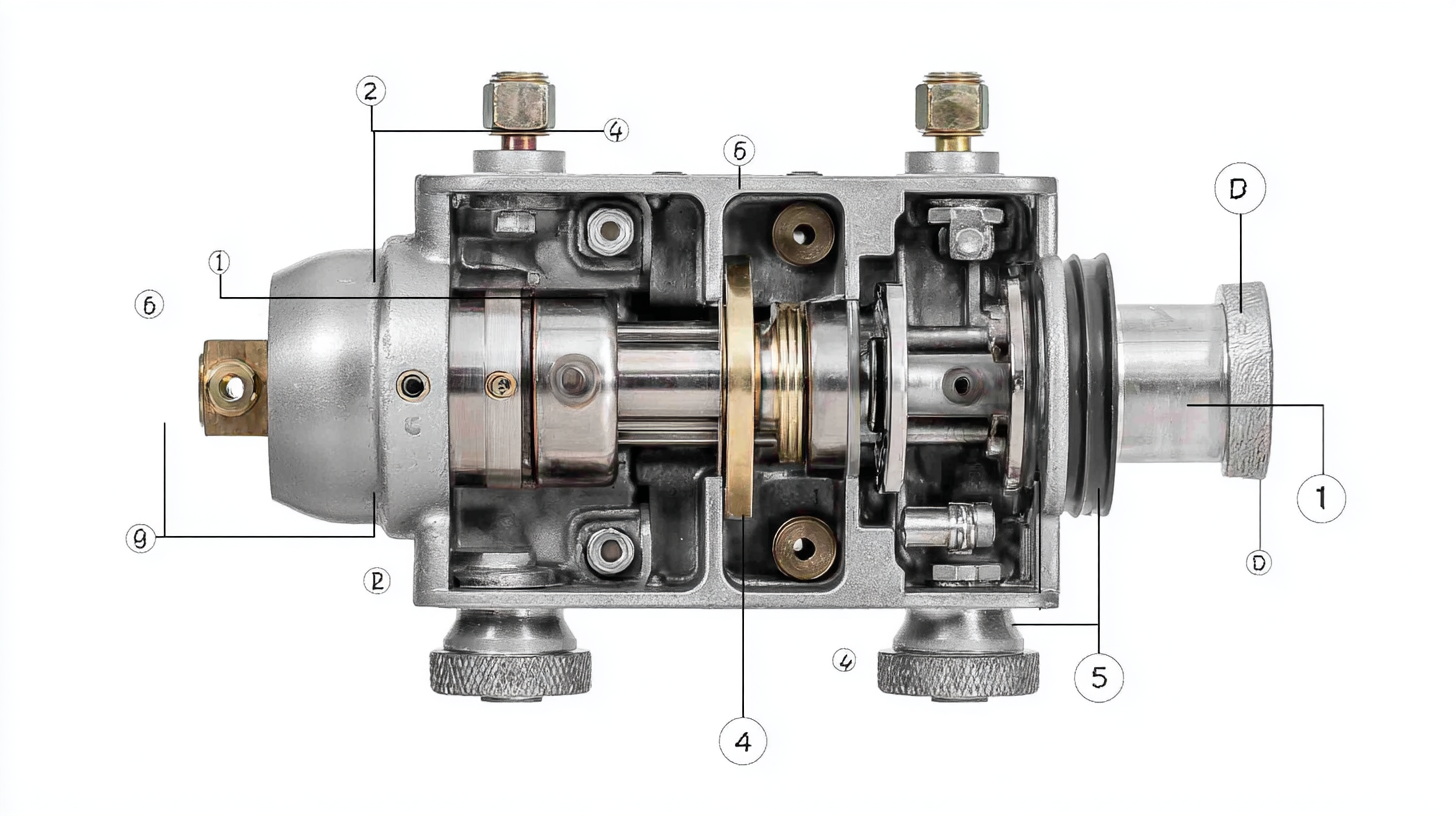

Vacuum pumps are essential in various industrial applications, but the performance of these pumps can be severely impacted by common component issues. According to a report from the Vacuum Technology Association, approximately 30% of vacuum pump failures are attributed to faults in their key components such as seals, bearings, and motors. Seals, for instance, are critical in maintaining the vacuum. When they wear out or become damaged, leaks can occur, leading to a significant drop in efficiency and performance. Research indicates that neglected seal maintenance can reduce a pump's efficiency by up to 15%, ultimately affecting production rates and operational costs.

Another common issue arises from bearing failure, which can lead to misalignment and increased friction, causing excessive heat. According to a study published in the Journal of Vacuum Science and Technology, nearly 25% of vacuum pump performance issues are related to bearing integrity. Timely inspection and replacement of bearings can mitigate these risks and extend the lifespan of the pump. Furthermore, ensuring that the motor operates within optimal parameters is vital; motors that run hot due to poor ventilation or overloading can degrade sooner, negatively impacting the entire system’s reliability. Addressing these common problems through proactive maintenance and component upgrades is crucial for ensuring optimal vacuum pump performance and minimizing operational disruptions.

Maintenance Tips for Extending the Life of Vacuum Pump Parts

To ensure the longevity and optimal performance of vacuum pump components, regular maintenance is essential. One crucial aspect of maintenance is checking for leaks, as even minor leaks can significantly reduce efficiency. Inspect all seals and gaskets for wear and replace them as necessary. Regularly tightening bolts and connections can also help maintain structural integrity and prevent unwanted air ingress.

Another important tip is to keep the vacuum pump clean. Accumulation of dust and debris can impede performance and lead to overheating. Scheduled cleaning routines should include not only the outer surfaces but also internal parts where dust can gather. Additionally, ensuring that the oil or lubricant used is the right type and is changed periodically will aid in reducing friction and wear on moving parts. By prioritizing these maintenance practices, you can extend the life of your vacuum pump and maintain optimal operational efficiency.

Addressing Common Issues with Top Vacuum Pump Components for Optimal Performance - Maintenance Tips for Extending the Life of Vacuum Pump Parts

| Component |

Common Issues |

Maintenance Tips |

Expected Lifespan |

| Pump Motor |

Overheating |

Regular cooling checks and ensuring proper ventilation |

5-10 years |

| Seals |

Leakage |

Inspect and replace seals regularly |

2-5 years |

| Vacuum Chamber |

Contamination |

Clean chamber after each use |

10-15 years |

| Filters |

Clogging |

Replace filters regularly based on usage |

1-3 years |

| Oil (for oil-sealed pumps) |

Degradation |

Change oil according to manufacturer recommendations |

Varies with usage |

Troubleshooting Guide for Frequent Vacuum Pump Component Failures

Vacuum pumps are crucial for various industrial applications, but they can encounter frequent issues that hinder their performance. One common problem is the failure of the pump's motor. Signs such as unusual noises or overheating can indicate that the motor is under stress. To troubleshoot, check for proper electrical connections and ensure that the motor is adequately lubricated. If the problem persists, it might be time to consider a replacement or a professional inspection.

Another common failure point is the pump seals. Over time, seals can wear out or suffer damage from exposure to harsh chemicals. This can lead to leaks, affecting the efficiency and functionality of the system. Regularly inspect seals for any signs of wear or degradation, and if leaks are detected, replace the damaged seals promptly to maintain optimal performance. Additionally, monitoring the vacuum level can help identify seal issues early, allowing for timely maintenance and preventing further complications down the line.

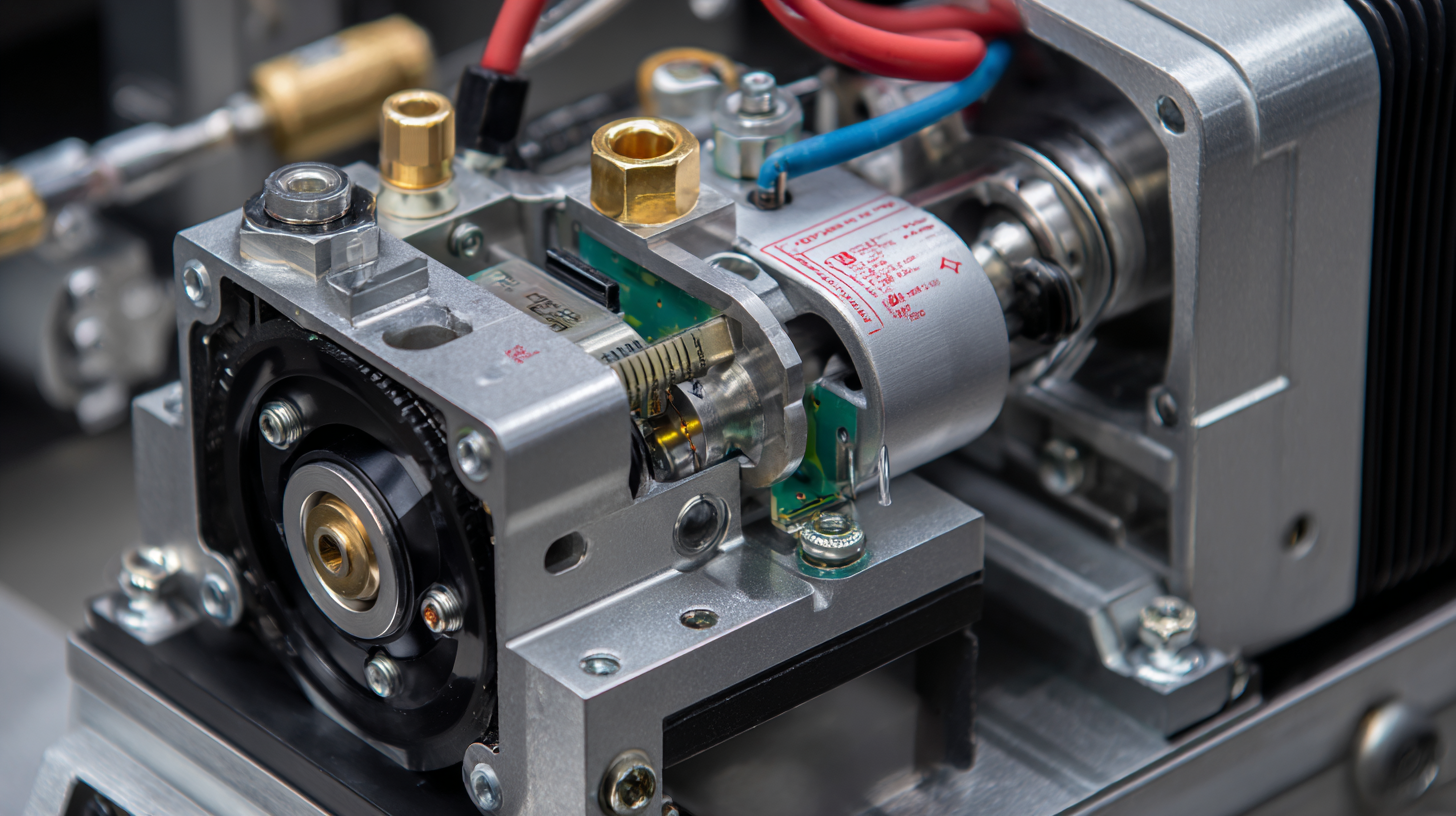

Upgrading Your Vacuum Pump Components for Improved Operation and Reliability

Upgrading your vacuum pump components is essential for enhancing the overall operation and reliability of your equipment. Over time, components can wear out or become inefficient, leading to decreased performance and increased maintenance costs. By investing in high-quality replacement parts, such as seals, bearings, and filters, operators can ensure a tighter seal and improved airflow, which translates to a more effective vacuum system. These upgrades not only enhance efficiency but also prevent potential breakdowns, extending the lifespan of the pump itself.

Moreover, selecting components that are compatible with your specific vacuum pump model is crucial. Compatibility ensures that each part functions harmoniously, reducing the risk of malfunctions and unwanted downtime. Upgrading to advanced materials and technologies can further improve resistance to chemical damage, heat, and wear, making your vacuum pump more resilient under demanding conditions. Emphasizing regular maintenance along with timely upgrades can significantly improve your vacuum system’s performance, driving productivity and reliability in your operations.