Revolutionizing Efficiency in Oil Fields: The Role of Chemical Injection Systems

In the ever-evolving landscape of the oil and gas industry, the integration of advanced technologies has become paramount to enhance operational efficiency and reduce costs. A significant innovation in this realm is the implementation of chemical injection systems, which play a critical role in optimally managing production processes. According to a report by Market Research Future, the global chemical injection market is projected to witness substantial growth, reaching approximately USD 6.56 billion by 2023, driven by the demand for improved production rates and the need to mitigate operational challenges. Chemical injection not only aids in corrosion control and paraffin removal but also enhances the overall reliability of oil field operations. This paper delves into the transformative impact of chemical injection systems, exploring their applications, benefits, and the potential for revolutionizing efficiency across oil fields.

Understanding Chemical Injection Systems and Their Importance in Oil Fields

Chemical injection systems play a crucial role in enhancing the efficiency and productivity of oil fields. These systems are designed to deliver specific chemicals that optimize various processes, such as improving reservoir performance, reducing the viscosity of crude oil, and preventing corrosion within pipelines. By carefully controlling the injection of these chemicals, operators can address challenges such as water influx and scale formation, ensuring a more sustainable extraction of oil resources.

Moreover, the importance of chemical injection systems extends beyond mere production enhancements. They facilitate safer operations by minimizing the risks associated with equipment failure caused by untreated corrosive elements. Additionally, these systems contribute to environmental protection efforts by managing the release of potentially harmful substances.

With the ongoing advancements in chemical formulations and injection technologies, oil companies are better equipped to maximize their output while minimizing operational costs and environmental impacts, thereby revolutionizing traditional methods within the oil industry.

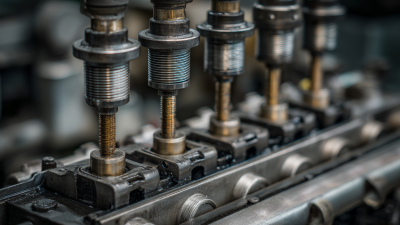

Key Components of Chemical Injection Systems: What You Need to Know

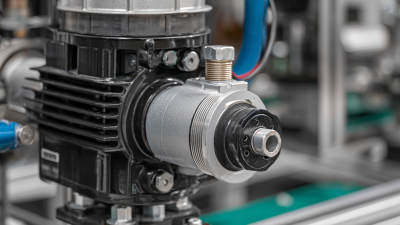

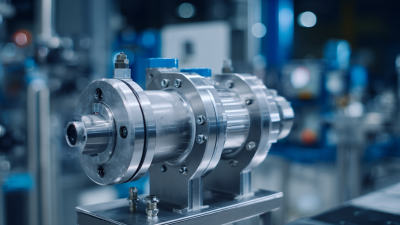

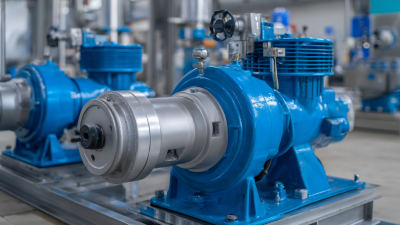

Chemical injection systems play a critical role in enhancing efficiency within oil fields by ensuring optimal performance of equipment and maximizing production. These systems typically consist of key components such as pumps, controllers, injection points, and storage tanks, all of which work in unison to deliver precise amounts of chemicals at the right times.

One crucial tip for optimizing chemical injection systems is to regularly monitor the integrity of all components. This not only prevents leaks and contamination but also ensures that chemical dosing remains accurate. Additionally, investing in automation can provide real-time data on system performance, allowing for quick adjustments and improved decision-making.

Another important factor to consider is the selection of the right chemicals for specific applications. Understanding the compatibility of chemicals with the oil field environment can significantly enhance performance and reduce operational costs. Careful analysis and testing can lead to better outcomes and a more sustainable injection process.

Implementing Efficient Chemical Injection Strategies for Maximum Output

In the quest for maximizing output in oil fields, efficient chemical injection strategies play a pivotal role. Liquid additives are often introduced into production processes to enhance oil recovery, mitigate corrosion, and reduce the buildup of undesirable substances. By carefully selecting and optimizing the types of chemicals used, operators can significantly improve productivity while minimizing costs. For instance, the use of surfactants can lower interfacial tension, facilitating better oil displacement and increasing production rates.

**Tips:** Optimize your chemical selection by conducting thorough evaluations of the specific conditions in your oil field. Regular monitoring of chemical effectiveness can lead to strategic adjustments that improve overall performance.

Additionally, implementing automated chemical injection systems enhances the precision of dosing and ensures that the right amount of chemicals is injected at the right time. This not only boosts efficiency but also reduces wastage and environmental impact. By leveraging advanced technologies such as IoT sensors for real-time data collection, operators can make informed decisions that lead to optimal chemical management and enhanced operational success.

**Tips:** Integrate a feedback system to adapt chemical strategies based on real-time performance data. This agility will help you stay ahead of potential issues and maintain high output levels.

Monitoring and Optimization Techniques for Chemical Injection in Oil Production

Chemical injection systems play a crucial role in enhancing efficiency within oil fields by optimizing the production process and reducing operational costs. Monitoring techniques, such as real-time data acquisition and analysis, are fundamental in ensuring that chemical dosages are administered precisely. This precision not only minimizes waste but also maximizes the effectiveness of the chemicals used, such as corrosion inhibitors and demulsifiers, ultimately leading to improved oil recovery rates.

Moreover, advanced optimization techniques, such as machine learning algorithms and predictive analytics, are increasingly being employed to analyze historical production data. These technologies can identify patterns and correlations that inform the optimal timing and amount of chemical injection. By integrating these sophisticated methods, oil producers can enhance their operational strategies, ensuring that chemical injection systems are not only efficient but also adaptable to changing field conditions. This proactive approach is pivotal in maintaining competitiveness in a rapidly evolving energy sector.

Revolutionizing Efficiency in Oil Fields: Chemical Injection Systems Performance

This chart illustrates the increasing efficiency of oil production through effective chemical injection systems over a period of five weeks. The data reflects the percentage of efficiency achieved each week as strategies were optimized.

Case Studies: Success Stories of Chemical Injection Systems Improving Efficiency

Chemical injection systems have emerged as a pivotal solution in enhancing operational efficiency within oil fields. One notable case study involves a major oil producer in the Permian Basin, which implemented a sophisticated chemical injection system aimed at optimizing production rates. By precisely delivering chemicals to stimulate oil flow and reduce viscosity, the company reported a 20% increase in output within the first quarter of implementation. This success was attributed to real-time monitoring and automated controls that ensured the exact dosage of chemicals administered, reducing waste and increasing profitability.

Another compelling example can be found in offshore drilling operations in the North Sea. Here, chemical injection systems were deployed to combat scale formation and hydrate issues, which often hinder production efficiency. The integration of these systems not only minimized downtime caused by maintenance but also extended equipment life by protecting critical components from corrosive environments. As a result, the operator experienced a significant reduction in operational costs and an overall enhancement in production resilience. These case studies illustrate the transformative impact of chemical injection systems, driving efficiency and productivity in an increasingly competitive industry.

Related Posts

-

How to Maximize Efficiency in Your Solar Pump System with Latest Technology Innovations

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

-

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.