10 Essential Tips for Choosing a Chemical Metering Pump

Choosing the right chemical metering pump can greatly impact efficiency and safety in various applications. These pumps are essential in accurately delivering precise amounts of chemicals. With numerous options available, careful consideration is vital.

When selecting a chemical metering pump, think about the specific needs of your system. Different industries require different functionalities. Assess the fluid characteristics, including temperature and viscosity. Each pump type has unique strengths and weaknesses. Understanding these can prevent future problems.

Investing time in research is crucial. Speak with suppliers and read reviews. Mistakes can be costly, affecting both performance and safety. A good decision today can improve productivity and reduce risks. Your choice matters more than you might realize.

Understanding the Functionality of Chemical Metering Pumps in Industry

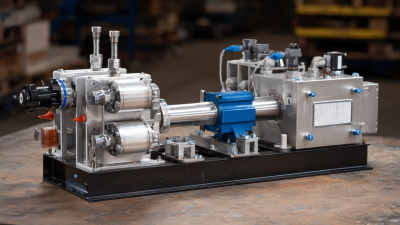

Chemical metering pumps play a crucial role in various industries. They accurately dispense and control the flow of chemicals. This precision is vital in sectors like water treatment, agriculture, and pharmaceuticals. According to a recent industry report, these pumps can achieve an accuracy of ±1%. Such precision helps to minimize waste and improve efficiency.

Understanding the functionality of these pumps is essential. They are designed to handle various chemicals, including corrosive and viscous fluids. Some models can operate under high pressures, making them suitable for demanding applications. However, choosing the wrong pump can result in costly downtimes. Maintenance issues can arise if the pump does not suit the specific chemical being dispensed. For example, using a non-compatible material can lead to pump failure.

Proper selection involves considering factors like flow rate, pressure, and chemical compatibility. A report highlighted that 30% of metering pumps fail due to improper selection. This statistic underscores the importance of understanding not just the pump design, but also the chemicals in use. Knowledge gaps in this area can lead to operational inefficiencies. Therefore, review options carefully and consider all relevant factors.

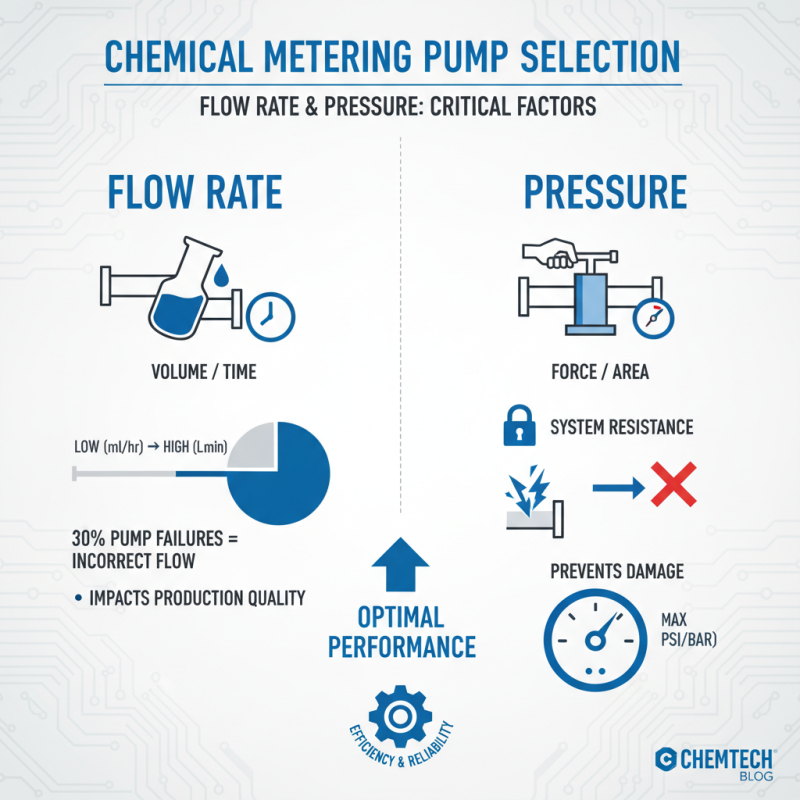

Key Factors Affecting Pump Selection: Flow Rate and Pressure Requirements

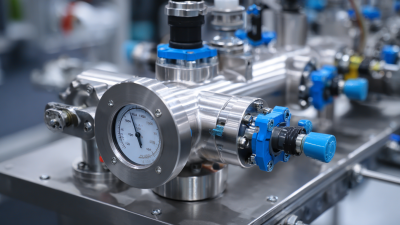

When selecting a chemical metering pump, understanding flow rate and pressure is crucial. Flow rate refers to the volume of liquid delivered by the pump over time. This can vary widely, from a few milliliters per hour to thousands of liters per minute. According to industry reports, approximately 30% of pump failures stem from incorrect flow rates. Ensuring the right flow rate is not just about efficiency; it directly impacts production quality.

Pressure requirements also play a vital role. Many applications require the pump to generate a specific pressure to overcome system resistance. Industry data shows that over 40% of operators underestimate this need. Insufficient pressure can lead to incomplete dosages. On the other hand, excessive pressure may strain the pump and lead to early wear and tear. Understanding the system's dynamics is essential for a successful pump operation.

Installing a pump without proper calculations can invite problems. Many users fail to revisit their initial parameters. Real-world applications often introduce unforeseen variables. These include changes in fluid viscosity and temperature fluctuations. Regular assessments can lead to better choices and longevity.

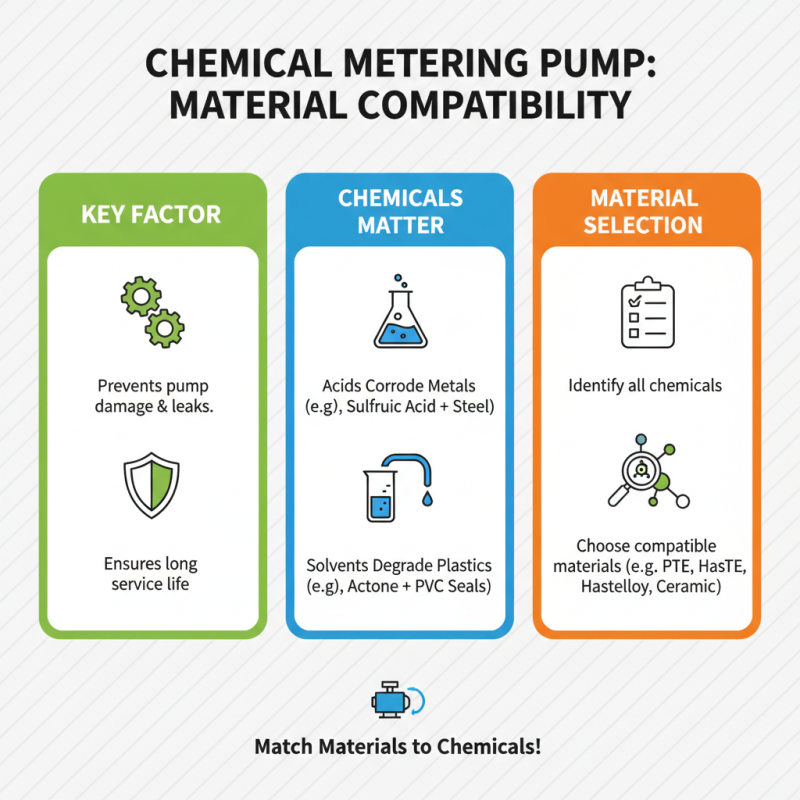

Material Compatibility: Ensuring Pump Longevity in Chemical Applications

Material compatibility is a critical factor in selecting a chemical metering pump. Different materials react uniquely with various chemicals. This is especially important in preventing pump damage. For example, certain acids can corrode metal components. Likewise, some solvents may degrade plastics. Evaluating the intended chemicals helps identify appropriate materials for the pump.

Take time to review material safety data sheets (MSDS) for chemicals involved. These sheets provide valuable information on compatibility. However, sometimes the information can be overwhelming. It might not address every scenario. Testing on a smaller scale can yield insights before full-scale implementation. Pilot projects can reveal unforeseen issues, like unexpected wear.

Consider the environment where the pump operates. High temperatures or extreme pH levels can affect material behavior. Always analyze system dynamics, as they influence material lifespan too. While it may seem like extra work, ensuring compatibility is vital for long-term success. Ignoring this aspect can lead to unexpected downtime and costly repairs. A thorough approach prevents future headaches.

Evaluating Control Options: Manual vs. Automated Metering Solutions

When evaluating control options for chemical metering pumps, the choice between manual and automated solutions can be crucial. Manual pumps require a hands-on approach. Operators must monitor flow rates and make adjustments frequently. This can be tedious and prone to human error. For small operations, manual control might suffice. Yet, as production scales, inefficiencies can stack up.

Automated metering solutions offer more precision. They can adjust flow rates in real-time based on system demands. This reduces the need for constant oversight and can improve consistency in dosing. However, automation comes with its challenges. Initial setup can be complex and requires careful calibration. Systems may also need regular maintenance to ensure they function correctly.

Balancing between the two types demands careful consideration. Manual systems provide flexibility but can lead to inconsistencies. Automated systems enhance accuracy but can be costly and require technical expertise. Assessing your operation's scale, budget, and expertise is essential. Making the right choice impacts not just operations but overall safety and efficiency.

Comparison of Manual vs. Automated Metering Solutions

This chart compares the key features and benefits of manual and automated chemical metering pumps. It highlights aspects such as accuracy, ease of use, maintenance, and cost-effectiveness.

Maintenance Considerations: Key Practices for Optimal Pump Performance

When maintaining a chemical metering pump, regular inspection is vital. A study from the Chemical Engineering journal reported that pumps can lose up to 25% efficiency without proper upkeep. Look for signs of wear, leaks, and unusual sounds. These indicators can reveal potential failures before they escalate. Regular cleaning of the pump and associated lines is equally important to avoid blockages and ensure smooth operation.

Calibration is another key practice. Inaccurate flow rates can directly impact process efficiency. The American Society of Mechanical Engineers recommends recalibration every six months to maintain accuracy. Operators should also monitor pressure readings. Fluctuations can signify issues that may diminish performance. Additionally, checking the chemical compatibility of pump materials extends the lifespan of the pump.

Even with regular maintenance, not all practices are foolproof. Sometimes, pumps still fail due to unforeseen circumstances. Having a contingency plan in place can mitigate downtime. Noting the pump’s operating history can also provide insights into performance trends. This combined approach ensures that any deviations from normal operations are addressed promptly. Each element contributes to the longevity and reliability of the pump system.

Related Posts

-

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

-

Understanding the Importance of Chemical Metering Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

Unlocking the Secrets of Liquid Pumps and Their Impact on Modern Technology

-

Why Choose a Chemical Metering Pump for Precise Liquid Handling in Your Industry

-

How to Choose the Right Chemical Metering Pump for Your Needs?

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.