Exploring the Future of Best Slurry Pump Parts Technology Trends for Global Buyers in 2025

As the global demand for efficient and effective slurry handling systems continues to rise, the importance of advanced slurry pump parts technology has never been more paramount. According to a recent industry report from MarketsandMarkets, the global slurry pump market is projected to reach USD 13.6 billion by 2025, driven by increasing investments in sectors such as mining, construction, and wastewater treatment. In this evolving landscape, understanding the latest trends in slurry pump parts technology is crucial for buyers looking to optimize their operations and reduce maintenance costs.

Advances in material science, automation, and design innovations are setting the stage for a new era of slurry pumping solutions, making it essential for stakeholders to stay informed about emerging technologies and best practices. This blog will delve into the anticipated developments in slurry pump parts for 2025, providing insights that can help global buyers make informed decisions in a competitive market.

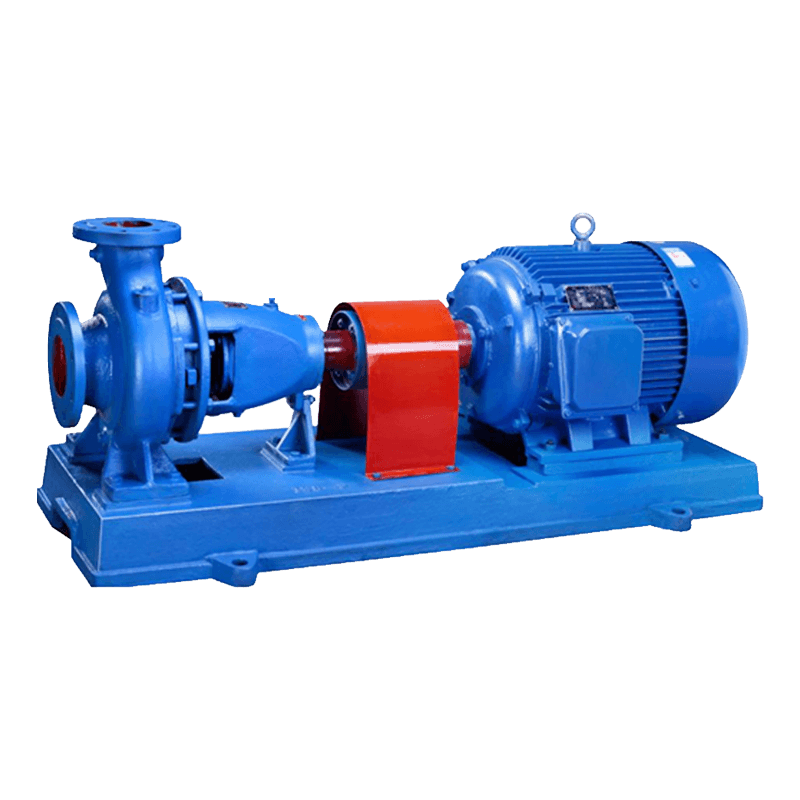

Innovative Materials: Enhancing Durability and Efficiency of Slurry Pump Parts

As the slurry pump industry moves toward 2025, innovative materials are set to revolutionize the durability and efficiency of slurry pump parts. Traditional materials often struggle under the demanding conditions typical of slurry transport, where wear and corrosion can lead to reduced performance and increased downtime. To tackle these challenges, manufacturers are increasingly turning to advanced composites and high-strength alloys that promise enhanced resistance to abrasion and chemical exposure. These materials not only help extend the lifespan of pump components but also minimize maintenance costs, making them a sustainable choice for industries reliant on slurry transport.

In addition to improved material properties, enhanced manufacturing techniques are paving the way for more precise and efficient slurry pump parts. Innovations such as 3D printing and advanced casting methods allow for the creation of complex geometries that optimize fluid dynamics within the pump. These techniques ensure that the parts are not only lighter but also effectively reduce energy consumption during operation. As global buyers seek reliable solutions in an ever-evolving market, the emphasis on innovative materials and state-of-the-art manufacturing processes will play a crucial role in shaping the future of slurry pump technology.

Smart Technology Integration: IoT and Automation in Slurry Pumps

As we look towards 2025, the integration of smart technology in slurry pump systems is set to revolutionize the industry. The rise of the Internet of Things (IoT) and automation is creating a paradigm shift, enabling real-time monitoring and predictive maintenance. According to a report from Market Research Future, the global smart pump market is projected to grow at a CAGR of 5.7%, driven largely by advancements in IoT technology. Slurry pumps equipped with smart sensors can now report performance metrics, enabling operators to make data-driven decisions that enhance efficiency and reduce operational costs.

Automation is also playing a crucial role in improving the reliability of slurry pumping systems. With the implementation of AI and machine learning algorithms, these pumps can adapt to varying conditions, optimizing performance dynamically. A report by Deloitte highlights that companies employing automated slurry pump technologies can see a decrease in downtime by up to 30%, significantly impacting overall productivity. This trend toward smart integration is not just about enhancing existing functionalities but also about shaping a more sustainable and resilient supply chain for global buyers in a competitive market.

Sustainability Trends: Eco-Friendly Solutions for Slurry Pump Components

As the global industrial landscape shifts towards sustainability, the

slurry pump industry is embracing eco-friendly solutions that adhere to environmental standards while maintaining operational efficiency.

In 2025, we can expect to see a surge in the development of slurry pump components that prioritize the use of

sustainable materials, such as

recycled metals and

biocompatible polymers.

These innovations not only reduce the environmental footprint of manufacturing processes but also enhance the

durability and performance of pump parts.

Additionally, advancements in technology are paving the way for improved energy efficiency in slurry pumps.

Manufacturers are increasingly focusing on creating designs that minimize energy consumption through enhanced

hydraulic performance and advanced smart monitoring systems. These systems allow for

real-time analysis of pump performance, enabling operators to optimize

energy usage and reduce waste.

By embracing these

eco-friendly initiatives, buyers can contribute to a

more sustainable future while reaping the benefits of

cutting-edge technology in their operations.

Market Forecast: Impact of Global Demand on Slurry Pump Part Innovations

The global demand for slurry pump parts is projected to catalyze significant innovations in technology by 2025. As the slurry pump market evolves, advanced materials and designs will enhance performance and efficiency, addressing the rising need for durable and reliable pumping solutions. Recent reports indicate that the heavy-duty pumps market is set to grow steadily, with an estimated increase driven by industrial advancements and application demands.

Furthermore, the diaphragm pump market is expected to see revenues soaring to $9.3 billion by 2030. This surge reflects the growing requirement for precise fluid handling in various industries, underscoring the necessity for innovative pump solutions. As companies continue to invest in enhanced product capabilities, the synergy between global demand and technological progress will shape the future landscape of slurry pump parts, emphasizing a shift towards smarter and more efficient systems.

Future Trends in Slurry Pump Parts Technology - Market Forecast 2025

Key Players and Collaborations: Shaping the Future of Slurry Pump Technologies

The slurry pump industry is experiencing transformative changes driven by key players and strategic collaborations. As of 2023, the global slurry pump market size is projected to reach approximately $5.8 billion by 2025, growing at a CAGR of about 5.2%. This growth can be attributed to the increasing demand for efficient and durable pumping solutions across sectors such as mining, construction, and wastewater treatment. Leading companies like Weir Group, Metso Outotec, and Schurco Slurry are at the forefront, innovating new materials and designs to enhance pump performance and longevity.

Collaborations among these industry titans are reshaping the landscape of slurry pump technologies. For instance, partnerships aimed at developing advanced pump components that withstand abrasive materials are becoming increasingly common. A recent report highlighted that successful joint ventures between equipment manufacturers and material science firms are leading to the creation of pumps that can reduce operational costs by up to 20% while improving energy efficiency. As we move towards 2025, these strategic alliances will be crucial for addressing the challenges of demanding operational environments and meeting the strict regulatory standards set by various industries.