Essential Guide to Selecting the Best Slurry Pump Parts for Optimal Performance

In the world of industrial applications, selecting the right Slurry Pump Parts is crucial for ensuring optimal performance and longevity of your equipment. As industries worldwide increasingly rely on efficient and reliable pumping solutions, understanding the significance of high-quality components becomes paramount. With the rise of "Made in China" products, the emphasis on quality improvements has led to a surge in globally popular slurry pump parts.

This guide aims to walk you through essential considerations when choosing the best slurry pump parts, from material specifications to compatibility and durability, ensuring that your pumping systems operate at their fullest potential. Whether you are involved in mining, construction, or wastewater management, making informed decisions about your slurry pump parts can dramatically impact operational efficiency and cost-effectiveness in the long run.

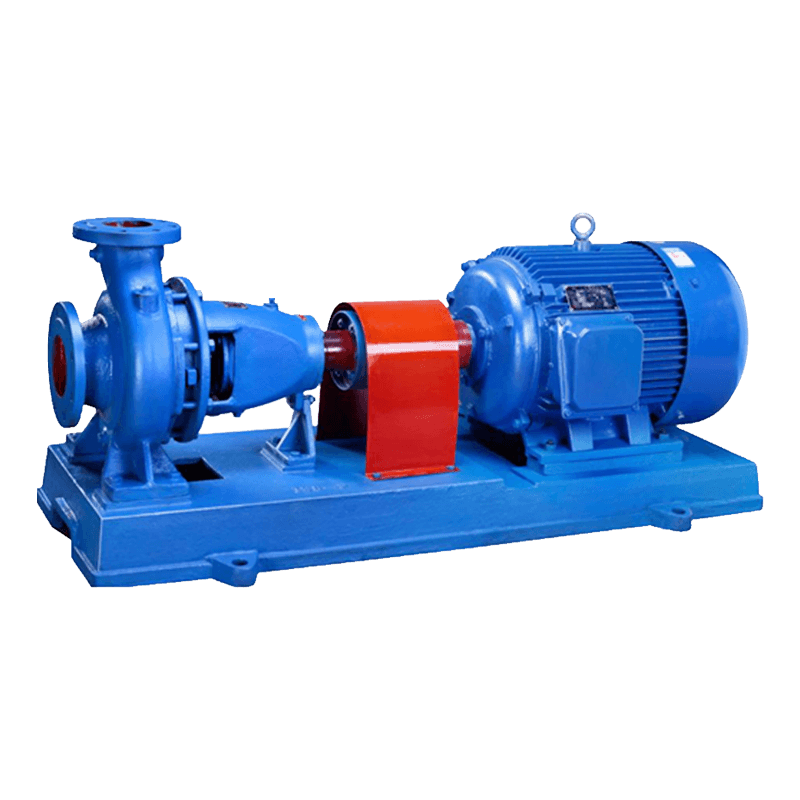

Understanding the Different Types of Slurry Pump Parts Available in the Market

When selecting slurry pump parts, understanding the various types available in the market is crucial for ensuring optimal performance. Slurry pumps, widely used in industries like mining and construction, handle abrasive and viscous materials. According to a recent industry report by Market Research Future, the global slurry pump market was valued at approximately $3.2 billion in 2020 and is expected to grow at a CAGR of 5.2% from 2021 to 2027. This growth is largely driven by advancements in manufacturing technologies and increasing demand for efficient pumping solutions.

The key components of slurry pumps include impellers, casings, liners, and bearings, each designed to cater to specific operational conditions. For instance, abrasion-resistant impellers made from high-chrome alloys are essential for applications involving highly abrasive materials, while rubber linings may be preferred in less aggressive environments. A 2021 study published in the Journal of Hydraulic Engineering emphasizes that selecting the appropriate material for each part can significantly extend the lifespan of the pump and decrease maintenance costs. By investing time and resources into understanding these components, industries can effectively optimize their slurry pump systems for better efficiency and reliability.

Performance Comparison of Different Slurry Pump Parts

This chart illustrates the performance efficiency of various slurry pump parts based on their durability and usability. The data represents the average performance metrics of different components:

- Pump Impellers: 85%

- Pump Casings: 75%

- Seals: 70%

- Wear Liners: 80%

- Drive Shafts: 65%

Key Factors to Consider When Choosing Slurry Pump Parts for Your Application

When selecting slurry pump parts, several key factors should guide your decision to ensure optimal performance for your application.

First, assess the type of slurry being pumped. The size and nature of the solids within the slurry can affect the choice of materials and design for the pump components such as impellers and liners.

Heavy, abrasive slurries require sturdier materials, like high-chrome iron or rubber, to withstand wear and prolong the lifespan of the pump.

Heavy, abrasive slurries require sturdier materials, like high-chrome iron or rubber, to withstand wear and prolong the lifespan of the pump.

Another crucial factor is the pump's operating conditions. Consider the flow rate and pressure requirements of your application, as these parameters will influence the selection of pump type and size.

Additionally, it's vital to evaluate the compatibility of the parts with the specific slurry chemistry. Some materials can corrode or degrade when exposed to certain chemicals, so ensuring material compatibility will prevent premature failures and costly downtime.

By carefully considering these factors, you can choose the right slurry pump parts that enhance performance and reliability.

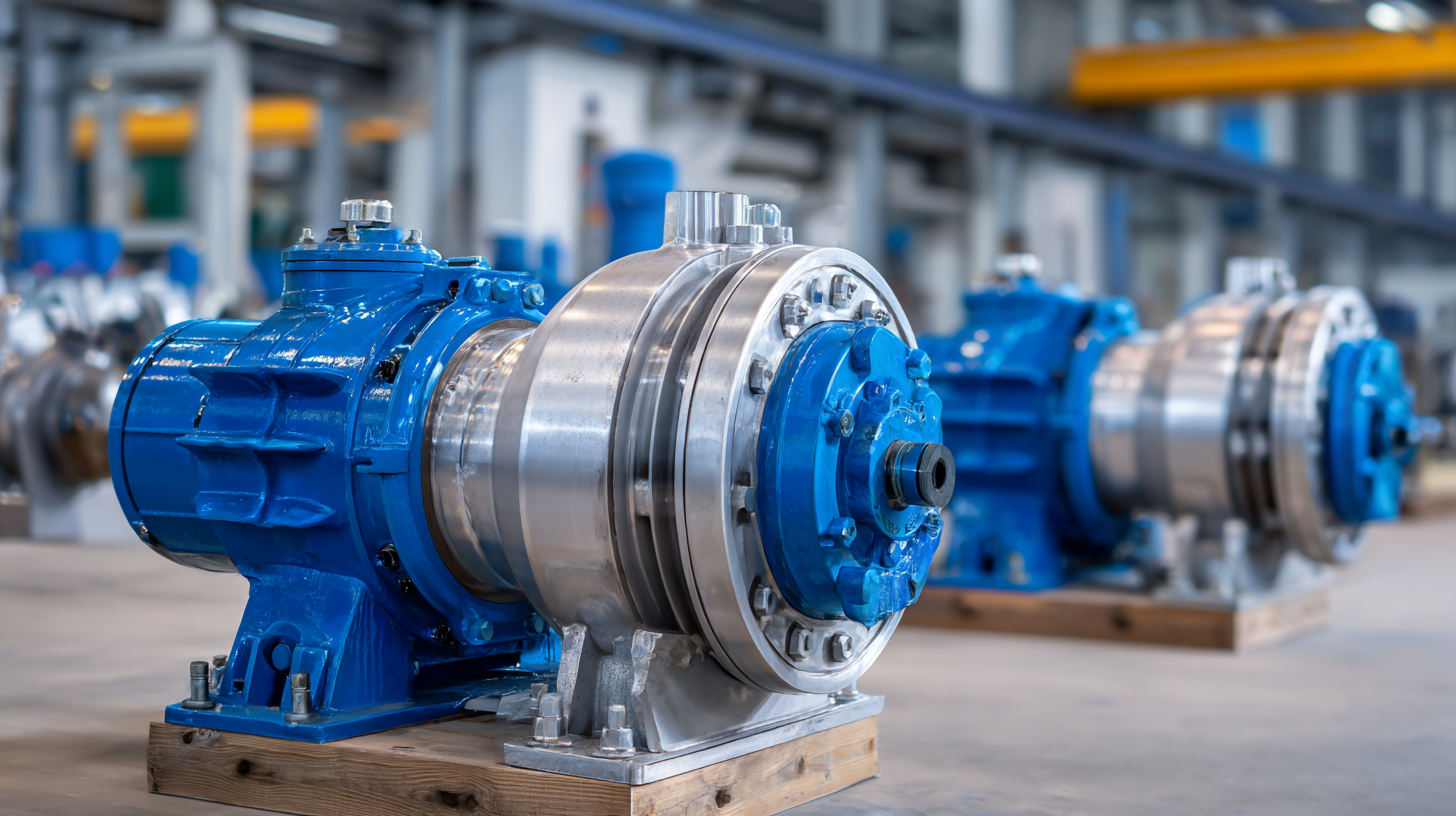

How to Evaluate the Quality and Durability of Slurry Pump Components

When it comes to selecting slurry pump parts, evaluating the quality and durability of the components is crucial to ensure optimal performance. Begin your assessment by examining the materials used in the construction of the parts. High-quality materials such as stainless steel, rubber, and specialized alloys can significantly enhance the lifespan of the components under harsh operating conditions. Always check for corrosion resistance and wear properties, as these will determine the pump's reliability over time.

**Tip:** Consider parts tested and certified by relevant industry standards. Look for suppliers that provide documentation on the quality control processes involved in manufacturing their slurry pump components.

Another aspect to consider is the design of the parts, particularly the impellers and casing. A well-designed impeller can improve efficiency and reduce energy consumption, while an appropriately engineered casing prevents leaks and ensures robust operation. It’s beneficial to choose parts that offer replaceability and compatibility with your existing pump system, ensuring ease of maintenance and fewer disruptions to your operations.

**Tip:** Engage with manufacturers or suppliers for expert recommendations on parts that not only meet your performance expectations but also align with the maintenance schedules of your operations.

Maintenance Tips to Extend the Life of Your Slurry Pump Parts

When it comes to ensuring the longevity and efficiency of your slurry pump parts, proper maintenance is key. Regular inspection of the pump components can help identify wear and tear before they lead to more significant issues. For example, periodically checking the impeller for signs of erosion can prevent unexpected breakdowns and costly repairs.

Another essential tip is to keep the pump and its surroundings clean. Accumulated debris can obstruct the functioning of the pump, leading to inefficiencies and potential damage. Implementing a routine cleaning schedule will not only maintain optimal performance but also enhance the overall lifespan of the pump parts.

Lastly, don’t underestimate the importance of proper lubrication. Regularly lubricate moving components as per the manufacturer’s recommendations to reduce friction and wear. This simple step can significantly improve the operational efficiency of your slurry pump, ensuring it runs smoothly for years to come.

Cost-Effective Solutions for Upgrading Your Slurry Pump Parts for Better Performance

When considering upgrades to your slurry pump parts, it's crucial to focus on cost-effective solutions that enhance performance. Recent innovations have shown that advanced slurry pumping systems can deliver significant productivity gains while reducing operational costs. For instance, modern pumps are designed for durability and efficiency, offering longer lifespans and reduced maintenance requirements. This shift not only maximizes uptime but also minimizes disruptions in production, which is critical in the mining industry.

**Tip:** Regularly assess your pump's performance metrics such as flow rate and energy consumption. Maintaining optimal levels can help identify when it’s time to upgrade components.

One of the emerging trends in slurry pump technology is increased reliability, particularly in harsh environments. Manufacturers are continuously improving their offerings to combat challenges like supply chain issues and labor shortages. By investing in built-to-last equipment and sourcing high-quality parts, operators can expect not only improved service continuity but also a reduction in overall costs.

**Tip:** Consider impact-reducing technologies in your upgrades. These innovations can significantly enhance the efficiency of your slurry handling processes, allowing for smoother operations even in abrasive conditions.

Essential Guide to Selecting the Best Slurry Pump Parts for Optimal Performance

| Part Name |

Material |

Wear Resistance |

Cost (USD) |

Recommended Upgrade |

| Impeller |

High Chrome Alloy |

Excellent |

150 |

Upgrade to Ceramic Coating |

| Volute Liner |

Rubber |

Good |

120 |

Consider Polyurethane |

| Shaft |

Stainless Steel |

Very Good |

200 |

Upgrade to High Strength Alloy |

| Gland Packing |

Graphite |

Moderate |

30 |

Switch to Mechanical Seal |

| Bearing |

Bronze |

Good |

50 |

Upgrade to Self-Lubricating Bearing |

Heavy, abrasive slurries require sturdier materials, like

Heavy, abrasive slurries require sturdier materials, like