Innovative Liquid Pumps: Transforming Industrial Efficiency and Performance

The advancements in liquid pump technology are reshaping the landscape of industrial efficiency and performance, offering significant potential for operational optimization across various sectors. According to a report by Research and Markets, the global liquid pump market is expected to reach $60 billion by 2026, fueled by the increasing demand for automation and streamlined processes in manufacturing and chemical industries.

Innovative liquid pumps are now equipped with smart features that enhance energy efficiency and reduce operational costs, making them vital components in modern industrial setups. With the integration of IoT and AI technologies, these pumps not only ensure precise fluid management but also enable predictive maintenance, significantly decreasing downtime. As industries aim to improve their sustainability and productivity levels, the role of cutting-edge liquid pump systems becomes ever more critical, paving the way for enhanced performance and resource optimization.

Innovative liquid pumps are now equipped with smart features that enhance energy efficiency and reduce operational costs, making them vital components in modern industrial setups. With the integration of IoT and AI technologies, these pumps not only ensure precise fluid management but also enable predictive maintenance, significantly decreasing downtime. As industries aim to improve their sustainability and productivity levels, the role of cutting-edge liquid pump systems becomes ever more critical, paving the way for enhanced performance and resource optimization.

Identifying Key Innovations in Liquid Pump Technology for Industry

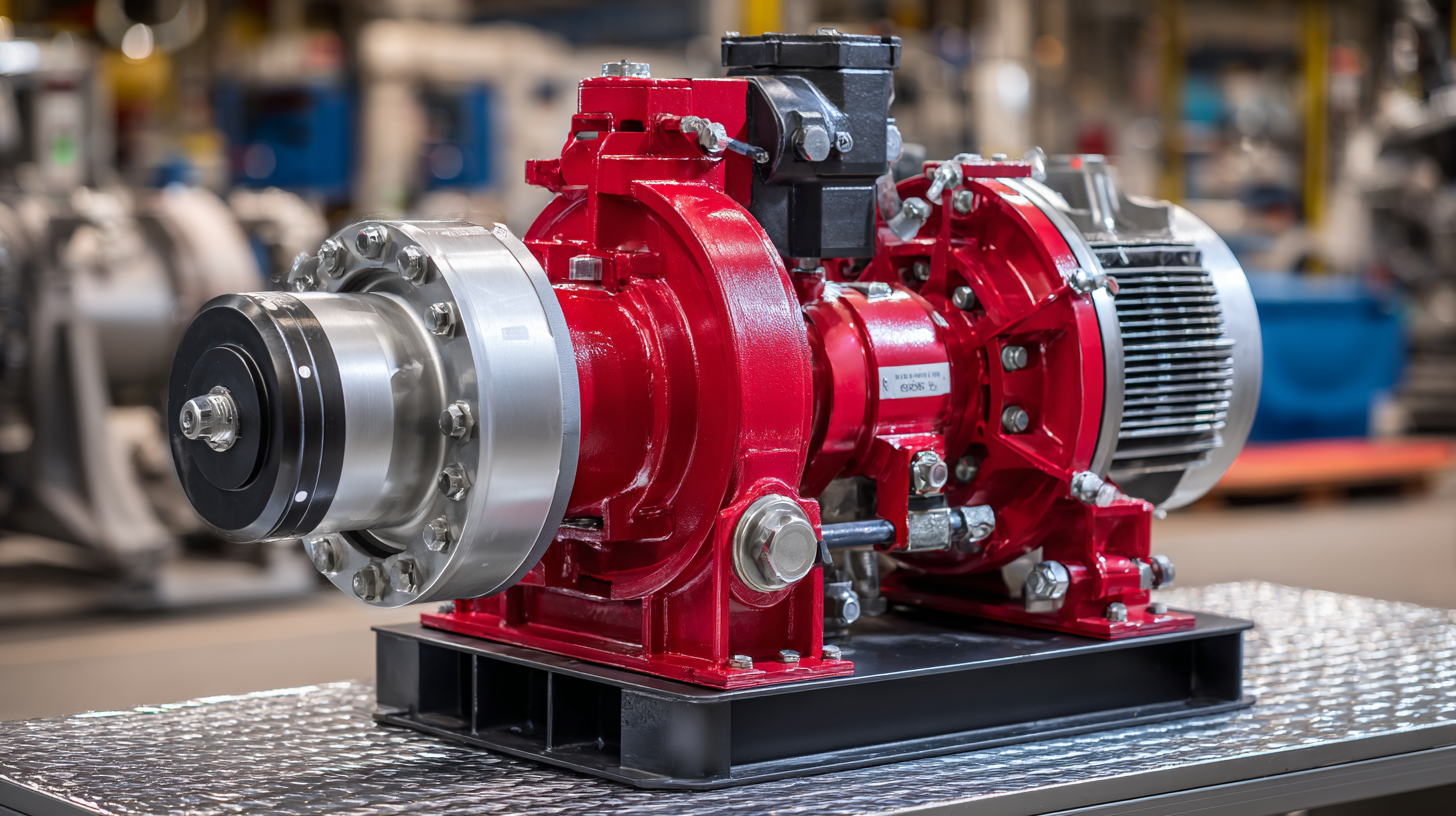

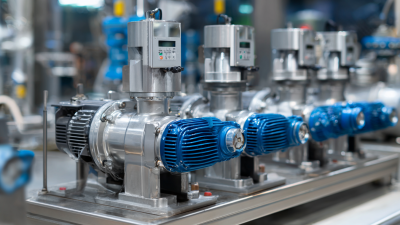

In recent years, innovations in liquid pump technology have significantly boosted industrial efficiency and performance. Among the key advancements, smart control systems stand out, allowing pumps to be monitored and adjusted in real-time. This capability not only enhances operational reliability but also reduces energy consumption, contributing to more sustainable practices in various sectors. By integrating IoT technology, these smart pumps can communicate with other machinery, ensuring synchronized operations and minimizing downtime.

In recent years, innovations in liquid pump technology have significantly boosted industrial efficiency and performance. Among the key advancements, smart control systems stand out, allowing pumps to be monitored and adjusted in real-time. This capability not only enhances operational reliability but also reduces energy consumption, contributing to more sustainable practices in various sectors. By integrating IoT technology, these smart pumps can communicate with other machinery, ensuring synchronized operations and minimizing downtime.

Tips: When selecting a liquid pump for your facility, consider models with adaptive control features. These can lead to significant energy savings and increased system longevity.

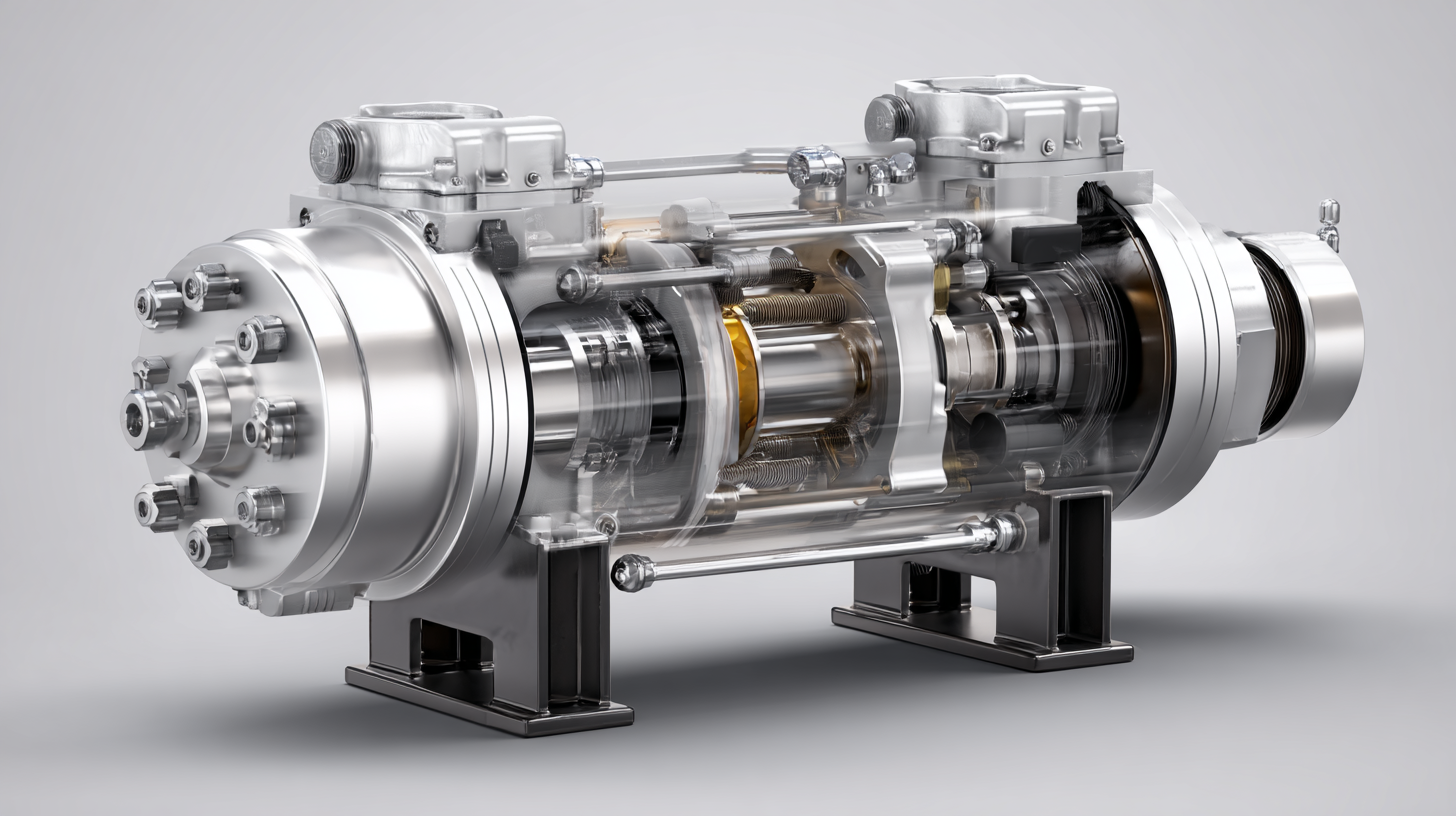

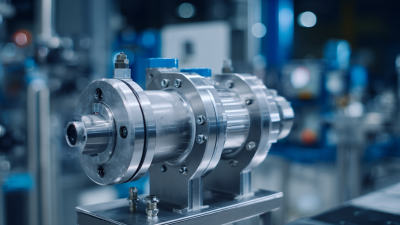

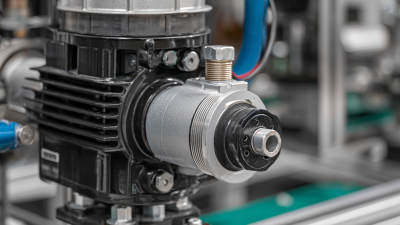

Another notable innovation is the development of advanced materials that improve pump durability and resistance to corrosion. These materials extend the lifespan of pumps, especially in harsh environments, leading to reduced maintenance costs and less frequent replacements. Additionally, manufacturers are now offering modular designs that allow for easy upgrades and repairs, making it more efficient to adapt to evolving industrial needs.

Tips: Keep an eye on emerging materials in pump technology if your operations involve corrosive fluids. Investing in the latest designs could drastically enhance your system’s performance and reliability.

Understanding the Role of Liquid Pumps in Enhancing Industrial Efficiency

Liquid pumps play a crucial role in modern industrial processes, significantly enhancing efficiency and performance across various sectors. These innovative devices are designed to transport liquids with precision, reducing waste and energy consumption. By implementing advanced pump technologies, industries can optimize their operations, leading to smoother workflows and improved productivity. The integration of smart features, such as automation and remote monitoring, further refines liquid pump functionality, enabling real-time adjustments and predictive maintenance.

In addition to operational efficiency, liquid pumps also contribute to environmental sustainability. By utilizing energy-efficient designs and materials, modern pumps minimize their ecological footprint while maintaining high performance standards. This transformation not only meets regulatory requirements but also aligns with the growing industrial emphasis on sustainable practices. As sectors continue to evolve and adapt to new challenges, the importance of liquid pumps in enhancing industrial efficiency cannot be overstated; they are integral to driving innovation and competitive advantage in today’s fast-paced market.

Assessing Performance Metrics for Modern Liquid Pumps in Various Applications

The performance metrics of modern liquid pumps are crucial in determining their efficiency and applicability across various industries. Factors such as flow rate, pressure, and energy consumption play vital roles in evaluating a pump's capability. For instance, high flow rates are essential in large-scale applications like chemical processing, where the seamless movement of fluids impacts overall production timelines. Additionally, the pressure capabilities of a pump are pivotal in applications involving high-viscosity liquids, necessitating designs that can withstand and deliver fluids under significant pressure without compromising safety or operational integrity.

In addition to flow and pressure, energy efficiency has emerged as a critical performance metric due to rising operational costs and environmental considerations. The integration of advanced technologies, such as variable frequency drives (VFDs) and smart monitoring systems, allows for more precise control of pump operations, optimizing energy use according to real-time demands. This not only enhances performance but also contributes to sustainability goals within industrial sectors. By continuously assessing these performance metrics, industries can select pumps that not only meet their immediate operational needs but also align with long-term efficiency and environmental objectives.

Implementing Best Practices for Optimizing Liquid Pump Systems

Optimizing liquid pump systems is crucial for enhancing industrial efficiency and performance. According to a report by Grand View Research, the global pump market is projected to reach USD 100 billion by 2025, with liquid pumps playing a significant role in various sectors including oil and gas, water management, and chemical processing. Successful implementation of best practices can lead to energy savings of up to 30%, highlighting the importance of efficiency in pump operations.

To achieve optimal performance, industries should prioritize regular maintenance and monitoring. The adoption of predictive maintenance techniques, utilizing IoT and AI technologies, enables companies to foresee potential failures before they occur. A study from McKinsey & Company suggests that organizations employing predictive analytics achieve up to a 20% reduction in maintenance costs and increase equipment availability by 10-15%. By focusing on the right metrics and employing continuous improvement strategies, businesses can significantly enhance the reliability and lifespan of their liquid pump systems, ultimately driving operational excellence.

Exploring Future Trends in Liquid Pump Design and Industrial Applications

The landscape of liquid pump design is undergoing a significant transformation, driven by advancements in technology and the growing demand for energy-efficient solutions. Future trends indicate a strong focus on automation and smart integration, where pumps are not just mechanical devices but part of a larger interconnected system. This shift enables real-time monitoring, predictive maintenance, and adaptive control, enhancing operational efficiency in various industrial applications.

Smart sensors and IoT technology empower users to optimize processes, reduce downtime, and minimize energy consumption—key factors in today’s competitive marketplace.

Another notable trend is the proliferation of sustainable designs that prioritize environmental impact. Manufacturers are increasingly exploring materials and technologies that reduce waste and improve recyclability. Innovations such as magnetic drive pumps and advanced seal technology help decrease leakage and enhance the reliability of pumps in critical applications. Furthermore, the adaptability of pumps for diverse fluids, including corrosive and viscous materials, is being prioritized to expand their applicability across industries like pharmaceuticals, food processing, and wastewater management. By embracing these cutting-edge trends, liquid pumps are set to play a pivotal role in driving industrial efficiency and performance in the years to come.

Related Posts

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

How to Maximize Efficiency in Your Solar Pump System with Latest Technology Innovations

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.