How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

In the realm of fluid transfer, the performance and efficiency of the diaphragm pump play a critical role in various industrial applications. As industries strive for greater productivity and reduced operational costs, understanding how to optimize diaphragm pump performance becomes essential. This guide aims to provide actionable insights into maximizing the efficiency of diaphragm pumps, focusing on key factors such as pump selection, maintenance practices, and operational strategies. By embracing best practices and innovative techniques, operators can not only enhance the reliability of their fluid transfer systems but also achieve significant improvements in energy consumption and overall output. Whether in chemical processing, water treatment, or food production, mastering the efficiency of diaphragm pumps is crucial for achieving optimal performance and ensuring sustainable operations.

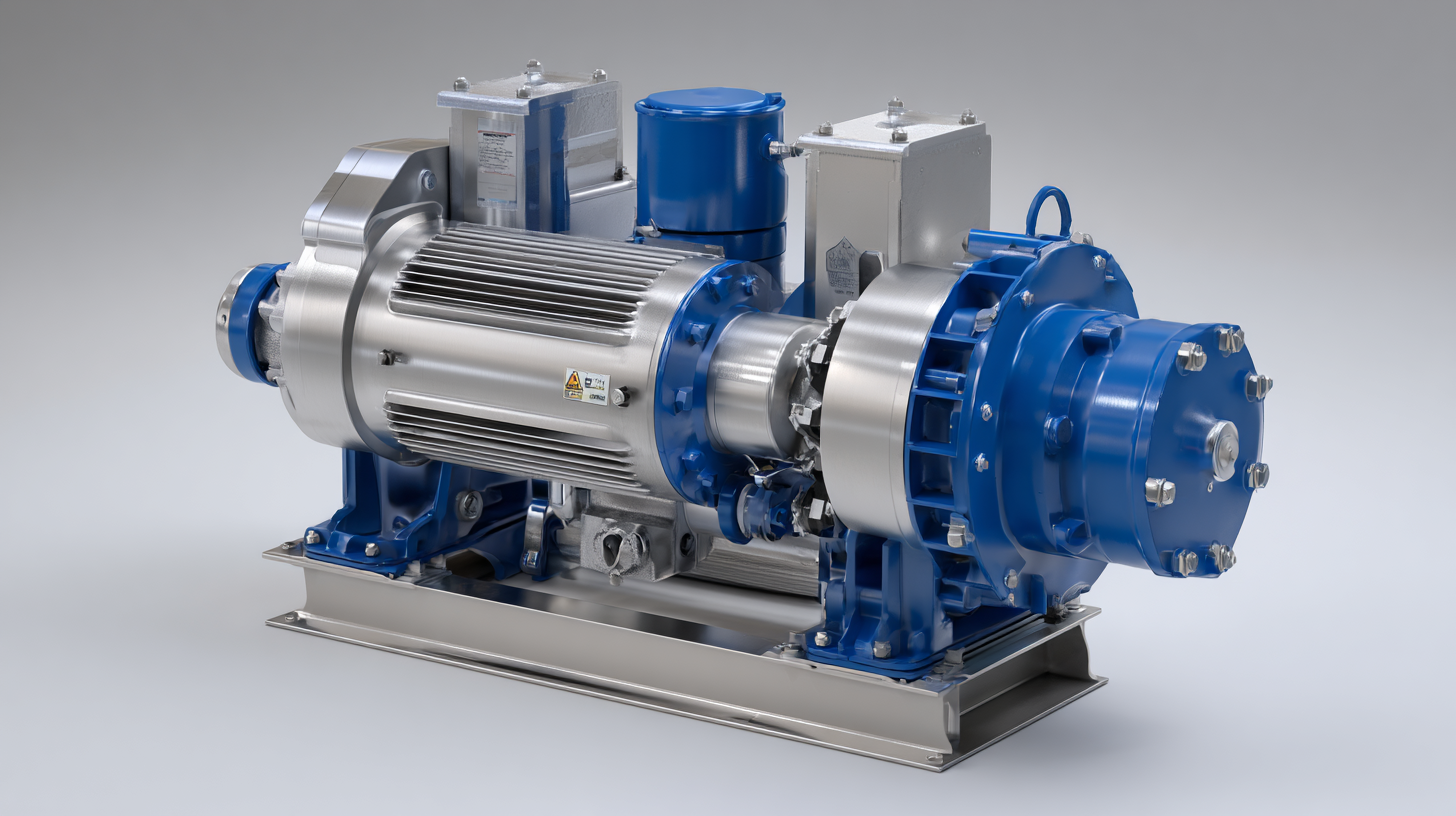

Understanding the Mechanics of Diaphragm Pumps for Fluid Transfer

Diaphragm pumps are essential in various industries for their efficiency and reliability in fluid transfer applications. These pumps operate on a simple principle: they utilize a flexible diaphragm that moves up and down to create a vacuum that draws fluid into the chamber and then forces it out. According to a recent report by Grand View Research, the global diaphragm pump market size was valued at USD 3.99 billion in 2022 and is expected to expand at a CAGR of 3.5% from 2023 to 2030. This growth highlights the increasing demand for efficient and effective fluid management solutions.

Understanding the mechanics of diaphragm pumps is crucial for optimizing their performance. The key components include the diaphragm, the valve system, and the pump body. Variations in diaphragm materials, such as PTFE or elastomers, significantly affect the pump's compatibility with different fluids, including corrosive substances. A study published in the Journal of Fluids Engineering emphasizes that proper pump selection based on fluid properties can enhance operational efficiency by up to 40%. By maintaining the right balance between pump speed and fluid viscosity, operators can significantly reduce energy consumption while ensuring consistent flow rates, thus maximizing overall efficiency in fluid transfer processes.

Fluid Transfer Efficiency with Diaphragm Pumps

This chart illustrates the efficiency levels of diaphragm pumps at different flow rates. As shown, medium flow rates provide the highest efficiency, while low and high flow rates exhibit varying efficiencies in fluid transfer operations.

Identifying Key Factors Influencing Pump Efficiency and Performance

To maximize efficiency in fluid transfer with diaphragm pumps, it is essential to identify and understand the key factors influencing their performance. These factors can include the design and material of the diaphragm, the configuration of the pump system, and operational parameters such as pressure and flow rates. Recent studies on various pump technologies reveal that enhancing the design can significantly improve volumetric efficiency, thereby optimizing fluid delivery in industrial applications. For instance, the incorporation of advanced materials and innovative designs, like optimized impellers, can lead to enhanced performance under varying operational conditions.

Additionally, condition monitoring technologies, including sensorless systems, play a crucial role in diagnosing pump performance. By continuously monitoring operational parameters without the need for traditional sensors, potential performance issues can be identified swiftly, allowing for timely interventions. The integration of machine learning techniques into performance monitoring programs can further refine predictions about pumps' operational efficiency, identifying trends and anomalies that can inform maintenance schedules. Addressing these interconnected factors not only improves the efficiency of diaphragm pumps but also promotes more sustainable fluid transfer processes across various industries.

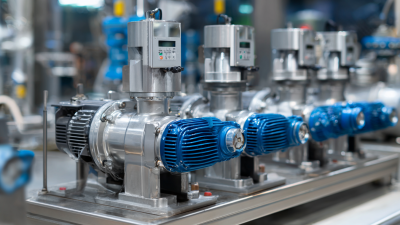

Best Practices for Installation and Setup of Diaphragm Pumps

When installing and setting up diaphragm pumps, ensuring a smooth and efficient operation starts with proper positioning. It’s essential to position the pump close to the fluid source to minimize suction lift and reduce the risk of cavitation. The mounting surface should be solid and free from vibrations, as excess movements can affect the pump's performance. Additionally, ensure that the pump is installed in a way that allows easy access for future maintenance and inspections.

Another critical aspect of setup involves the piping configuration. Use the proper diameter and length of pipes to minimize friction loss and achieve optimal flow rates. Incorporate suitable valves and fittings to avoid turbulence, which can hamper pump efficiency. Before finalizing the installation, double-check all connections to prevent leaks and ensure that the fluid is compatible with the pump materials. Lastly, conducting a thorough system test after installation can help identify any issues early on, ensuring that the diaphragm pump operates at its best from the start.

Regular Maintenance Tips to Enhance Diaphragm Pump Longevity

To maximize the efficiency of diaphragm pumps in fluid transfer applications, regular maintenance is essential. By adhering to a structured maintenance schedule, users can significantly enhance the longevity and performance of their diaphragm pumps.

One crucial tip is to routinely check and replace the wear components, such as diaphragms and valves. These parts endure the most stress during operation, and any signs of wear or damage can lead to decreased performance and potential pump failure. Inspecting these components every few months, or more frequently if the pump operates continuously, can prevent costly downtimes.

Additionally, ensuring that the pump is adequately lubricated can vastly improve its operational life. Use lubricant recommended by the manufacturer and avoid over-lubrication, which can attract contaminants and hinder performance. Finally, a regular inspection of the connections and fittings can detect leaks early, maintaining system efficiency and preventing unnecessary losses in fluid transfer. Through these simple yet effective maintenance practices, you can ensure your diaphragm pump operates at its best for years to come.

Optimizing Operational Conditions for Peak Performance in Pumping Systems

To achieve optimal performance in diaphragm pump systems, it is crucial to optimize operational conditions. Key factors such as fluid viscosity, temperature, and pump speed play significant roles in the efficiency of fluid transfer. By understanding the characteristics of the fluid being pumped, operators can select the appropriate diaphragm material and pump configuration to minimize wear and ensure durability, thereby enhancing longevity and reducing downtime.

Additionally, maintaining consistent operating conditions is essential for peak pump performance. Implementing regular maintenance schedules and monitoring system parameters can prevent common issues such as cavitation and pulsation, which can lead to inefficient operation. Utilizing sophisticated control systems that adjust parameters in real-time can further maximize efficiency by ensuring that the pump operates within its optimal range. By focusing on these operational strategies, users can significantly improve the fluid transfer process, ensuring reliability and efficiency in various applications.

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

| Parameter | Optimal Value | Impact on Efficiency |

|---|---|---|

| Fluid Viscosity | 10 - 150 cP | Maintains optimal flow rate and reduces wear |

| Pump Speed | 100 - 300 RPM | Achieves desired flow without cavitation |

| Suction Lift Height | Less than 5 ft | Reduces risk of air entering the system |

| Temperature | Up to 120 °C | Ensures integrity of pump materials |

| Pumping Cycle Duration | Continuous with breaks | Prevents overheating and extends pump life |

| Maintenance Frequency | Monthly checks | Enhances performance and reliability |

Related Posts

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

How to Choose the Right Electric Pumps for Your Business Needs

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.