Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

In today's rapidly evolving industrial landscape, efficiency is paramount, and the adoption of advanced technologies is crucial for optimizing processes. One such innovation is the electric chemical injection pump, which has been instrumental in enhancing operational performance across various sectors, including oil and gas, water treatment, and chemical manufacturing. According to a report by MarketsandMarkets, the global market for chemical injection pumps is projected to reach USD 5.2 billion by 2025, with electric variants driving significant growth due to their superior precision, reliability, and lower environmental impact. Companies that leverage electric chemical injection pumps can achieve not only improved efficiency but also reduced operational costs and minimized downtime, ultimately leading to a more sustainable industrial operation. Emphasizing these benefits, this article will explore practical tips and solutions to maximize efficiency in industrial processes using these advanced pumping systems.

Maximizing Pump Performance: Understanding the Role of Electric Chemical Injection Pumps in Industry

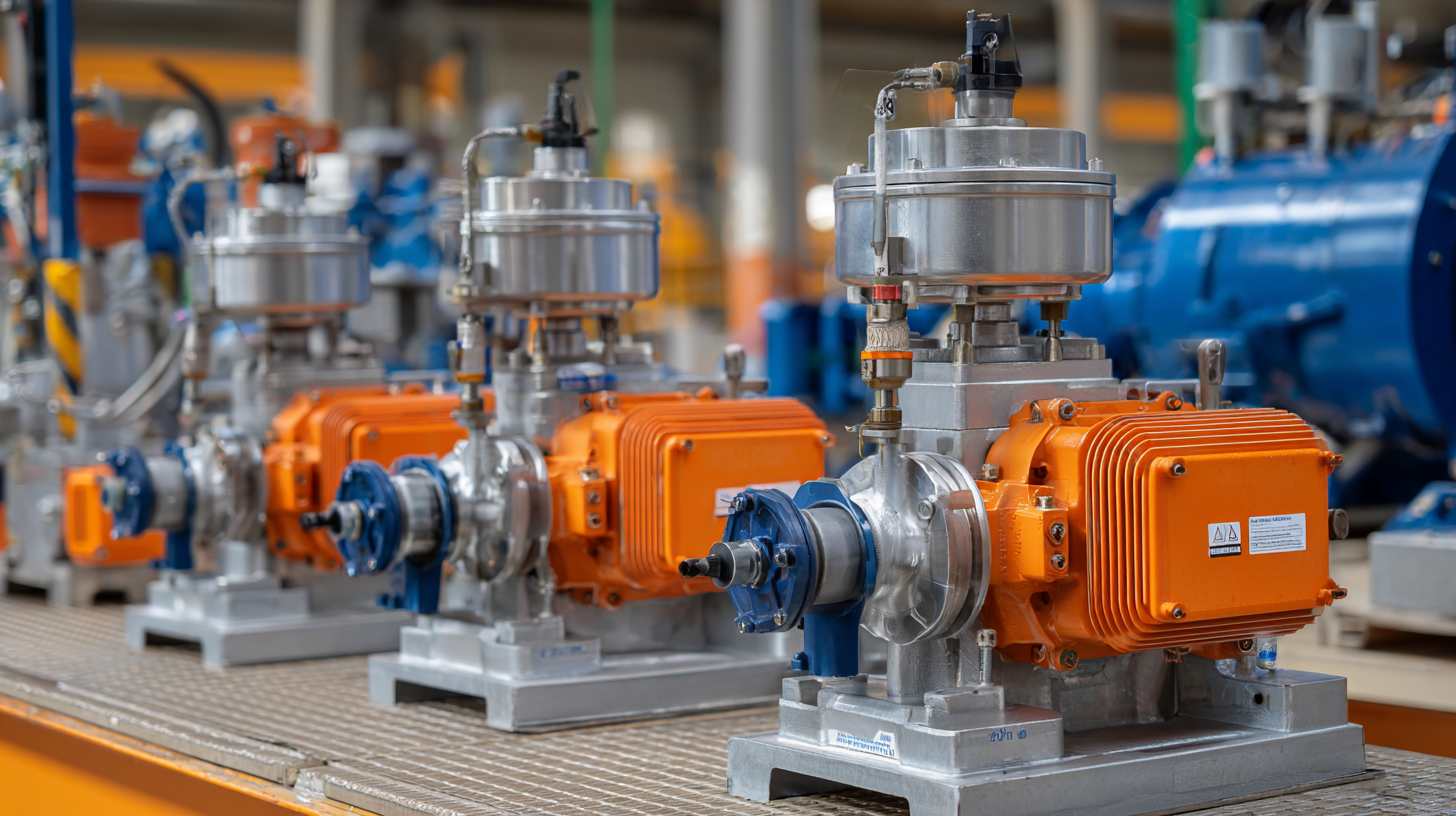

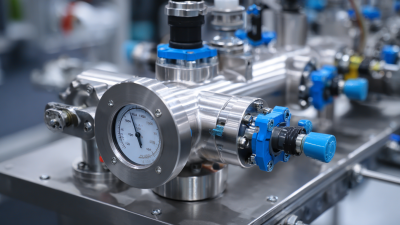

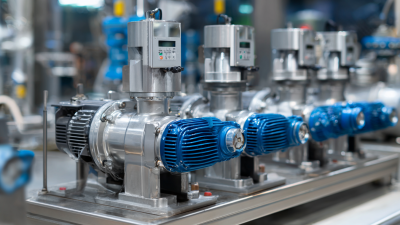

Electric chemical injection pumps play a crucial role in enhancing operational efficiency within various industrial processes. These pumps utilize advanced technology to provide precise control over fluid delivery, which is essential in industries that require accurate dosing of chemicals, such as water treatment, oil and gas, and pharmaceuticals. By maintaining optimal flow rates and pressures, electric chemical injection pumps minimize waste and ensure that systems function smoothly without interruptions.

The technology behind electric chemical injection pumps also allows for real-time monitoring and adjustments, which further boosts their performance. This adaptability enables industries to respond swiftly to changes in demand or operating conditions, all while maintaining stringent safety standards. Additionally, the integration of these pumps with smart systems contributes to improved data collection and analysis, facilitating predictive maintenance and reducing downtime. Ultimately, the implementation of electric chemical injection pumps leads to not only enhanced efficiency but also significant cost savings across industrial operations.

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

| Parameter | Description | Value |

|---|---|---|

| Flow Rate | The volume of fluid pumped per unit time | 150 L/h |

| Max Pressure | The highest pressure the pump can handle | 10 bar |

| Power Consumption | Energy used by the pump during operation | 300 W |

| Material Compatibility | Materials that can be safely pumped | Corrosive Chemicals, Water |

| Control System | Type of control used for operation | PLC Integrated |

| Maintenance Interval | Time between required maintenance checks | 1 Month |

Key Specifications: Analyzing the Efficiency Metrics of Advanced Electric Pumps in Process Automation

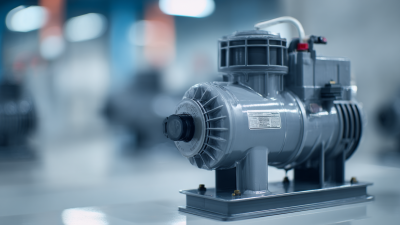

Advanced electric chemical injection pumps have revolutionized industrial processes by offering significant improvements in efficiency metrics. According to the latest report from the Chemical Engineering Journal, advanced electric pumps can achieve operational efficiencies exceeding 95%, which starkly contrasts with traditional mechanical pumps that often operate between 70-85%. This enhancement not only reduces energy consumption but also minimizes the carbon footprint of industrial operations, aligning with the increasingly rigorous environmental regulations.

In terms of reliability and precision, advanced electric pumps significantly outperform their predecessors. Data from the International Society for Automation indicates that these pumps can maintain flow rates within ±1% accuracy, ensuring optimal process control. Moreover, the lifespan of these pumps is reportedly increased by up to 40% due to their robust design and advanced materials, reducing maintenance costs and downtime. Moreover, corporations that have integrated these advanced systems have reported a 25% decrease in operational costs, showcasing the dual benefits of sustainability and economic viability. This data underscores the impact of technology in enhancing process automation and energy efficiency in industrial sectors.

Reducing Operational Costs: How Improved Delivery Accuracy of Injection Pumps Enhances Profitability

The operational efficiency of industrial processes is significantly enhanced by the deployment of advanced electric chemical injection pumps. By providing precise delivery accuracy, these pumps reduce waste and ensure optimal use of resources. According to a report by the Global Chemical Injection Pumps Market Analysis, achieving a delivery accuracy of over 98% can lower operational costs by nearly 20%, illustrating a direct correlation between pump efficiency and profitability.

Furthermore, industrial sectors such as oil and gas have reported savings of up to $5 million annually by implementing state-of-the-art injection technology. This advanced methodology allows for improved control over chemical dosages, leading to fewer errors and a decrease in excess spending on unwanted materials. Additionally, the American Society of Mechanical Engineers notes that an increase in pump performance can directly impact overall equipment effectiveness (OEE), driving both productivity and profitability in competitive markets. As industries strive for more sustainable operations, the adoption of precise electric chemical injection pumps will be vital in achieving notable cost reductions and enhancing profit margins.

Maximizing Efficiency in Industrial Processes with Advanced Electric Chemical Injection Pumps

This bar chart illustrates the percentage of cost reduction achieved by industries utilizing advanced electric chemical injection pumps across four quarters. The increased delivery accuracy of these pumps contributes significantly to improving operational efficiency and profitability.

Industry Applications: Exploring the Use Cases of Electric Chemical Injection Pumps Across Various Sectors

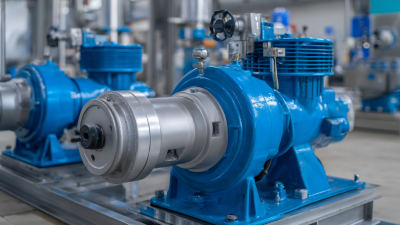

Electric chemical injection pumps are increasingly becoming vital tools in various industrial sectors due to their superior efficiency and precision in chemical management. One prominent application can be found in the water treatment industry, where these pumps ensure accurate dosing of chemicals for disinfection and pH adjustment. By utilizing electric chemical injection pumps, facilities can maintain optimal water quality while minimizing chemical waste, ultimately leading to safer and more sustainable operations.

In the oil and gas sector, electric chemical injection pumps play a crucial role in enhancing the extraction process. They are used for the precise injection of chemical agents that aid in crude oil recovery, such as drag-reducing agents and surfactants. This not only maximizes the efficiency of the extraction process but also reduces the environmental impact by ensuring that harmful chemicals are precisely managed and contained. Other industries, such as agriculture and pharmaceuticals, also reap benefits from these advanced pumps, which facilitate the delicate balance of chemical application for fertilizers and biochemicals, further highlighting their versatility across various applications.

Future Innovations: Trends and Developments Shaping the Evolution of Electric Chemical Injection Pump Technology

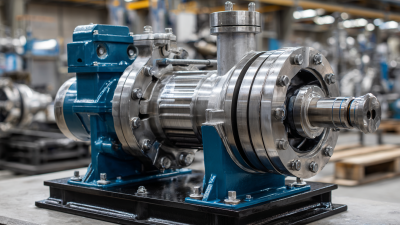

The landscape of electric chemical injection pump technology is rapidly transforming, driven by advancements that promise to enhance industrial efficiency and sustainability. As industries increasingly prioritize environmental responsibility, innovations such as smart sensors and IoT integration are at the forefront. These technologies enable real-time monitoring and precise control of chemical injection processes, significantly reducing waste and ensuring optimal performance. The ability to gather and analyze data remotely is revolutionizing how facilities manage their operations, promoting more efficient resource usage.

Additionally, the development of advanced materials and design approaches is reshaping the construction of electric chemical injection pumps. Lightweight materials enhance durability while reducing energy consumption, contributing to more sustainable practices. Furthermore, the incorporation of artificial intelligence and machine learning algorithms allows for predictive maintenance, minimizing downtime and extending the lifespan of the equipment. As these trends continue to evolve, we can expect a more robust and efficient future for electric chemical injection pumps, aligning with the broader goals of industry 4.0 and sustainable manufacturing.

Related Posts

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

Understanding the Importance of Chemical Metering Pumps in Industrial Applications

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

How to Choose the Right Electric Pumps for Your Business Needs

-

What Makes a Plunger Pump Different from Other Pump Types

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.