How to Optimize Your Injection Pumps for Maximum Efficiency and Performance

Optimizing injection pumps is critical for enhancing overall system performance and efficiency, particularly in sectors such as oil and gas and water treatment. According to a recent report by the International Energy Agency, efficient pump operation can improve energy savings by up to 20%, translating to significant cost reductions and sustainability benefits. Furthermore, the Hydraulic Institute emphasizes that properly maintained injection pumps can operate at up to 95% efficiency, underscoring the importance of regular optimization practices.

As industries increasingly prioritize performance and productivity, understanding the intricacies of injection pump settings, maintenance routines, and operational adjustments becomes essential. This guide will delve into strategies to maximize the efficiency and performance of injection pumps, ensuring they not only meet but exceed operational standards in a competitive environment.

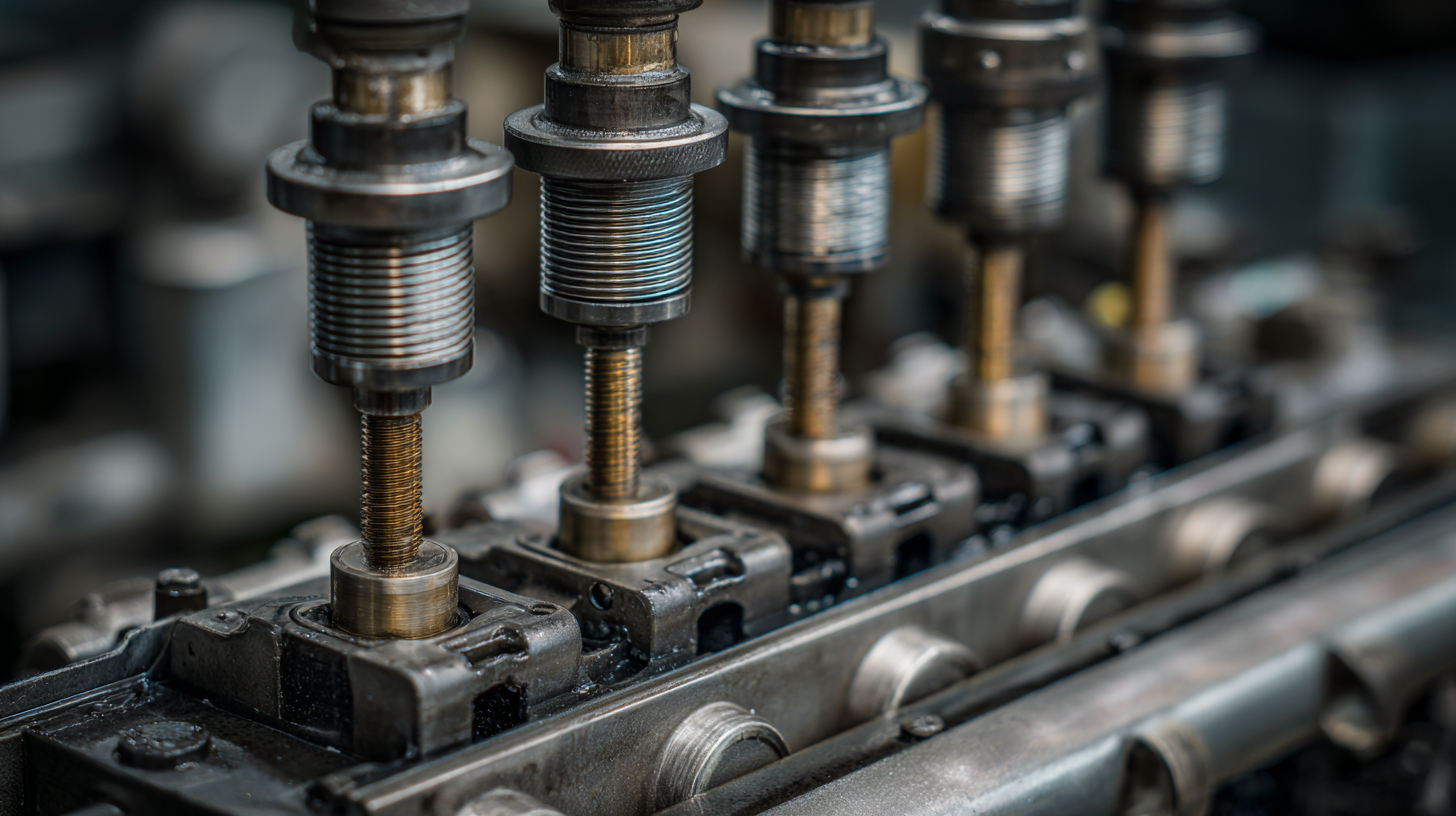

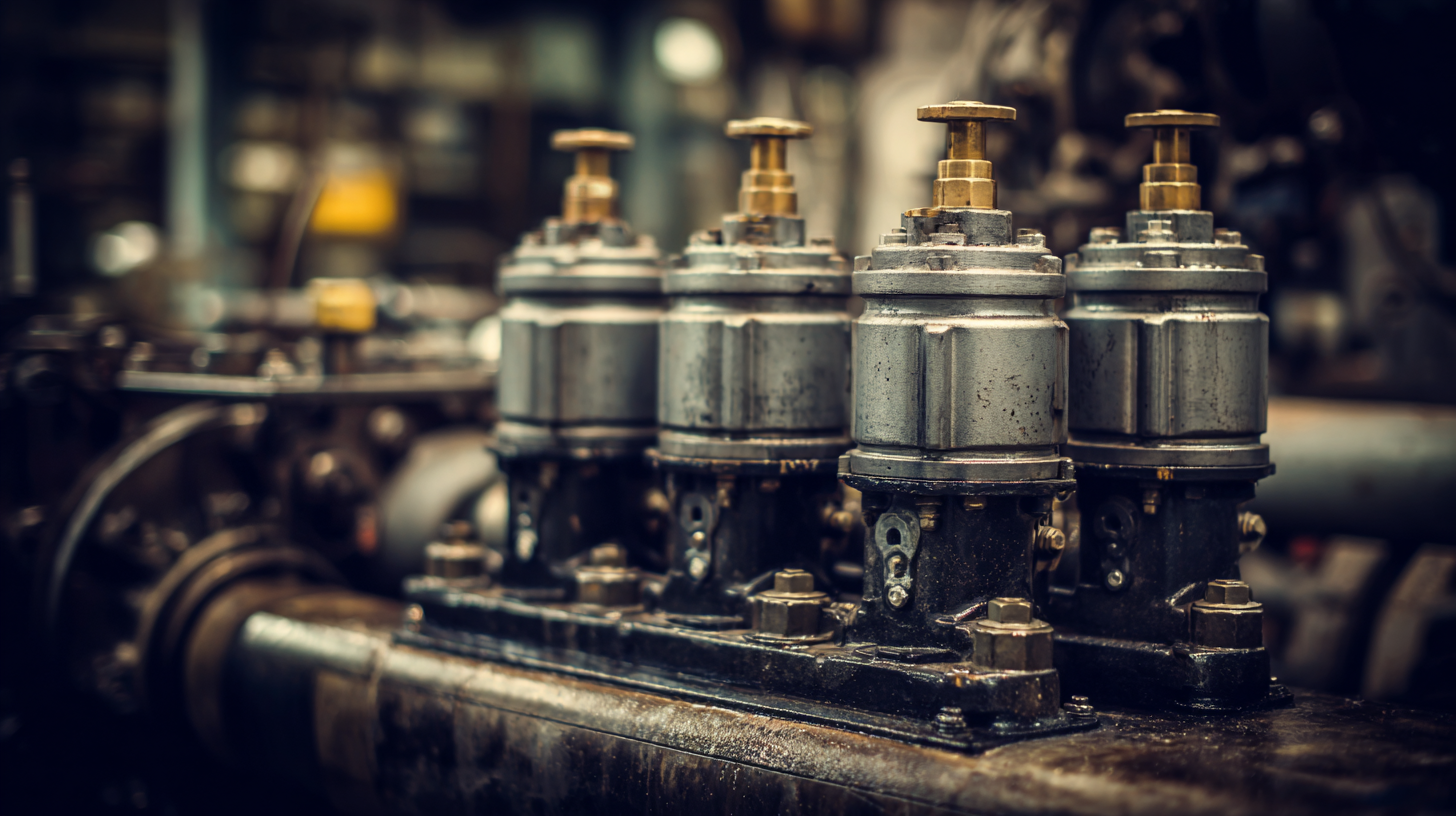

Understanding Injection Pump Types and Their Applications for Optimal Selection

When selecting injection pumps for optimal performance, understanding the various types available and their specific applications is crucial. There are several categories of injection pumps, including gear pumps, diaphragm pumps, and screw pumps, each with unique characteristics that make them suitable for different scenarios.

Gear pumps, for instance, are known for their durability and efficiency in handling viscous fluids, making them a popular choice in oil and chemical industries. On the other hand, diaphragm pumps excel in providing precise flow rates and are often employed in water treatment and agricultural applications.

Gear pumps, for instance, are known for their durability and efficiency in handling viscous fluids, making them a popular choice in oil and chemical industries. On the other hand, diaphragm pumps excel in providing precise flow rates and are often employed in water treatment and agricultural applications.

Choosing the right injection pump requires an assessment of the fluid properties, pressure requirements, and desired flow rates. It is essential to match the pump type with the application to ensure not only optimal performance but also long-term reliability.

For high-pressure applications, screw pumps can provide the necessary power and consistency, while for low-pressure needs, gear or diaphragm pumps might be more appropriate. By carefully evaluating the specific requirements of your system and understanding the strengths of each pump type, you can optimize injection pump selection for maximum efficiency and performance.

Key Performance Indicators for Evaluating Injection Pump Efficiency

When evaluating injection pump efficiency, key performance indicators (KPIs) play a crucial role in identifying areas for optimization. The most important KPIs include flow rate consistency, energy consumption, and maintenance frequency. Monitoring these metrics can help businesses adjust their operational strategies to enhance pump performance.

**Tips:** Regularly track flow rate consistency to ensure that the pump meets the required specifications. Implementing automated monitoring systems can provide real-time data, allowing for prompt adjustments. Additionally, analyzing energy consumption patterns can reveal inefficiencies within the system, leading to potential savings and reduced environmental impact.

Another vital KPI is the Mean Time Between Failures (MTBF). A high MTBF indicates reliability, while a low value suggests frequent maintenance needs. By conducting regular inspections and maintenance at predetermined intervals, operators can increase MTBF and consequently pump efficiency.

**Tips:** Establish a preventive maintenance schedule based on the manufacturer's recommendations and historical performance data. This proactive approach not only prolongs the lifespan of the equipment but also ensures consistent performance, reducing downtime and associated costs.

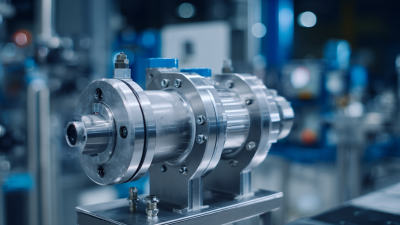

Factors Affecting Injection Pump Performance: Maintenance and Calibration Insights

Injection pump performance is influenced by various factors that underscore the importance of proper maintenance and calibration. Regular maintenance schedules are crucial; according to industry reports, systems experiencing consistent upkeep can improve their operational efficiency by up to 20%. This not only enhances performance but also extends the overall lifespan of the equipment. Key components such as filters, seals, and calibration settings must be inspected and optimized regularly to prevent performance degradation.

Calibration plays a pivotal role as well. Research indicates that improperly calibrated pumps can lead to energy losses of approximately 15-30%. Ensuring accurate calibration prevents excessive fuel consumption and reduces emissions, aligning with ongoing trends in decarbonization and sustainability. Additionally, advanced process controls can be integrated, maximizing the efficiency of energy and material usage, which is becoming increasingly vital in industrial settings.

**Tips:**

1. Implement a strict maintenance schedule to catch potential issues early and ensure optimal performance.

2. Utilize advanced monitoring systems to facilitate real-time calibration adjustments for your injection pumps.

3. Train your personnel on the latest maintenance techniques and technologies to keep your systems running efficiently.

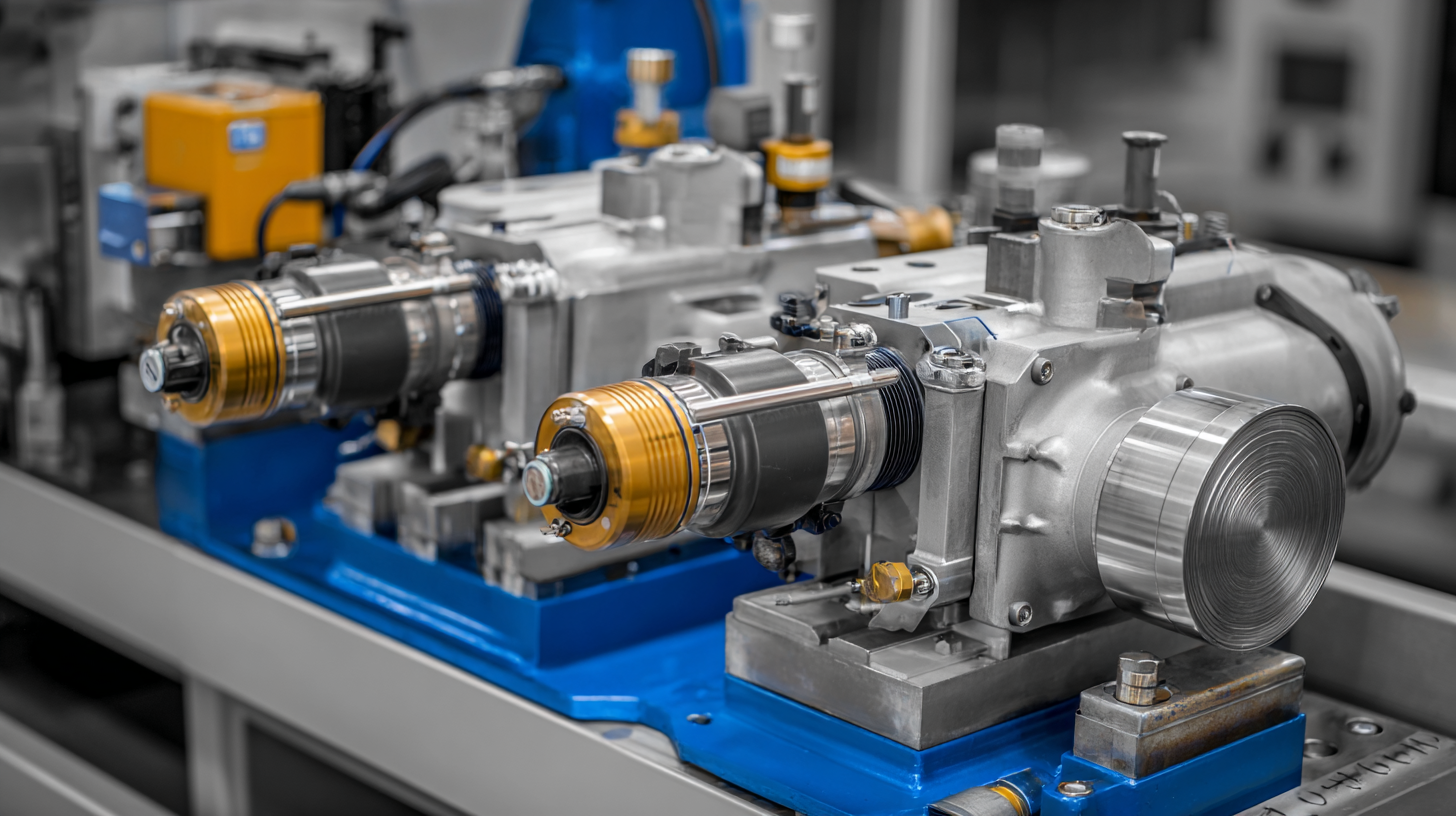

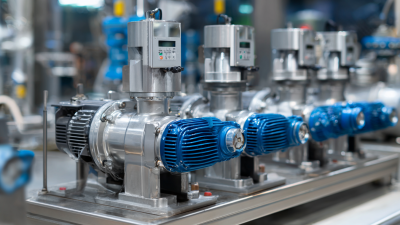

Advanced Technologies in Injection Pumps: Innovations for Enhanced Efficiency

Recent innovations in injection pump technology are focused on enhancing efficiency through advanced system integration and automation. These developments align closely with broader trends in various sectors, such as geothermal energy utilization, where smart systems are being deployed for sustainable heating and cooling solutions. By integrating sensors and data analytics, modern injection pumps can adjust their operations in real-time to optimize performance while minimizing energy consumption.

Moreover, the introduction of advanced materials and design principles in injection pump manufacturing is contributing to enhanced longevity and reduced maintenance costs. The ongoing research into hydraulic pump technologies mirrors this trend, emphasizing the importance of versatility and adaptability in industrial applications. As industries increasingly prioritize sustainability, innovations in injection pumps and hydraulic systems are essential for achieving operational excellence and meeting growing efficiency demands.

Injection Pump Efficiency Optimization

Best Practices for System Integration to Maximize Injection Pump Effectiveness

Optimizing injection pumps is critical for achieving maximum efficiency and performance, particularly through effective system integration. Best practices begin with understanding the specific needs of the installed environment. For example, integrating renewable energy sources, such as solar or wind, can significantly enhance operational effectiveness. According to recent studies, hybrid renewable energy water pumping systems (HREWPS) show promise in maximizing efficiency by adapting to fluctuating environmental conditions while minimizing energy costs. Implementing such systems can help reduce reliance on traditional energy sources, creating a more sustainable operation.

Furthermore, the integration of advanced technologies like artificial intelligence (AI) contributes to improved performance in injection pump systems. AI can optimize operational parameters dynamically, ensuring that pumps are running at peak efficiency despite changes in demand or system conditions. Recent reports indicate that facilities applying smart system integration techniques have observed performance improvements of up to 30%. As industries shift towards greater sustainability and efficiency, adopting these best practices will be vital for maximizing the effectiveness of injection pumps in various applications.

Related Posts

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

How to Choose the Right Electric Pump for Your Specific Needs

-

Understanding the Types of Fluid Pumps in Industrial Applications with Key Market Insights

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.