What Makes a Plunger Pump Different from Other Pump Types

In the diverse world of industrial pumping systems, understanding the unique characteristics of a plunger pump is crucial for optimizing operational efficiency. Unlike centrifugal pumps, which rely on rotational energy and fluid dynamics to move liquids, plunger pumps utilize linear motion to generate pressure, making them ideal for high-viscosity fluids and high-pressure applications. According to a recent market report by Research and Markets, the global plunger pump market is projected to witness a robust growth rate of approximately 5% annually through 2026, driven by increasing demand across various sectors, including oil and gas, water treatment, and chemical processing. The plunger pump's ability to handle fluctuating flow rates and maintain consistent performance under demanding conditions positions it as a vital component in many industrial processes, setting it apart from other pump types. Understanding these distinctive features is key for engineers and operators when selecting the appropriate pump for specific applications.

Key Characteristics of Plunger Pumps Compared to Other Pumps

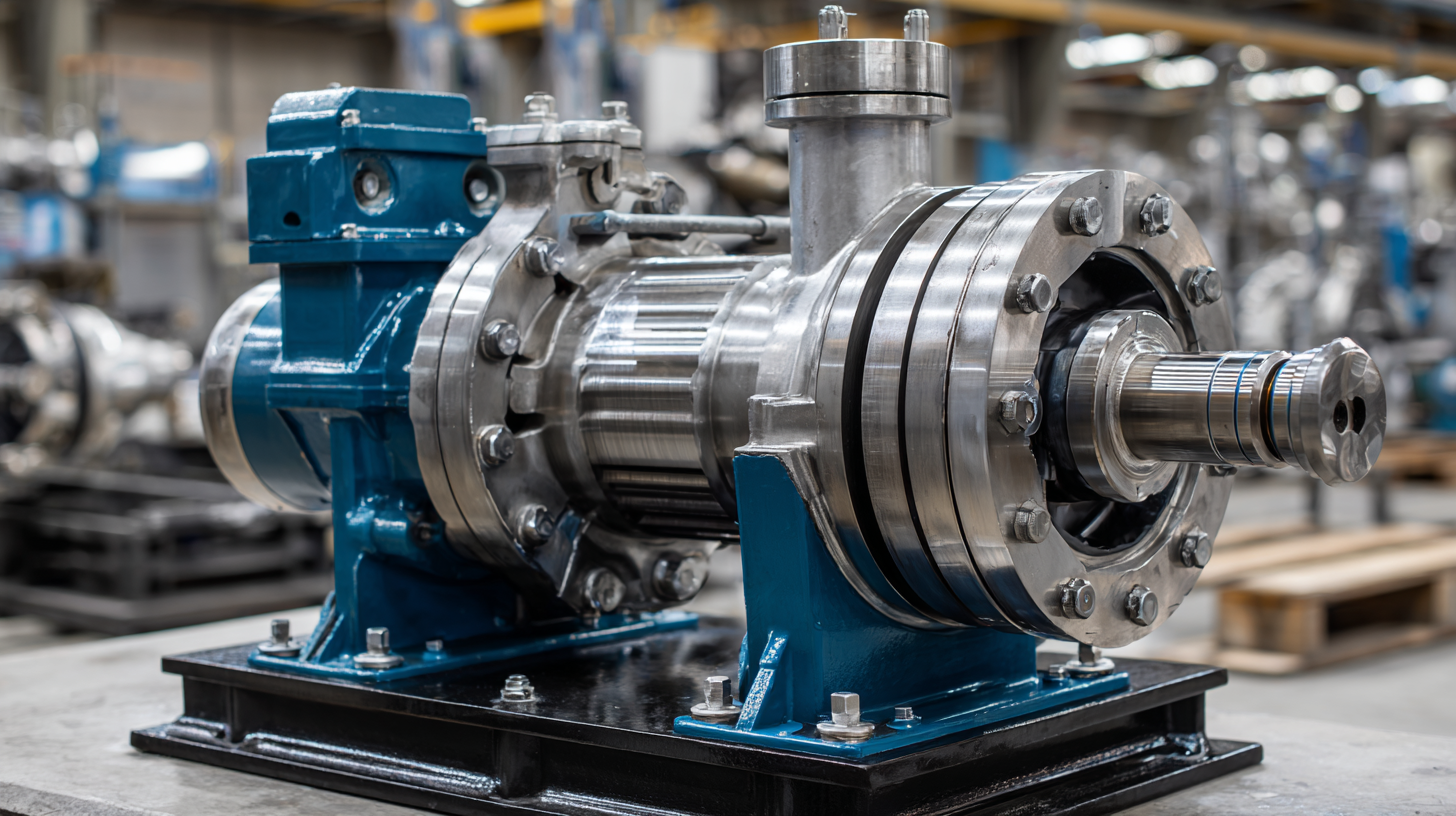

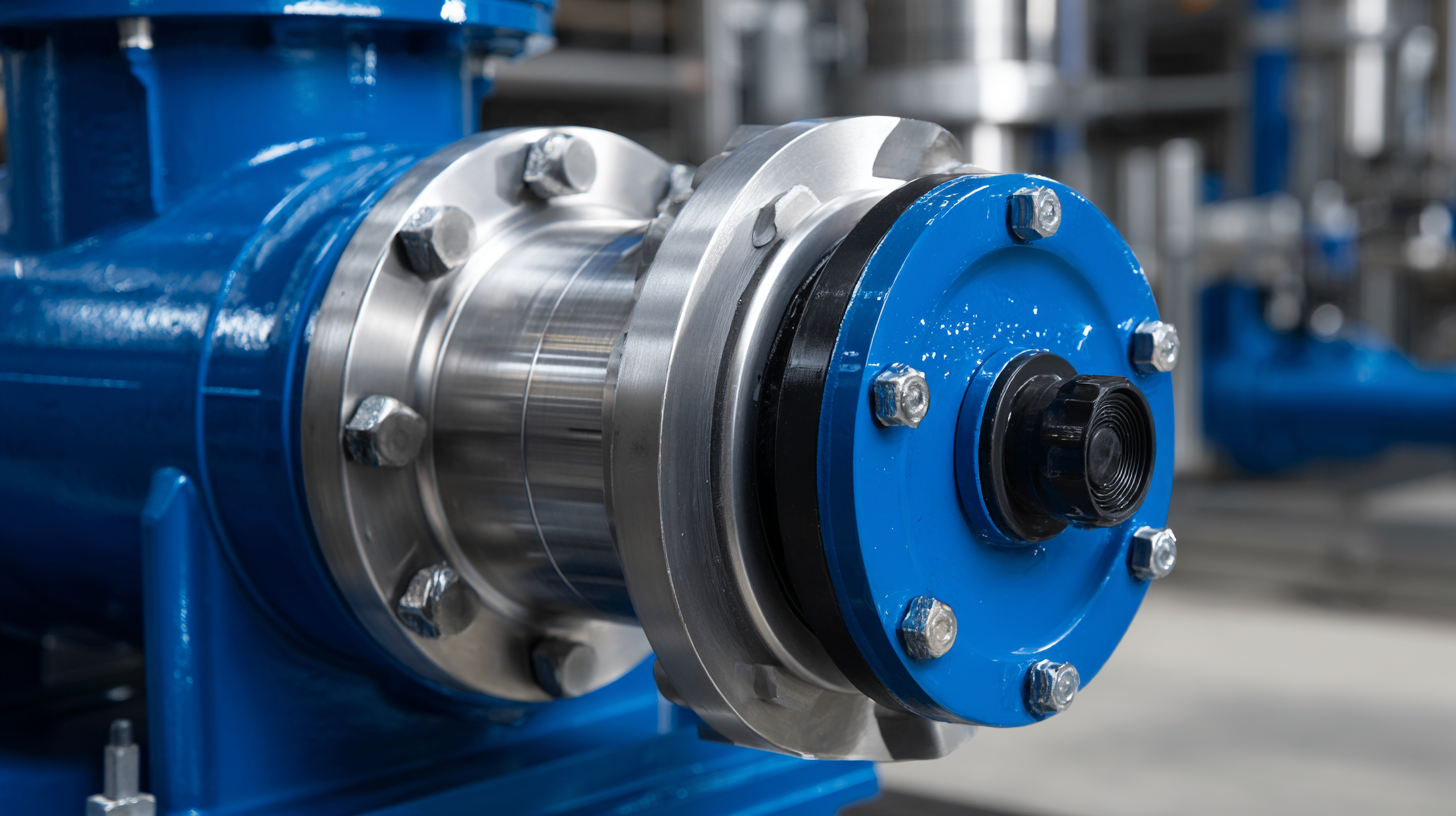

Plunger pumps are distinct from other pump types due to their unique design and operational principles. Unlike centrifugal pumps that rely on rotational energy to move fluid, plunger pumps utilize a reciprocating plunger to displace liquid. This mechanism allows for higher pressure outputs and the ability to handle viscous fluids, making them particularly suitable for applications demanding high pressure and consistency.

Another key characteristic of plunger pumps is their adjustable flow rate capabilities. By changing the stroke length or speed of the plunger, operators can fine-tune the flow according to their specific needs. Additionally, plunger pumps are known for their durability and performance in extreme conditions, as they can withstand abrasive materials, high temperatures, and varying chemical compositions without significant wear. This resilience makes them a preferred choice for industries such as oil and gas, chemical manufacturing, and wastewater treatment, where reliability and efficiency are critical.

Understanding the Mechanism Behind Plunger Pump Operation

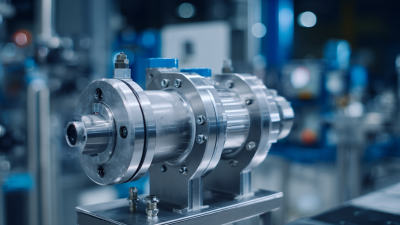

Plunger pumps stand out from other pump types primarily due to their unique operational mechanism. Unlike centrifugal pumps that rely on rotational energy to move fluids, plunger pumps utilize a reciprocating motion, where a plunger moves back and forth within a cylinder to create pressure and facilitate flow. This design allows for precisely controlled fluid delivery, making plunger pumps particularly advantageous in applications requiring high pressure and low flow rates.

Understanding the mechanism of plunger pumps reveals their advantages in managing issues such as cavitation, which is a significant concern in other pumps, such as axial piston pumps. Cavitation occurs when vapor bubbles form in low-pressure areas, leading to flow reduction and potential damage. The robust design of plunger pumps, combined with advancements in technology such as dual stacking mechanisms, enhances their operational efficiency by providing increased power density and mitigating cavitation effects. This innovation reflects a broader trend in pump design, where maintaining fluid integrity while minimizing shear stress is critical, especially in applications involving sensitive materials like monoclonal antibodies.

Common Applications for Plunger Pumps in Various Industries

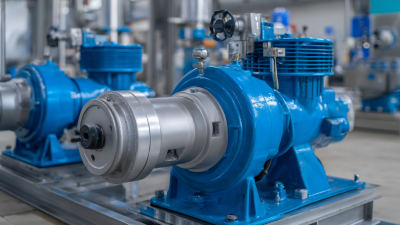

Plunger pumps are versatile devices renowned for their ability to handle high-pressure applications across different industries. One of their most common applications is in the oil and gas sector, where they facilitate the transportation of viscous fluids and crude oil. Their design allows them to withstand extreme pressures, ensuring efficient extraction and transfer processes even in challenging environments. This capability makes them essential for maintaining the flow of resources without compromising safety or efficiency.

In the chemical manufacturing industry, plunger pumps are frequently utilized for dosing and transferring corrosive liquids. Their robust construction and precise flow control make them ideal for handling chemicals that require accurate metering, thereby reducing the risk of contamination or spillage. Similarly, in the food and beverage sector, these pumps play a crucial role in transporting thick liquids and slurries while adhering to strict hygiene standards. Their ability to operate under varying conditions further enhances their reliability, making plunger pumps a preferred choice for various industrial applications.

Advantages of Using Plunger Pumps Over Other Pump Types

Plunger pumps stand out in the pump market primarily due to their efficiency and capability to handle high-pressure applications. According to a report by Grand View Research, the global positive displacement pump market, which includes plunger pumps, is projected to reach $24.40 billion by 2025, reflecting a growing demand for precise fluid transfer in various industries. One of the significant advantages of plunger pumps is their ability to maintain a consistent flow rate even against varying system pressures, making them ideal for applications in oil and gas, chemical processing, and wastewater management.

Another key benefit of plunger pumps is their versatility in dealing with high-viscosity fluids and slurries. Unlike centrifugal pumps, which may struggle with thick liquids, plunger pumps can effectively handle a wide range of fluid types, as evidenced by a study from Research and Markets, which highlights that demand for heavy-duty pumping solutions is on the rise. Additionally, their robust construction allows for easier maintenance and longer operational life, which ultimately leads to cost savings for businesses. This combination of high efficiency, reliability, and versatility is why plunger pumps are increasingly favored over other pump types in critical industrial applications.

What Makes a Plunger Pump Different from Other Pump Types - Advantages of Using Plunger Pumps Over Other Pump Types

| Feature | Plunger Pumps | Diaphragm Pumps | Gear Pumps | Centrifugal Pumps |

|---|---|---|---|---|

| Pressure Handling | High pressure capabilities | Moderate pressure capabilities | Variable, often lower | Low to moderate |

| Fluid Type Compatibility | Can handle viscous and abrasive fluids | Best for clean liquids | Suitable for low viscosity fluids | Best for clear, clean liquids |

| Efficiency | High efficiency at varying pressures | Efficiency can decrease with wear | Generally efficient for specified tasks | Less efficient at high pressures |

| Maintenance | Requires regular maintenance but robust | Higher maintenance needed | Low maintenance requirement | Minimal maintenance, but wear on impellers |

| Applications | Ideal for high-pressure washing, chemical dosing | Used in medical and food applications | Common in automotive and industrial work | General purpose, lower pressure applications |

Maintenance Tips for Ensuring Optimal Performance of Plunger Pumps

To ensure optimal performance of plunger pumps, regular maintenance is essential. First and foremost, it's crucial to keep the pump clean and free of debris. Regularly inspect the intake and discharge ports for blockages that may hinder flow. Additionally, routine checks on the seals and packing materials should be performed, as worn-out seals can lead to leaks and diminished efficiency. Replacing these components as needed helps maintain the integrity of the pump's operation.

Another vital maintenance tip is to monitor the pump’s lubrication levels. Plunger pumps rely on proper lubrication to minimize friction between moving parts, which prolongs the lifespan of the pump. Using the correct type of lubricant and ensuring it is topped up according to the manufacturer’s specifications can prevent overheating and mechanical failure. Furthermore, it is advisable to regularly review the pump's operational parameters and performance metrics. This ongoing evaluation allows for the early detection of any irregularities, enabling swift corrective actions to maintain peak performance.

Related Posts

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

7 Reasons Why Electric Diaphragm Pumps Are Your Top Choice for Efficient Fluid Management

-

How to Maximize Efficiency in Fluid Transfer with Diaphragm Pumps for Optimal Performance

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.