Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

The evolution of fluid management systems is rapidly transforming industrial processes, with the electric chemical injection pump at the forefront of this revolution. According to recent industry reports, the global market for chemical injection systems is expected to grow from $2.2 billion in 2021 to over $3.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.5%. This surge is driven by the increasing demand for advanced fluid management solutions that enhance efficiency and reduce operational costs. Electric chemical injection pumps offer precise control over chemical dosing, ensuring optimal performance while minimizing environmental impacts.

As industries strive to meet stringent regulatory standards and embrace sustainability, electric chemical injection pumps stand out as a crucial technology for achieving these goals, ultimately reshaping the landscape of fluid management in sectors ranging from oil and gas to water treatment.

Understanding the Importance of Fluid Management in Industrial Processes

Effective fluid management is critical in industrial processes, impacting efficiency, safety, and environmental compliance. According to a report by the International Journal of Chemical Engineering, improper fluid management can lead to a 15% decrease in operational efficiency. This statistic underscores the significance of implementing advanced fluid management solutions, such as electric chemical injection pumps, which offer precise control and reduced waste.

As industries increasingly prioritize sustainability, the role of innovative pumping technologies becomes paramount. By utilizing electric chemical injection pumps, businesses can achieve significant reductions in fluid consumption and improve dosing accuracy, thereby lowering operational costs. Research from the Fluid Power Journal indicates that automating fluid management can improve system reliability by up to 30%, which is essential in maintaining smooth industrial operations.

**Tips:** To enhance your fluid management strategy, regularly monitor fluid levels and quality to prevent contamination. Additionally, consider investing in training for your team to ensure everyone understands the importance of efficient fluid handling. Leveraging real-time monitoring technologies can also provide insights that drive further optimization in your processes.

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps Explained

| Parameter | Value | Importance |

|---|---|---|

| Flow Rate (L/min) | 0-500 | Essential for precise fluid control |

| Operating Pressure (bar) | 0-15 | Influences pump efficiency and reliability |

| Power Consumption (W) | 50-300 | Affects operational costs |

| Material Compatibility | Various chemicals | Crucial for longevity and safety |

| Control Method | Electric | Provides high precision and automation |

| Maintenance Frequency (months) | 6-12 | Ensures operational reliability |

| Integration Capability | IoT-enabled | Enhances monitoring and data collection |

Key Benefits of Electric Chemical Injection Pumps over Traditional Pumps

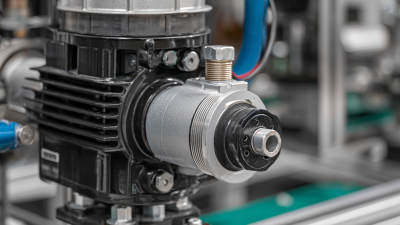

Electric chemical injection pumps are fundamentally transforming fluid management across various industries. One of the most significant advantages is their precision and accuracy. According to a report by Frost & Sullivan, electric pumps can achieve flow rate accuracies of up to ±1%, which is a substantial improvement over the ±5% accuracy typically found in traditional pneumatic pumps. This enhanced precision not only improves product quality but also reduces the risk of over- or under-dosing, leading to significant cost savings in materials and potential penalties from regulatory bodies.

Moreover, the operational efficiencies of electric chemical injection pumps are noteworthy. A study by the International Energy Agency (IEA) highlights that electric pumps can reduce energy consumption by up to 30% compared to traditional pumps, primarily due to their ability to operate at lower speeds while maintaining high performance. This reduction in energy usage translates to decreased operational costs and a lower environmental footprint, making electric pumps an appealing choice for companies striving for sustainability. The combination of accuracy, efficiency, and sustainability positions electric chemical injection pumps as a pivotal advancement in fluid management technologies.

Technological Innovations Driving the Future of Electric Chemical Injection Pumps

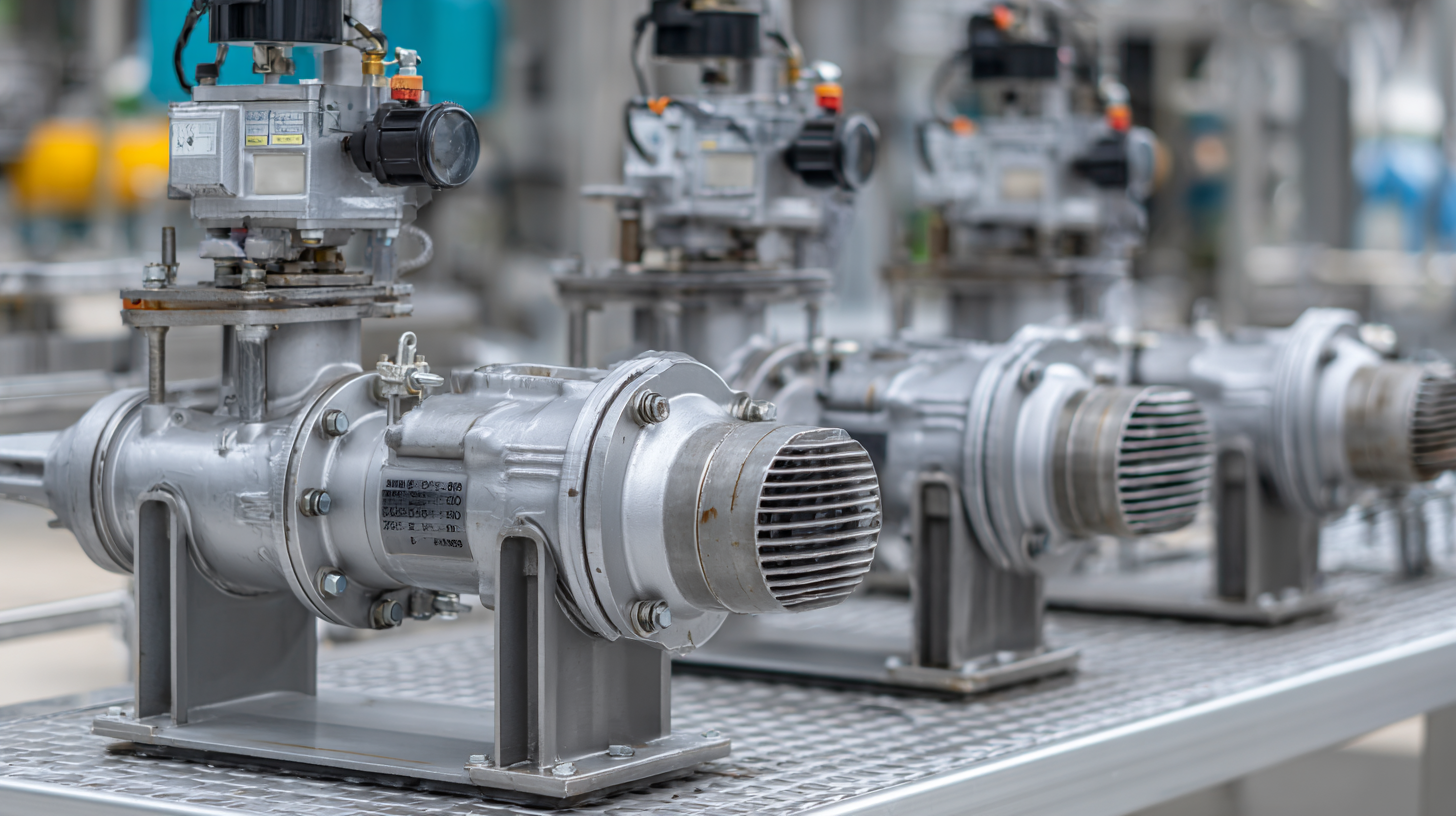

The advancement in electric chemical injection pump technology is set to transform fluid management across various industries. Leading the charge are innovations in precision control systems that enable these pumps to operate with unprecedented accuracy. By integrating smart sensors and real-time data analytics, operators can monitor pump performance and chemical dosing, ensuring optimal efficiency and reducing waste. This shift not only enhances operational reliability but also minimizes environmental impact, aligning with the growing demand for sustainable practices.

Another significant innovation is the development of advanced materials and design features that improve the durability and adaptability of electric chemical injection pumps. With robust construction and resistance to corrosive substances, these pumps can function effectively in diverse and challenging environments. Additionally, features such as modular designs and easy maintenance access reduce downtime and operational costs. As industries increasingly adopt these cutting-edge technologies, the future of fluid management will see enhanced performance, reliability, and sustainability, positioning electric chemical injection pumps as a cornerstone in modern applications.

Challenges and Solutions in Implementing Electric Chemical Injection Systems

The implementation of electric chemical injection systems presents several challenges that organizations must navigate to fully leverage their potential. One significant hurdle is integrating these systems into existing infrastructure. Legacy systems often lack compatibility with new electric pumps, leading to potential operational disruptions and increased costs during the upgrade process. Furthermore, this integration requires thorough training for personnel to ensure they are adept in managing the sophisticated control mechanisms that these electric systems demand.

Another crucial challenge is establishing reliable power supply and monitoring capabilities. Electric chemical injection pumps rely on a consistent energy source to function effectively and maintain precise dosing. Fluctuations in power supply can compromise their performance, resulting in inconsistent chemical distribution that may impact operational efficiency and safety. To combat this, companies are investing in backup systems and advanced monitoring technologies that enable real-time data collection and remote management, thus enhancing the reliability and effectiveness of electric chemical injection systems. Addressing these challenges is vital for realizing the full benefits of electric pumps in fluid management.

Future Trends: The Role of Sustainability in Fluid Management Technologies

The future of fluid management technologies is increasingly leaning towards sustainability, particularly in the realm of electric chemical injection pumps. As industries face mounting pressure to reduce their carbon footprints, the integration of eco-friendly practices within pumping solutions is becoming paramount. These advanced systems not only enhance operational efficiency but also incorporate materials and processes that minimize environmental impact, aligning with broader goals of sustainable development.

Tips for implementing sustainable fluid management include evaluating the energy source used for pumps, opting for renewable options whenever possible. Additionally, companies should seek to utilize biodegradable or less harmful chemicals in their processes. Regular maintenance of equipment can also extend the lifespan of pumps, reducing waste and promoting resourcefulness.

Furthermore, innovation in design is vital for sustainability. Manufacturers are investing in smart technologies that optimize chemical injection rates, ensuring that only what is necessary is used. This precision reduces both waste and operational costs, making sustainable practices not only responsible but economically viable for businesses. Adopting these future trends will ensure that the industry moves towards a more sustainable and efficient approach to fluid management.

Revolutionizing Fluid Management: The Future of Electric Chemical Injection Pumps

This chart illustrates the trend of electric chemical injection pump energy consumption, showing the decrease in energy usage while increasing the emphasis on sustainability from 2020 to 2025.

Related Posts

-

Unveiling the Best Chemical Pumps: A Comprehensive Comparison Guide

-

10 Essential Tips for Choosing the Right Electric Diaphragm Pump for Your Business

-

7 Essential Tips for Choosing the Right Chemical Diaphragm Pump

-

5 Best Solar Pumps for Efficient Water Management in Agriculture

-

7 Essential Tips for Choosing the Right Diaphragm Pump for Your Business Needs

-

How to Maximize Efficiency in Your Solar Pump System with Latest Technology Innovations

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.