Top 2025 Pressure Pumps: Innovative Solutions for Every Need

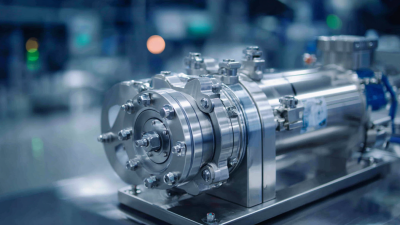

As industries evolve and demands grow, the role of pressure pumps in various applications has never been more crucial. In 2025, we are witnessing a remarkable shift in the technology and design of these essential tools, establishing them as indispensable assets across sectors such as agriculture, manufacturing, and water treatment. Leading expert in fluid dynamics, Dr. Emily Carter, emphasizes this trend, stating, “The future of pressure pumps lies in their ability to integrate smart technology, ensuring efficiency and adaptability to different operational challenges.”

Innovative solutions are emerging that cater to a diverse range of needs, highlighting the versatility of pressure pumps. From enhanced energy efficiency to advanced monitoring systems, these modern pumps are setting new standards for performance and sustainability. As industries seek to optimize their operations, the demand for cutting-edge pressure pumps will only continue to rise, making this an exciting time for both manufacturers and users alike.

In this article, we will explore the top five pressure pumps of 2025, examining how these innovative solutions are designed to meet the varied demands of the industry while pushing the boundaries of technology. Join us as we delve into the features, benefits, and applications of these remarkable machines that are shaping the future of fluid management.

Selecting the Right Pressure Pump for Your Application

Selecting the right pressure pump for your application requires a thorough understanding of your specific needs and operational conditions. Different applications, whether industrial, agricultural, or residential, demand unique features and performance capabilities from pressure pumps.

Factors such as flow rate, pressure requirements, and fluid characteristics play a critical role in this selection process.

For example, agricultural settings may prioritize high flow rates for irrigation, while industrial processes could require pumps capable of handling corrosive fluids or delivering precise pressure levels.

Selecting the right pressure pump for your application requires a thorough understanding of your specific needs and operational conditions. Different applications, whether industrial, agricultural, or residential, demand unique features and performance capabilities from pressure pumps.

Factors such as flow rate, pressure requirements, and fluid characteristics play a critical role in this selection process.

For example, agricultural settings may prioritize high flow rates for irrigation, while industrial processes could require pumps capable of handling corrosive fluids or delivering precise pressure levels.

Moreover, considering the efficiency and energy consumption of the pump is vital. Modern pressure pumps are designed with innovative solutions that enhance performance while minimizing operational costs. Users should look for pumps with adjustable speed controls, smart automation features, and robust materials that can withstand varying environmental conditions. Ultimately, understanding the specific requirements of your application will enable you to choose a pressure pump that not only meets your current demands but also provides reliability and flexibility for future needs.

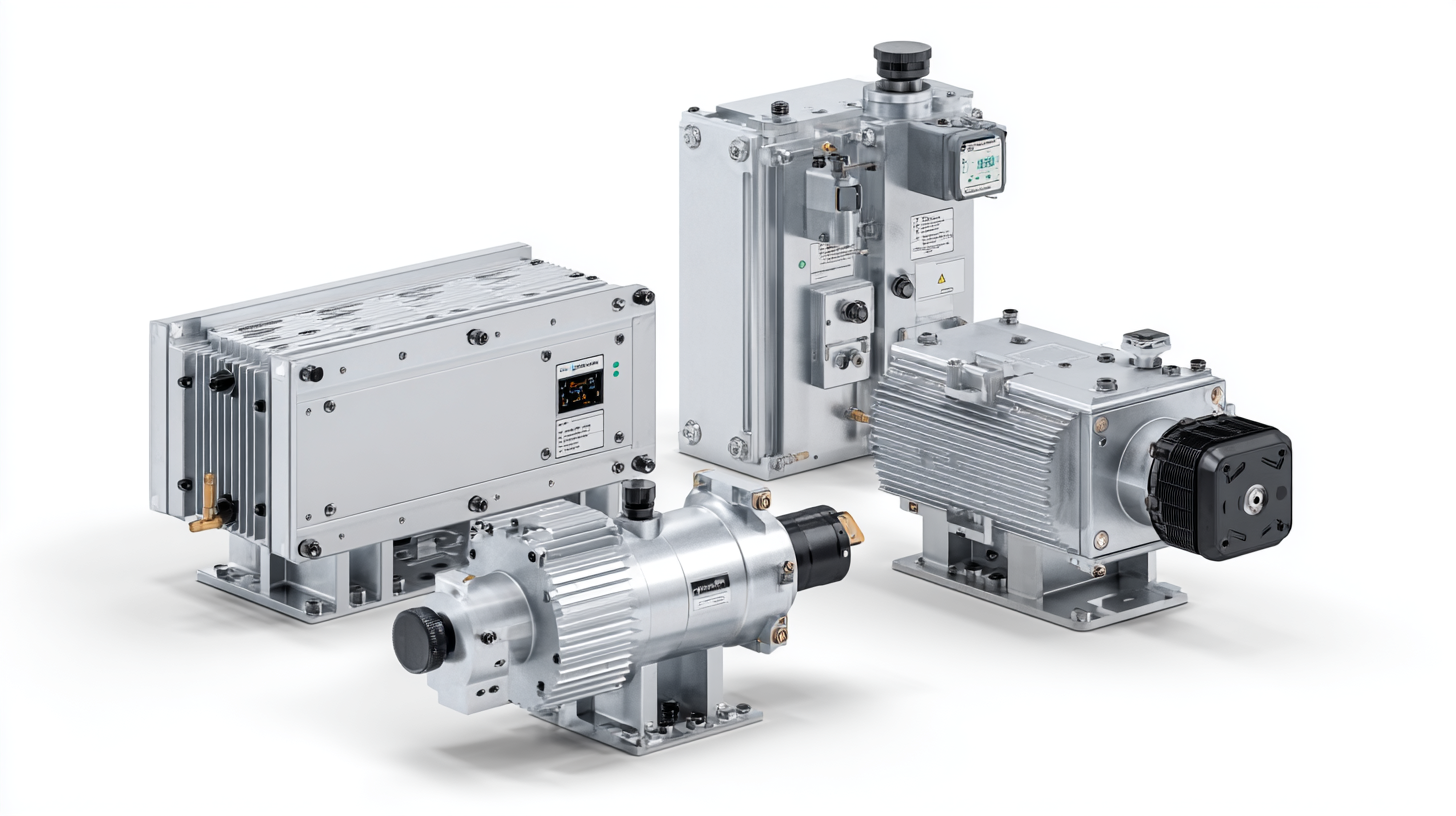

Understanding Different Types of Pressure Pumps and Their Uses

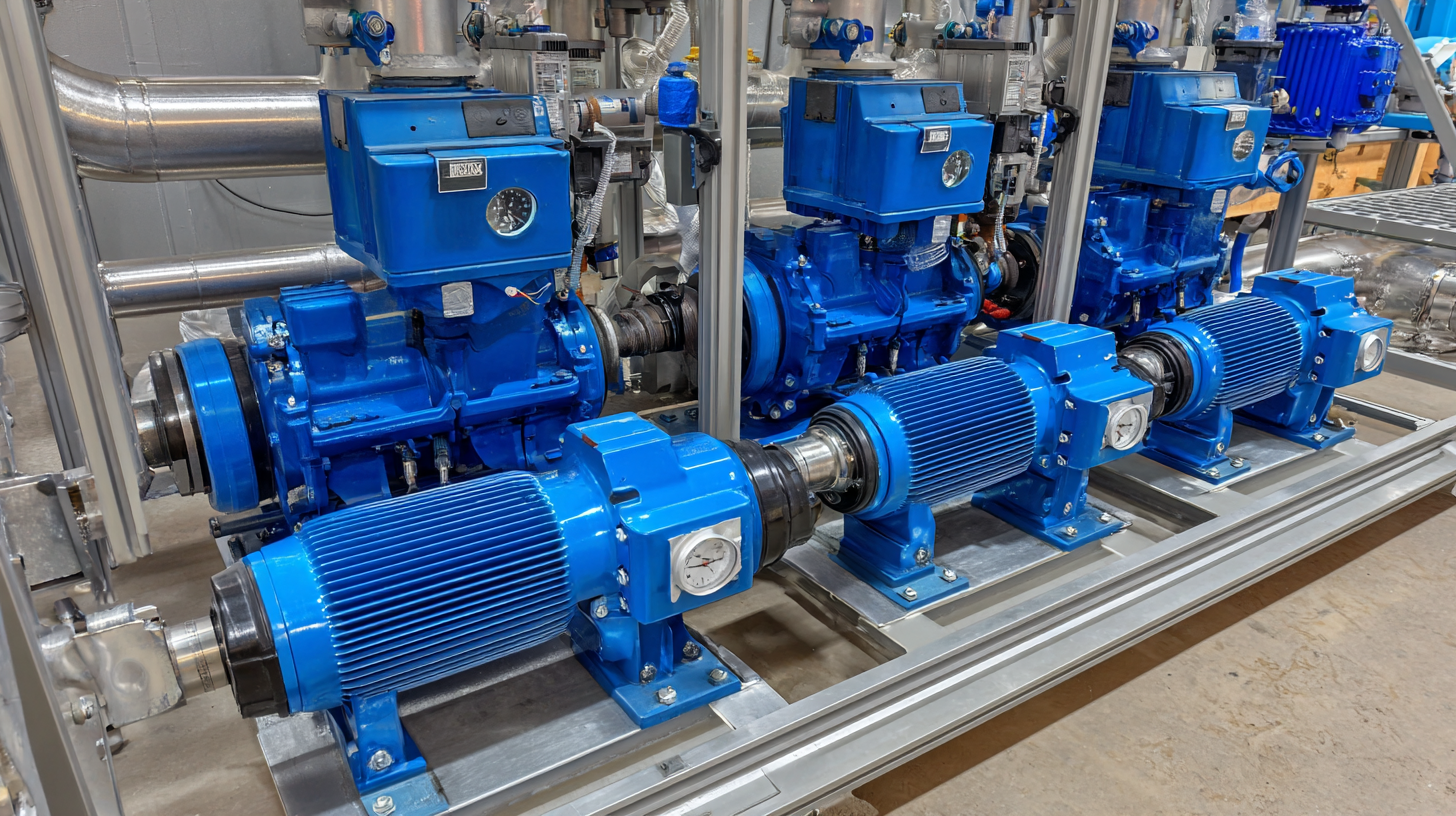

Pressure pumps are essential tools in various industries, each designed to meet specific needs. Understanding the different types of pressure pumps is crucial for selecting the right one for a particular application. Positive displacement pumps, for instance, are ideal for situations requiring high pressure and consistent flow, making them perfect for hydraulic systems and oil transfer. On the other hand, centrifugal pumps are known for their efficiency and ability to handle larger volumes of fluid, making them suitable for applications like irrigation and water treatment.

In addition to these common types, specialized pumps like booster pumps and submersible pumps cater to specific demands. Booster pumps are employed to increase water pressure in residential or commercial setups, ensuring adequate flow rates for showerheads, appliances, and irrigation systems. Submersible pumps, as their name suggests, operate underwater, making them crucial for draining flooded areas or managing wastewater in sewage systems.

By recognizing the various types of pressure pumps and their respective uses, businesses and homeowners alike can make informed decisions to optimize their systems and enhance operational efficiency.

Key Features to Look for in Innovative Pressure Pump Designs

When exploring innovative pressure pumps in 2025, several key features should be prioritized to ensure optimal performance and efficiency. First, variable speed control is essential as it allows for precise adjustments based on specific application demands. This feature not only enhances energy efficiency but also extends the pump's lifespan by reducing wear during operation. Additionally, advanced materials, such as corrosion-resistant alloys and composites, are increasingly important in design, providing durability and reliability in harsh environments.

Another crucial aspect to consider is the integration of smart technology. Pressure pumps equipped with IoT capabilities can provide real-time monitoring and diagnostics, enabling users to track performance and identify maintenance needs proactively. This connectivity enhances operational efficiency and minimizes downtime by allowing for timely interventions. Furthermore, compact and modular designs facilitate easier installation and maintenance, making pressure pumps more versatile across various applications, from industrial use to household systems.

Maintenance Tips for Ensuring Optimal Performance of Pressure Pumps

When it comes to maximizing the performance of pressure pumps, regular maintenance is crucial. Industry studies indicate that improper maintenance can reduce a pump's lifespan by up to 50%, resulting in costly replacements and downtime. One key maintenance tip is to routinely inspect seals and gaskets for wear, as these components are essential in preventing leaks and maintaining pressure. A report from the Hydraulic Institute suggests that maintaining optimal seal conditions not only enhances efficiency but can also save facilities approximately 10% on energy costs over time.

Another important aspect of pressure pump maintenance is monitoring performance parameters such as flow rate and pressure output. The American Society of Mechanical Engineers (ASME) recommends that systems should be regularly calibrated to ensure they operate within specified parameters. Deviations can signal issues such as clogging or wear, which should be addressed immediately to prevent catastrophic failures. Additionally, implementing a vibration analysis program can help identify early signs of mechanical issues, potentially saving organizations thousands in repairs and operational disruptions. By focusing on these maintenance strategies, industries can ensure their pressure pumps operate effectively and economically throughout their service lives.

Future Trends in Pressure Pump Technology and Their Impact on Industries

As we look toward 2025, the landscape of pressure pump technology is set to undergo significant transformation, driven by innovations that cater to diverse industrial needs. The advent of IoT-enabled pressure pumps offers real-time monitoring and data analytics, allowing for optimized performance and predictive maintenance. Industries such as agriculture, manufacturing, and water management will benefit from these advancements, enhancing efficiency and reducing operational costs.

Tips for incorporating new pressure pump technologies include assessing your specific operational requirements and exploring automation features that can be integrated into existing systems. Ensure that your chosen solution is scalable, allowing for future upgrades as technology evolves.

The push for sustainability is also shaping the future of pressure pumps. Innovations like energy-efficient designs and eco-friendly materials are becoming essential for companies aiming to minimize their environmental impact. It's crucial for businesses to stay informed about these trends and consider how adopting such technologies can improve both their bottom line and their ecological footprint.

Top 2025 Pressure Pumps: Innovative Solutions for Every Need

| Pump Type | Max Pressure (bar) | Flow Rate (L/min) | Applications | Energy Efficiency |

|---|---|---|---|---|

| Centrifugal Pump | 25 | 150 | Water Supply, HVAC Systems | High Efficiency |

| Positive Displacement Pump | 40 | 80 | Oil Transfer, Chemical Processing | Moderate Efficiency |

| Diaphragm Pump | 20 | 60 | Food & Beverage, Water Treatment | High Efficiency |

| Submersible Pump | 15 | 100 | Wastewater, Irrigation | Moderate Efficiency |

| Gear Pump | 30 | 70 | Fuel Delivery, Hydraulic Systems | High Efficiency |

Related Posts

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

Exploring Check Valve Innovations at the 2025 China Import and Export Fair

-

Top 10 Benefits of Using Pump Systems for Efficient Fluid Management

-

Harnessing Industry Growth Through Motor Pumps at the 138th Canton Fair 2025

-

How to Choose the Right Electric Pump for Your Specific Needs

-

2025 How to Choose the Right Liquid Pump for Your Industrial Needs

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.