Top Types of Pumps for Efficient Water Movement and Management?

Water management is crucial for various applications. Efficient systems help conserve resources and enhance productivity. The right pump water solution can make all the difference. Different types of pumps are designed to optimize water flow.

These devices range widely in design and function. Submersible pumps are great for deep wells. Solar-powered models offer eco-friendly options. Each type has its strengths and weaknesses. Understanding these can help users choose wisely.

Choosing the right pump water system is not always straightforward. Users must consider factors like pressure, flow rate, and energy source. Misjudgments can lead to inefficiencies and wasted resources. Careful evaluation is key to effective water management.

Overview of Water Pump Types Used in Various Industries

When discussing water pumps used across various industries, it's essential to examine their diversity and efficiency. Centrifugal pumps, for example, are popular in municipal water systems, where they can handle large volumes. According to a report by the Hydraulic Institute, about 75% of pumps in use today are centrifugal. These pumps are efficient and can move water effectively across different elevations.

Another noteworthy type is positive displacement pumps. They are vital in the oil and gas sector, where precise fluid transfer is crucial. These pumps can handle viscous fluids and maintain a consistent flow rate. Data from the American Petroleum Institute indicates that around 60% of fluid transfer operations benefit from these pumps.

However, efficiency isn't always guaranteed. Some systems may not return the expected energy savings. Many industries face challenges with pump maintenance, leading to performance degradation. This concern highlights the importance of regular assessments and advancements in technology to enhance pump reliability and efficiency.

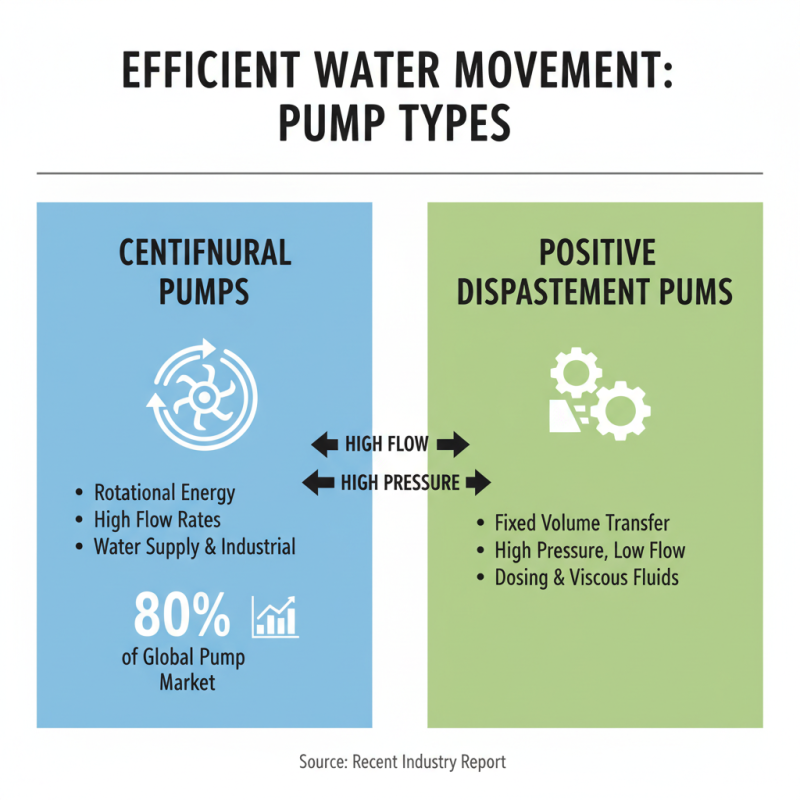

Comparison of Centrifugal Pumps and Positive Displacement Pumps

When considering pumps for efficient water movement, centrifugal pumps and positive displacement pumps stand out. Centrifugal pumps leverage rotational energy to transfer fluids. They excel in applications requiring high flow rates. According to a recent industry report, they make up about 80% of the global pump market. These pumps are ideal for water supply and industrial systems.

On the other hand, positive displacement pumps excel in low-flow, high-pressure applications. They operate by trapping a fixed volume of fluid and forcing it out, regardless of resistance. This makes them suitable for applications where precise dosing is crucial. A study found that positive displacement pumps can achieve efficiencies exceeding 90% in these contexts.

Tips: When selecting a pump, consider flow requirements. Also, assess your pressure needs. Remember, choosing the right type impacts energy consumption and system performance. Both pump types have strengths and weaknesses, so understanding your specific application is key. Consider potential maintenance challenges as well. Some centrifugal pumps may require more upkeep due to wear on wear parts. In comparison, positive displacement pumps may face issues with fluid viscosity and pulsation. Balancing efficiency and ease of maintenance is essential for long-term performance.

Key Performance Metrics for Efficient Water Pumps

When evaluating pumps for water movement, several key performance metrics must be considered. Efficiency is crucial; pumps can operate at 60-85% efficiency. A lower efficiency may lead to increased operational costs over time. A study by the Hydraulic Institute reveals that energy costs can constitute up to 90% of the total lifecycle expense of a pump. Thus, selecting an efficient model can deliver significant long-term savings.

Flow rate is another important metric. It determines how much water a pump can move in a given time. A high flow rate is beneficial for large operations but can result in increased wear and tear. According to the American Society of Civil Engineers, improperly sized pumps can lead to a 25% drop in performance. Regular assessments of flow rates can help maintain optimal performance and avoid costly repairs.

Other factors include pressure output and durability. A pump must deliver adequate pressure for its intended application. Poor pressure can cause issues, including reduced system performance. Additionally, material quality affects the lifespan of a pump. Pumps in corrosive environments must be properly designed. Many operators overlook these aspects, leading to inefficient operations and unexpected failures.

Top Types of Pumps for Efficient Water Movement and Management

| Pump Type | Flow Rate (GPM) | Head (Feet) | Efficiency (%) | Power Requirement (HP) |

|---|---|---|---|---|

| Centrifugal Pump | 10-500 | 20-200 | 65-85 | 1-50 |

| Positive Displacement Pump | 5-300 | 10-150 | 70-90 | 2-40 |

| Submersible Pump | 30-1000 | 15-300 | 60-80 | 1-60 |

| Diaphragm Pump | 1-100 | 5-50 | 55-90 | 0.5-15 |

Applications of Submersible Pumps in Wastewater Management

Submersible pumps play a vital role in wastewater management. These pumps are designed to operate underwater, effectively moving water from lower to higher elevations. According to industry reports, around 80% of wastewater treatment facilities globally utilize submersible pumps for efficiency. They consume less energy compared to surface pumps. This efficiency reduces operational costs, yet it's crucial to monitor pump conditions regularly.

In municipalities, submersible pumps are common in sewage systems. They manage and transport wastewater, ensuring it reaches treatment plants. A study indicated that improper maintenance leads to a 30% increase in pump failures. Monitoring the equipment's performance can prevent costly breakdowns. Operators often overlook this, placing unnecessary strain on the system.

Not all submersible pumps are created equally for every application. Some may struggle with solids and debris in sewage, leading to clogs. As per estimates, about 15% of operators experience inefficient waste movement due to improper pump selection. Regular evaluations and updates to pump technology can significantly enhance performance. Attention to detail is essential for optimizing operations in wastewater management.

Top Types of Pumps for Efficient Water Movement and Management

This chart illustrates the distribution of different types of pumps used in wastewater management applications. The data showcases the percentage share of each pump type commonly utilized.

Emerging Technologies in Pump Design for Sustainability

Emerging technologies in pump design are reshaping water management practices. These innovations focus on enhancing efficiency and sustainability. One notable development is the use of smart sensors. These sensors monitor real-time data, optimizing water flow as needed. This technology can significantly reduce water waste.

Another area of progress involves renewable energy integration. Solar-powered pumps are becoming more common. They provide an eco-friendly solution for remote areas. This minimizes reliance on traditional power sources. However, the initial investment can be high, which poses challenges for some users.

Additionally, 3D printing is revolutionizing pump parts manufacturing. It allows for rapid prototyping, reducing production time and costs. This method can lead to unique designs that improve performance. Still, inconsistency in material strength raises concerns. Further testing is necessary to ensure reliability.

Related Posts

-

How to Choose the Right Pressure Pumps for Maximum Efficiency in Your Applications

-

How to Effectively Pump Water for Your Home Garden?

-

Why Are Industrial Pumps Essential for Manufacturing Efficiency?

-

5 Best Advantages of Diaphragm Pumps in Industrial Applications

-

Liquid Pump Innovations and Industry Trends Highlighted at 2025 China Import and Export Fair

-

The Future of Treatment Pumps Innovations Transforming Healthcare Delivery

Whether your solution requires a single pumping application or an expansive engineered system,

CheckPoint is committed to becoming your partner in excellence.