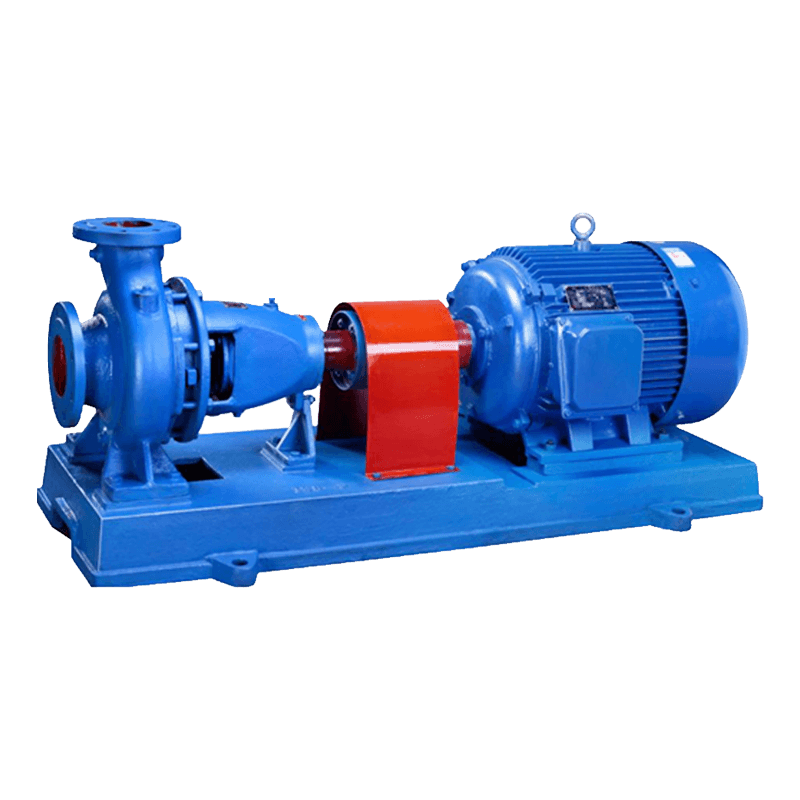

Unmatched Quality in Best Centrifugal Pump Parts: The Trusted Choice of Global Industries

In today's industrial landscape, the efficiency and reliability of machinery play a pivotal role in ensuring optimal operations across various sectors. Among these, centrifugal pumps remain a cornerstone of fluid movement in industries ranging from water treatment to chemical manufacture. According to the Global Centrifugal Pump Market report, the market is projected to grow to USD 45 billion by 2025, driven by increasing demand for effective fluid handling solutions. However, the performance of centrifugal pumps heavily relies on the quality of their components. Subpar centrifugal pump parts can lead to frequent breakdowns, increased downtime, and significant costs. With the stakes so high, sourcing unmatched quality centrifugal pump parts is not just a preference but a necessity for global industries aiming to maintain operational continuity and efficiency. This blog delves into the common problems industries face with inferior components and highlights the importance of investing in high-quality parts to ensure optimal performance and longevity of centrifugal pumps.

Understanding the Importance of Quality in Centrifugal Pump Parts

When it comes to centrifugal pump parts, the significance of quality cannot be overstated. These components play a crucial role in the overall performance and reliability of the pump, affecting everything from efficiency to lifespan. Industries across the globe depend on highly efficient and durable pumps to maintain operational continuity, making the selection of quality parts paramount. Low-quality components may save costs in the short term but can lead to catastrophic failures and expensive downtimes.

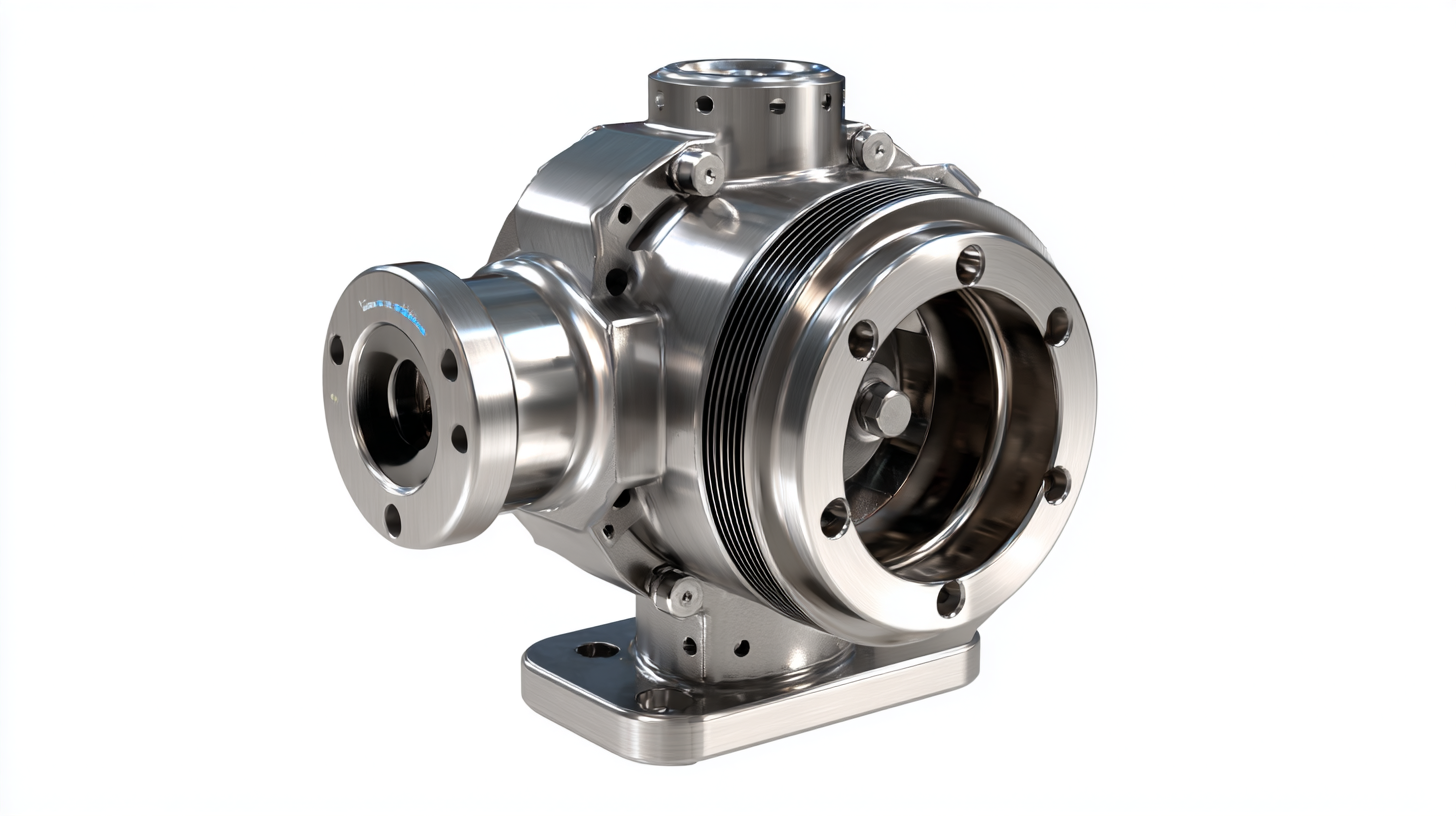

Tip: Always examine the materials used in centrifugal pump parts. High-grade stainless steel or specialized alloys often provide superior resistance to corrosion and wear, ensuring that your pumps run smoothly over time.

Tip: Always examine the materials used in centrifugal pump parts. High-grade stainless steel or specialized alloys often provide superior resistance to corrosion and wear, ensuring that your pumps run smoothly over time.

Investing in high-quality centrifugal pump parts not only enhances performance but also ensures compliance with industry standards. Pumps equipped with reliable parts contribute to a safer work environment and reduced maintenance costs. As industries evolve, the need for reliable equipment becomes more pressing.

Tip: When sourcing pump parts, prioritize suppliers who offer warranties or guarantees. This can provide peace of mind, knowing that you are covered in case of defects or performance issues.

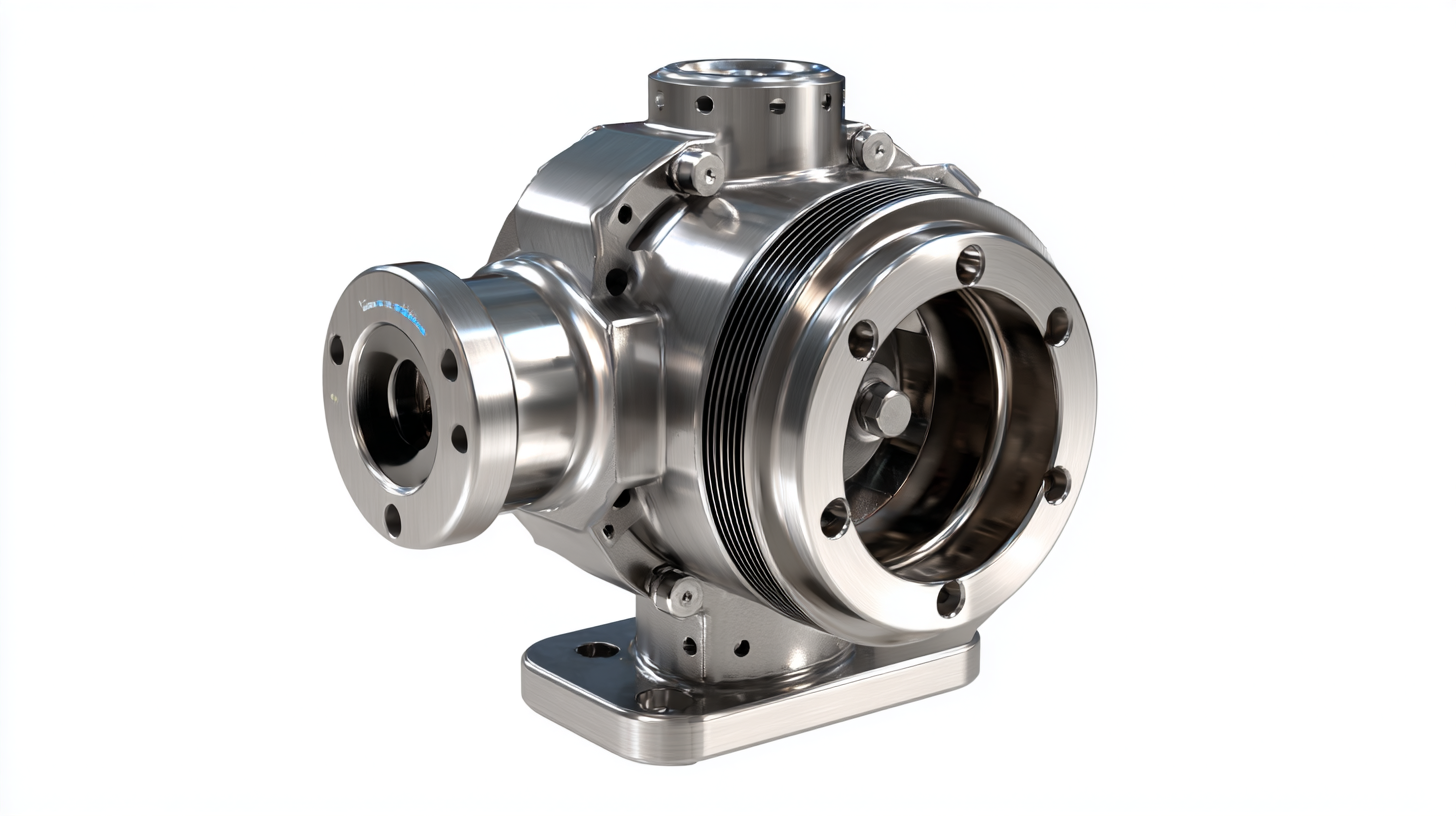

Key Features to Look for in Premium Centrifugal Pump Components

When selecting centrifugal pump parts, several key features distinguish premium components from standard offerings. First and foremost, materials matter significantly. High-quality pump components are often crafted from corrosion-resistant materials such as stainless steel or specialized alloys that can withstand harsh chemicals and high temperatures. This durability not only prolongs the lifespan of the pump but also ensures reliable operation in demanding industrial environments.

Another essential feature to consider is precision engineering. Top-tier centrifugal pump parts undergo rigorous testing and are manufactured using advanced technologies to ensure perfect tolerances. This attention to detail minimizes wear and tear, enhances efficiency, and reduces the need for frequent maintenance. Additionally, compatibility with various pump configurations allows for seamless integration and optimal performance, making these parts a trusted choice for industries worldwide. Investing in these high-quality components ultimately translates to more efficient operations and significant cost savings in the long run.

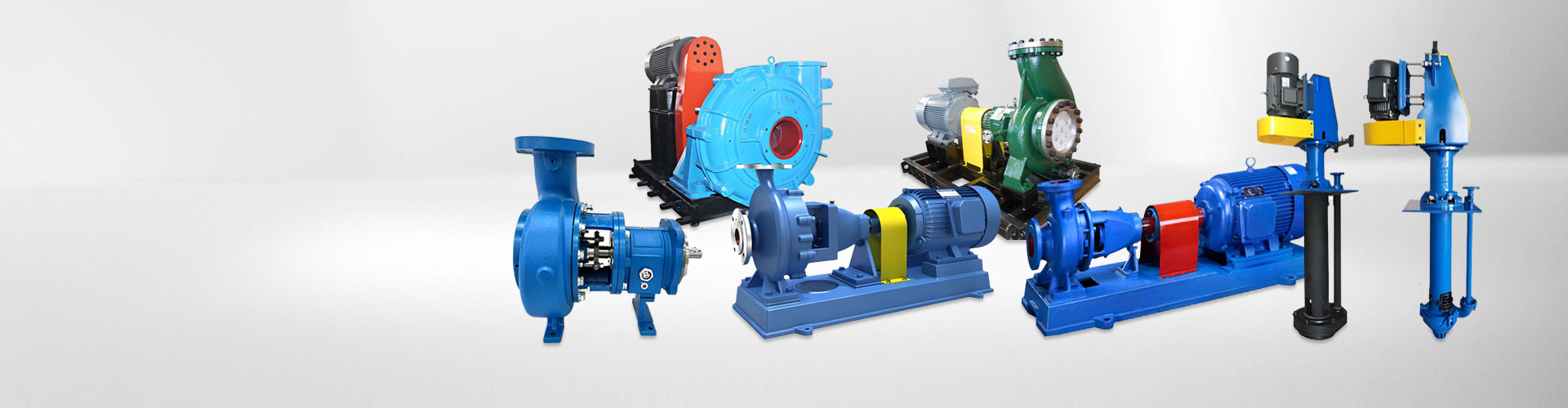

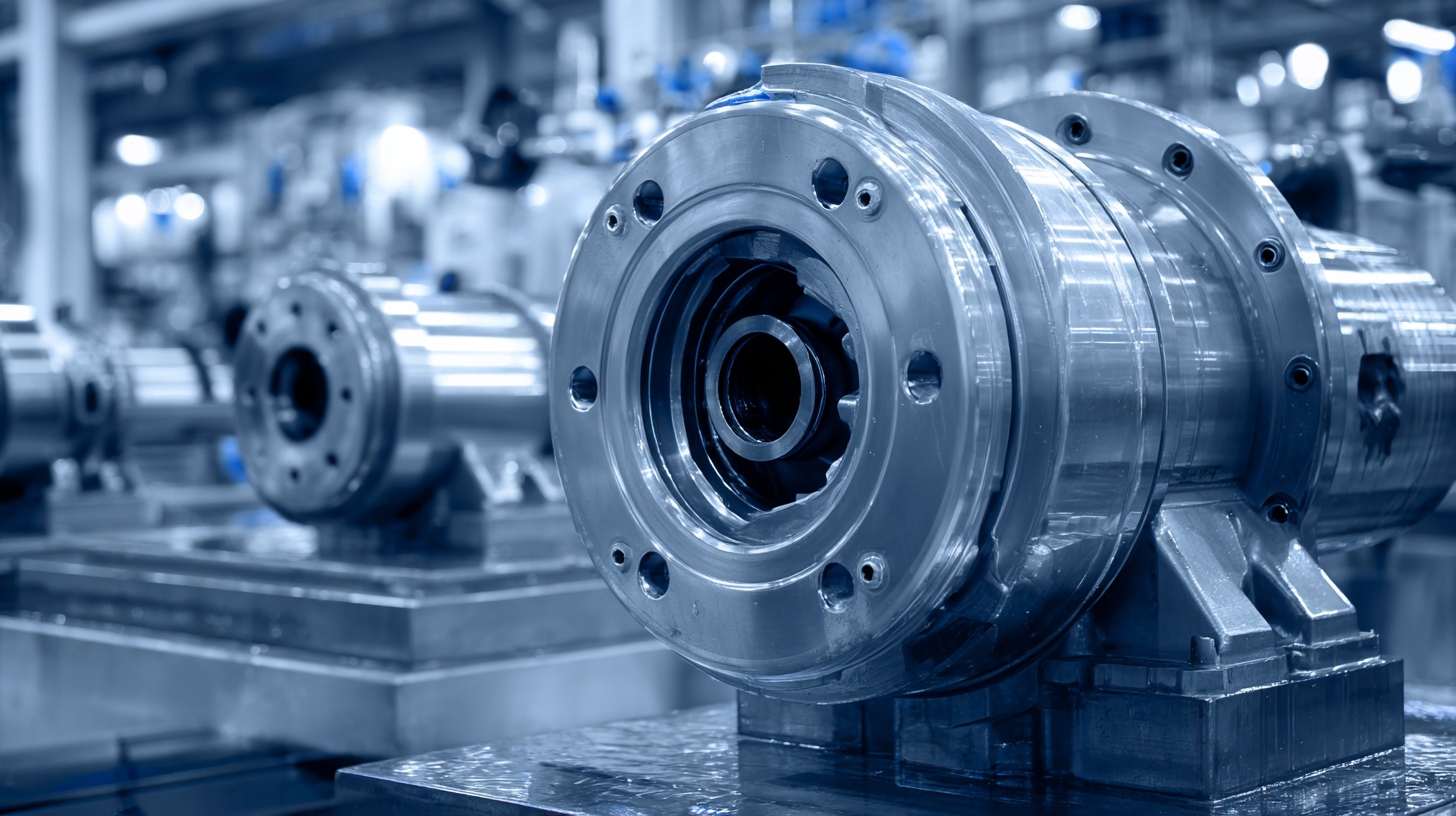

Comparing Leading Brands: Which Centrifugal Pump Parts Stand Out?

When it comes to selecting centrifugal pump parts, the choices can be overwhelming, especially with so many leading brands on the market. According to a recent industry report from Grand View Research, the global centrifugal pump market is projected to reach $38.4 billion by 2025, indicating a healthy demand for high-quality components. Among the top brands, Flowserve, KSB, and Grundfos continually stand out, not only for their innovative designs but also for their commitment to reliability and efficiency.

Flowserve’s centrifugal pump parts, for instance, enjoy a reputation for exceptional durability, with materials engineered to withstand extreme pressures and abrasive conditions. KSB has made significant strides in energy efficiency, boasting pumps that can reduce operational costs by up to 30%, according to a 2021 study by the International Energy Agency. Similarly, Grundfos leads in smart technology integration, providing solutions that enhance monitoring and maintenance, ultimately extending the lifespan of their pump parts. In an industry where equipment failure can lead to costly downtime, investing in components from top-tier brands is not just a preference but a necessity for global industries aiming for unmatched quality and performance.

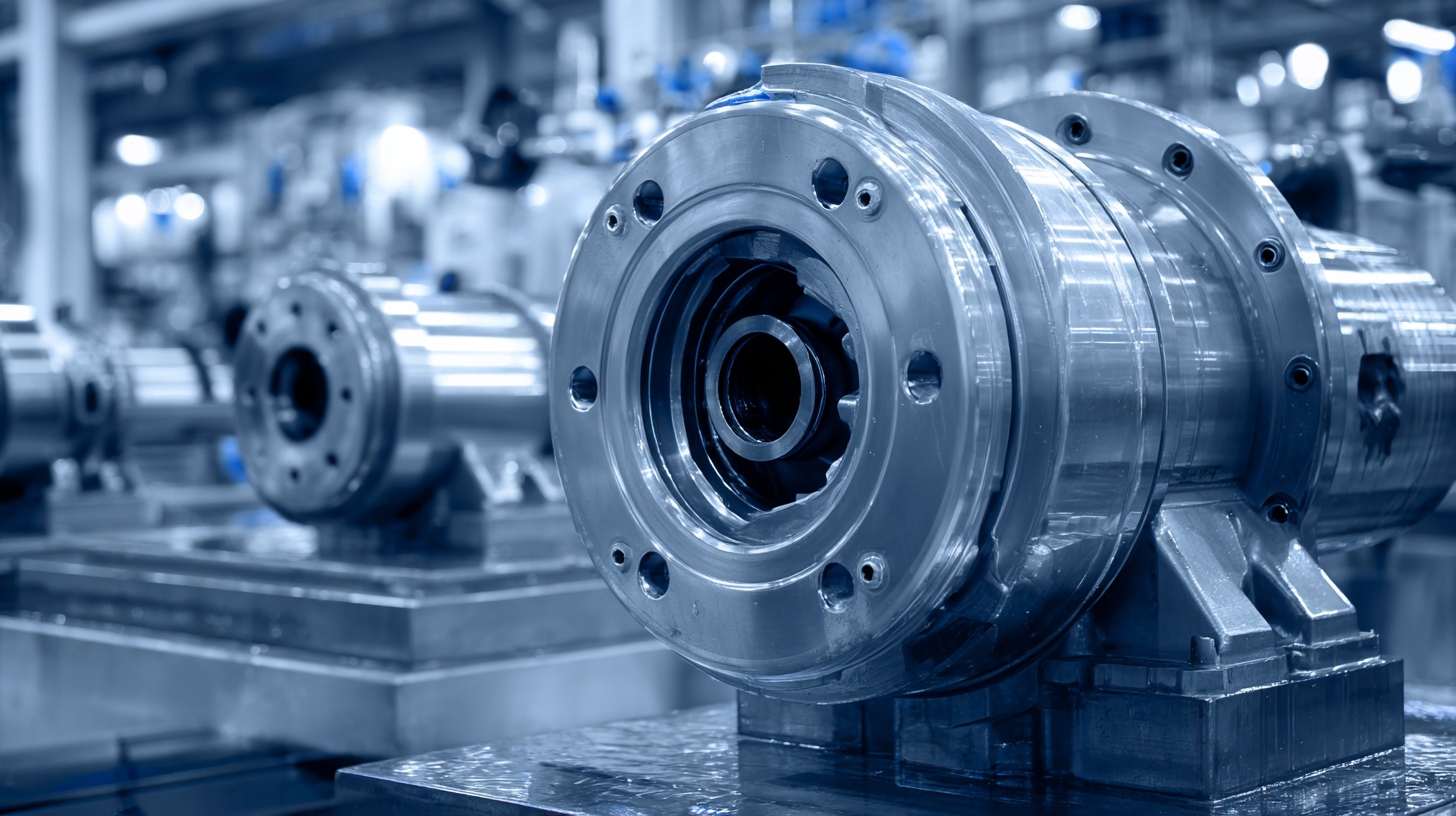

Common Issues with Low-Quality Pump Parts and Their Impact

When it comes to centrifugal pumps, the quality of parts plays a critical role in overall performance and longevity. Low-quality pump parts can lead to common issues such as improper sealing, excessive wear, and even catastrophic failures that halt operations. These compromises not only result in increased maintenance costs but can also affect the overall efficiency of the pump system, ultimately impacting production timelines across various industries.

To mitigate the risks associated with low-quality pump parts, regular inspections are crucial. Maintaining a schedule for checking seals, bearings, and impellers can identify potential problems early on. Additionally, investing in high-quality parts from trusted manufacturers can significantly reduce the likelihood of breakdowns. Always compare specifications and materials used in pump components to ensure they meet industry standards.

Another effective strategy is to train your maintenance team on recognizing the signs of wear and tear. Understanding the common issues that arise from using subpar parts can empower your team to take preventive measures. By focusing on quality and being proactive about maintenance, industries can avoid costly disruptions and ensure smooth operation of their centrifugal pumps.

Common Issues with Low-Quality Pump Parts and Their Impact

Maintenance Tips to Extend the Life of Your Centrifugal Pump Parts

Centrifugal pumps are vital components across various industries, and maintaining them effectively is crucial for ensuring longevity and reliability. One of the best ways to extend the life of your centrifugal pump parts is by implementing predictive maintenance. This practice involves closely monitoring the pumps' performance and condition, allowing for timely interventions before minor issues escalate into major failures.

Regular inspections can identify early signs of wear and potential malfunction. Pay attention to the pump's vibration and noise levels, as changes in these metrics can indicate problems. Additionally, maintaining the correct fluid viscosity and ensuring that the pump operates within its designed parameters are essential to preventing mechanical failures.

Another tip is to use high-quality materials for pump components, as advanced coatings can enhance resistance to cavitation damage. Upgrading to superior impeller materials can significantly improve the pump's durability, reducing the frequency of repairs and downtime. Ensuring proper maintenance schedules and utilizing innovative technology for monitoring can further enhance the operational efficiency and longevity of centrifugal pumps, making them a trusted choice across global industries.

Unmatched Quality in Best Centrifugal Pump Parts: The Trusted Choice of Global Industries

| Part Name |

Material |

Common Applications |

Maintenance Tips |

Expected Lifespan |

| Impeller |

Cast Iron, Stainless Steel |

Water, Chemicals, Oil |

Regular cleaning, Check wear |

5-10 years |

| Volute |

Plastic, Stainless Steel |

Water, Slurry |

Inspect for cracks, Ensure proper alignment |

7-12 years |

| Shaft |

Carbon Steel, Stainless Steel |

Water, Oil |

Lubricate regularly, Check for corrosion |

8-15 years |

| Pump Bearings |

Bronze, Ceramic |

Water, Chemical Processing |

Monitor temperature, Replace worn bearings |

5-10 years |

| Mechanical Seal |

Silicone Carbide, Graphite |

Water, Oil |

Inspect for wear, Ensure proper installation |

3-8 years |